Small-fan-angle laser line light source module

A laser line light source and fan angle technology, applied in the laser field, can solve the problems of high cost of light source modules, stray light, unclear laser lines, etc., and achieve the effect of simple manufacturing, clear light, and favorable mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

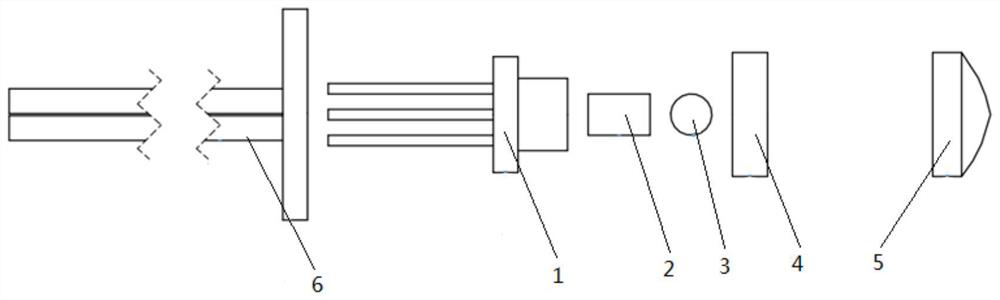

[0043] A small fan angle laser line light source module, including a pumping source 1, a laser working substance 2, a cylindrical lens 3, a beam expander 4 and a collimating mirror 5, the pumping source 1, a laser working substance 2, a cylindrical lens 3. The beam expander 4 and the collimator 5 are arranged in sequence, and the light emitted by the pump source 1 undergoes wavelength conversion, compression, beam expansion, and collimation in sequence to emit a laser line with a small fan angle.

[0044] Based on the setting of the specific positions of the pump source 1, the laser working substance 2, the cylindrical lens 3, the beam expander 4, and the collimator 5, the light is first compressed by the cylindrical lens 3 to meet the requirements of forming light with a small fan angle, and then Through the beam expander 4 and the collimator 5; different from the prior art, the present invention first passes through the cylindrical lens 3 and then through the beam expander 4 ...

Embodiment 2

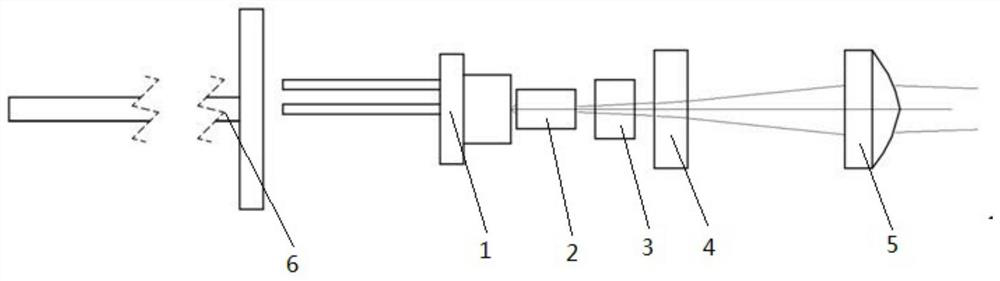

[0049] On the basis of Embodiment 1, further, the front end surface of the laser working substance 2 is located on the front focus of the cylindrical lens 3, and the back focus of the cylindrical lens 3 falls on the front focus of the beam expander 4, and the beam expander 4 The back focus of falls on the front focus of collimator mirror 5.

[0050] By strictly controlling the distances between the pump source, the laser working substance 2, the cylindrical lens 3, the beam expander 4 and the collimator 5, the purpose of saving equipment can be achieved under the premise of satisfying the formation of a small fan-angle laser line, so that the light source module of volume reduction.

[0051] Further, a coupling lens is arranged between the pump source 1 and the laser working substance 2 .

[0052] The coupling lens can focus the light emitted by the pump source 1, thereby increasing the energy density of the light injected into the laser working substance 2, so as to achieve ...

Embodiment 3

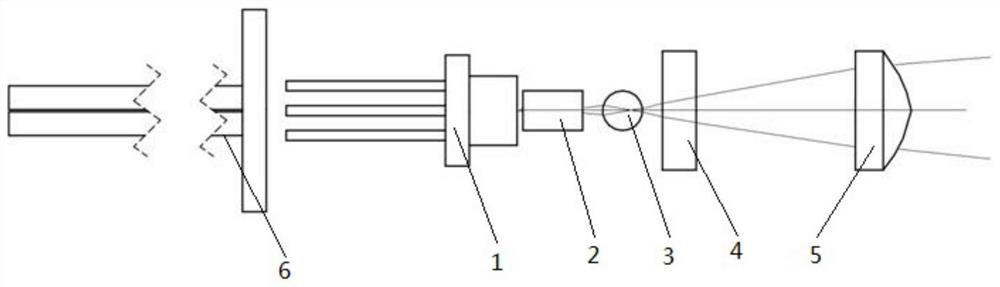

[0062] A small fan angle laser line light source module, including a pumping source 1, a laser working substance 2, a cylindrical lens 3, a beam expander 4 and a collimating mirror 5, the pumping source 1, the laser working substance 2, a cylindrical lens 3. The beam expander 4 and the collimator 5 are arranged in sequence, and the light emitted by the pump source 1 undergoes wavelength conversion, compression, beam expansion, and collimation in sequence to emit a laser line with a small fan angle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com