System for producing high-whiteness calcined kaolin by multistage suspension calcination of coal series kaolin

A technology of coal series kaolin and calcined kaolin, applied in the direction of inorganic chemistry, non-metallic elements, silicon compounds, etc., can solve the problems of poor quality uniformity, low processing capacity, low heat utilization rate, etc., and achieve low processing cost and low energy consumption , High heat and mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

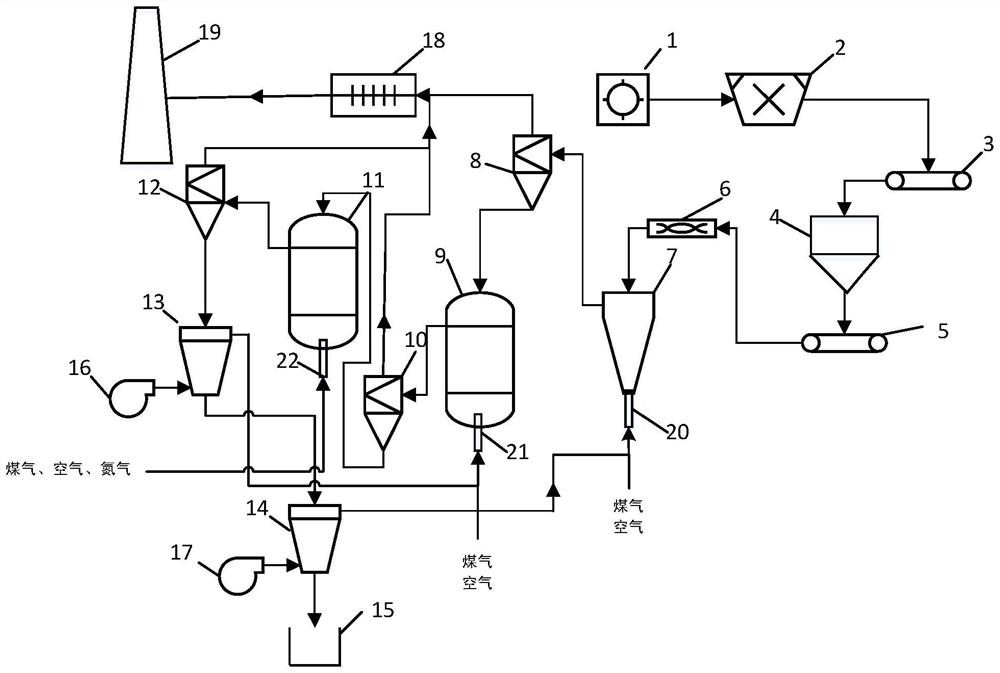

[0047] The system structure of multi-stage suspension calcination of coal series kaolin to produce high whiteness calcined kaolin is as follows: figure 1 As shown, it includes a crusher 1, a mill 2, a feeding bin 4, a screw feeder 6, a suspension dehydration calciner 7, a first cyclone separator 8, a suspension dehydration calciner 9, a second cyclone separator 10, Suspension decarburization calciner 11, third cyclone separator 12, primary cooler 13 and secondary cooler 14;

[0048] The discharge port of the crusher 1 is opposite to the feed port of the mill 2, the discharge port of the mill 2 is opposite to the first feeding belt 3, and the discharge end of the first feeding belt 3 is matched with the feeding bin 4; The discharge port of the feed bin 4 is opposite to the second feed belt 5, the second feed belt 5 matches the feed end of the screw feeder 6, and the discharge end of the screw feeder 6 is connected to the top of the suspension dehydration calciner 7 The feed po...

Embodiment 2

[0068] System structure is the same as embodiment 1;

[0069] Method is with embodiment 1, and difference is:

[0070] (1) Particle size ≤ 0.002mm in the powder accounts for 92% of the total mass; coal series kaolin contains SiO by mass percentage 2 43.55%, Al 2 o 3 38.11%, Fe 2 o 3 0.21%, CaO 0.47%, TiO 2 0.16%, MgO 0.23%, K 2 O0.31%, Na 2 O 0.22%, C 1.51%;

[0071] (2) Dehydration reaction is carried out at 250°C; the residence time of the powder in the suspension dehydration calciner is 6min;

[0072] (3) Dehydration reaction at 800°C; the residence time of the dehydrated material in the suspension dehydroxylation calciner is 20min;

[0073] (4) Decarburization reaction is carried out at 900°C, the volume flow ratio of air and nitrogen is 1:1.5; the residence time of the dehydroxylation material in the suspension decarburization calciner is 60min;

[0074] (5) After the countercurrent heat exchange between the decarbonized material and the air, the temperature o...

Embodiment 3

[0077] System structure is the same as embodiment 1;

[0078] Method is with embodiment 1, and difference is:

[0079] (1) Particle size ≤ 0.002mm in the powder accounts for 95% of the total mass; coal series kaolin contains SiO in mass percentage 2 45.16%, Al 2 o 3 36.54%, Fe 2 o 3 0.16%, CaO 0.55%, TiO 2 0.38%, MgO 0.4%, K 2 O0.36%, Na 2 O 0.35%, C 1.3%;

[0080] (2) Dehydration reaction is carried out at 300°C; the residence time of the powder in the suspension dehydration calciner is 2min;

[0081] (3) Dehydration reaction at 900°C; the residence time of the dehydrated material in the suspension dehydroxylation calciner is 10 minutes;

[0082] (4) Decarburization reaction is carried out at 950°C, the volume flow ratio of air and nitrogen is 1:2; the residence time of the dehydration material in the suspension decarburization calciner is 40min;

[0083] (5) After the countercurrent heat exchange between the decarbonized material and the air, the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com