Highly directional plano-concave lens with non-uniform thickness enz metamaterial sandwich layer

A plano-concave lens and metamaterial technology, applied in antennas, electrical components, etc., can solve the problems of difficult impedance matching, complex lens antenna design structure, etc., and achieve the effects of fewer devices, low cost, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

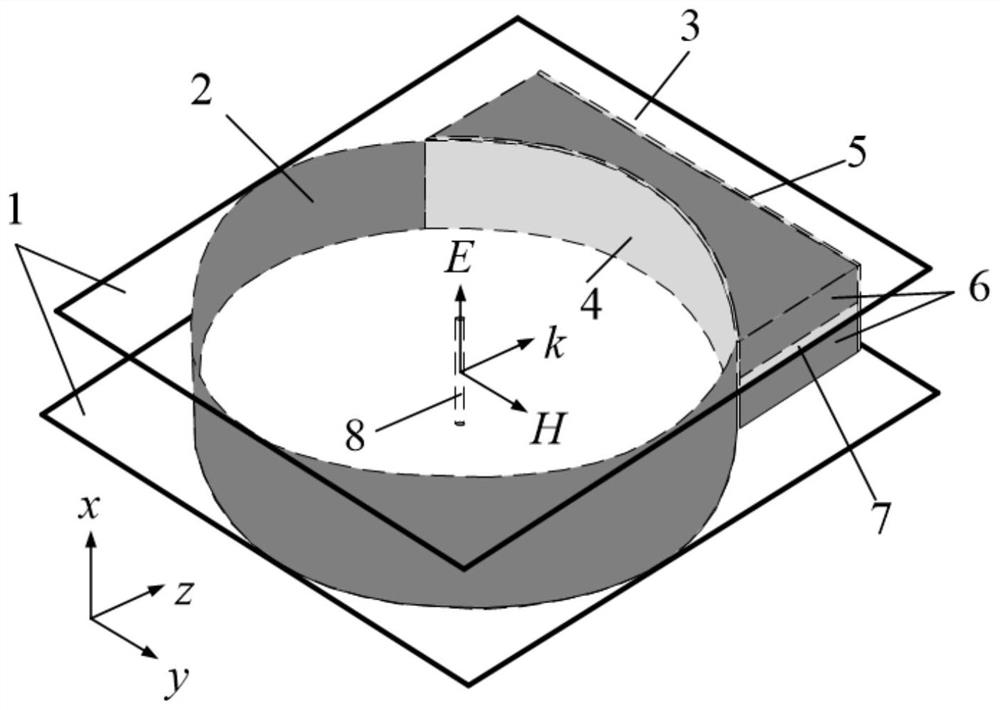

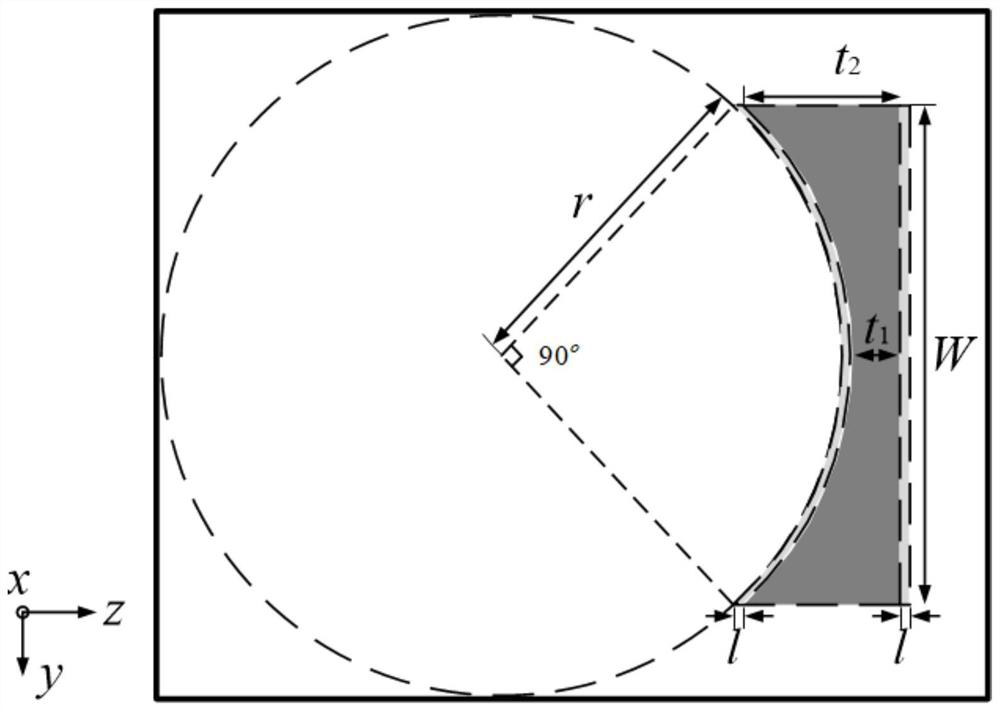

[0037] Example 1, a highly directional plano-concave lens with a non-uniform thickness ENZ metamaterial sandwich layer with a working frequency of 67 GHz.

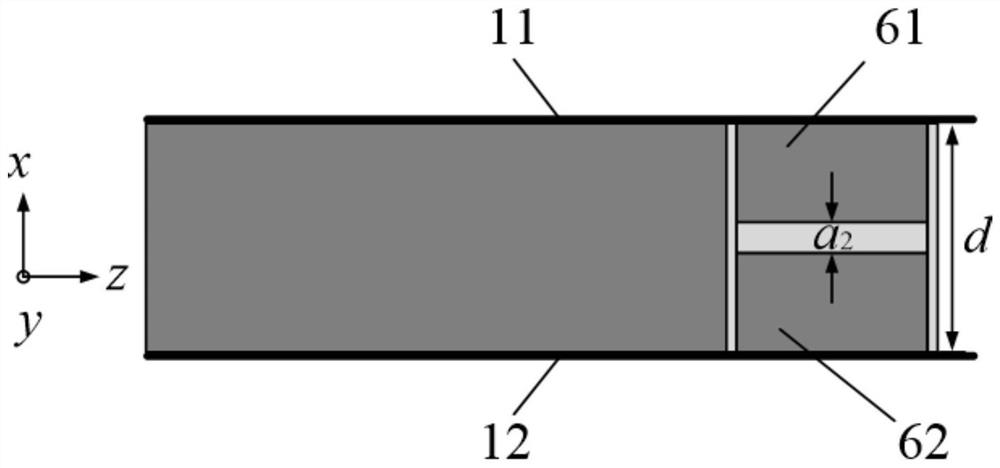

[0038] The embodiment of the present invention includes: the metal reflective surface 2 of equal height and the flat-concave lens 3 are arranged in the upper metal plate 11 and the lower metal plate 12 of the parallel plate waveguide 1, and the height d=20mm. The metal reflective surface 2 and the upper metal plate 11 and the lower metal plate 12 of the parallel plate waveguide 1 have a thickness of 0.1 mm, the metal reflective surface 2 and the flat-convex lens 3 form a closed circle, and the metal reflective surface accounts for three quarters of the closed circle. The plano-concave lens occupies a quarter of the closed circle, and the radius of the closed circle is r=31.66mm. The incident surface of the plano-concave lens 3 is a concave surface, the outgoing surface is a plane, and the length of the long side of the out...

Embodiment 2

[0039] Example 2, a highly directional plano-concave lens with a non-uniform thickness ENZ metamaterial sandwich layer with a working frequency of 92.5 GHz.

[0040] The structure of the embodiment of the present invention is the same as that of Embodiment 1, and the height d of the metal reflective surface 2 and the plano-concave lens 3, the thickness of the metal reflective surface 2 and the upper metal plate 11 and the lower metal plate 12 of the parallel plate waveguide 1, the metal plate The minimum width t of the upper metal plate 61 of 6 1 , the thickness l of the concave ENZ metamaterial substrate 4 and the planar ENZ metamaterial substrate 5, the dielectric constant ε of the ENZ metamaterial r and permeability μ r , and in the formula for calculating a, the differential characteristic admittance Y of free space 0 , differential length W 1 These parameters remain unchanged, only the following parameters have been changed:

[0041] The radius r=22.93mm of the closed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com