Bearing fault diagnosis method based on synchronous optimization of wavelet filter and MCKD by using NGAs

A wavelet filter and fault diagnosis technology, which is applied in the testing of machine/structural components, instruments, genetic laws, etc., can solve the problems of not taking into account the impact of transient faults of bearings, being vulnerable to accidental interference and difficult to ensure the overall effect of diagnosis, etc. Achieve the effect of eliminating high-amplitude accidental shocks, reducing signal transmission paths and noise interference, and ensuring effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

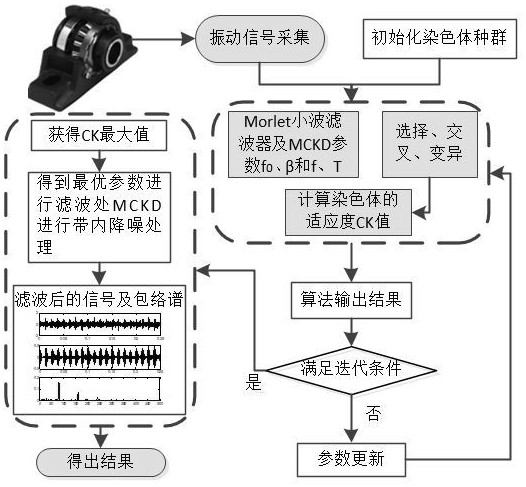

Method used

Image

Examples

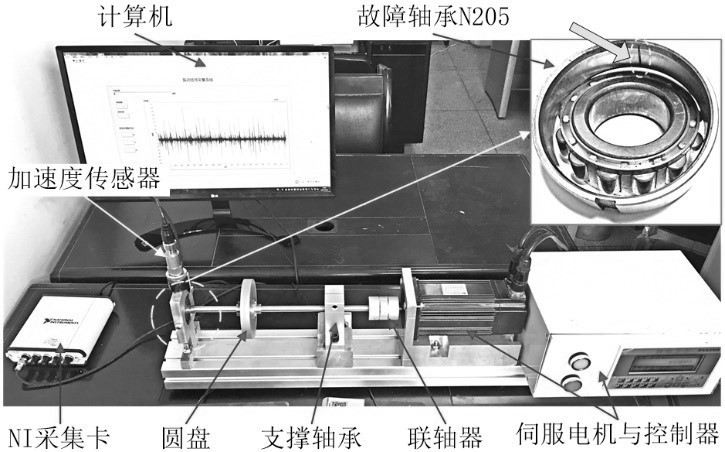

Embodiment 1

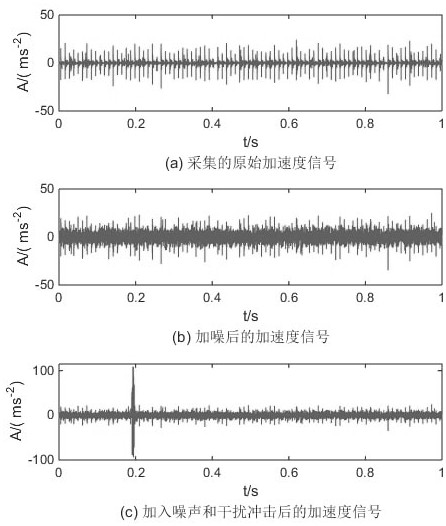

[0053] (1) Synchronous optimization of NGAs parameters: the sensor is used to collect the original vibration signal data, and the time domain waveform of the bearing outer ring fault signal is as follows: image 3 As shown in (a), the fault impact component in the time-domain waveform is more obvious, because the manual processing of grooves is relatively standard, resulting in a larger fault impact amplitude. In order to make the collected vibration signal more realistically close to the vibration signal of the bearing under complex working conditions, Gaussian random noise with an amplitude of 4 is added to the collected signal. After adding the noise, the signal is as follows: image 3 (b). In the range of 2281 to 2360 points in the signal, artificially add a period of high-amplitude occasional impact with an amplitude of 60, such as image 3 As shown in (c), set the initial conditions of niche genetic algorithm (NGAs): population size M=20, growth algebra G=100, number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com