Treatment device and method for polymorphic organic composite pollutants

A pollutant and organic technology, applied in the field of treatment equipment for polymorphic organic compound pollutants, can solve the problems of no VOC, retention, etc., and achieve the effects of easy maintenance, elimination of liquid-solid sticking, and flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In a university cafeteria, an electrostatic oil fume removal system was used for flue gas treatment. When the moisture in the oil fume is high in winter, explosion venting often occurs, which affects normal use, and the VOC emissions of the flue gas often exceed the standard. In order to ensure stable use and solve the problem of excessive VOC emissions, the equipment of the present invention is used for transformation; the original smoke collection hood and front pipes are retained, the electrostatic oil fume removal system is removed, and a vertical U-shaped cooling pipe is added outdoors, which is made of tap water. The cooling water source, the control valve is set on the ground, the water valve is opened to control the water flow speed when the equipment is started, and the cooling water collected by the sump is used for cleaning and sanitary water.

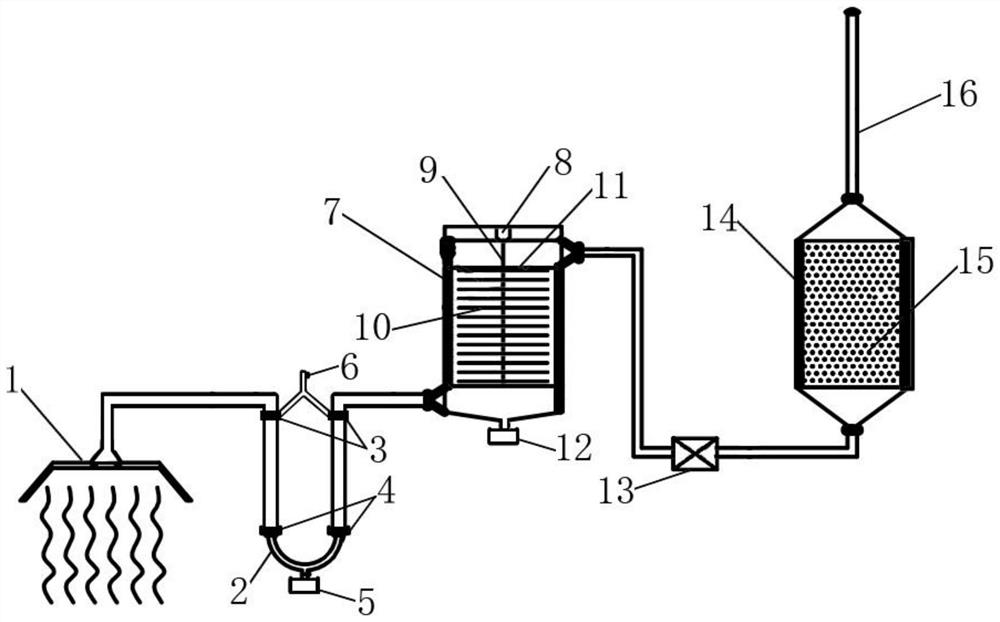

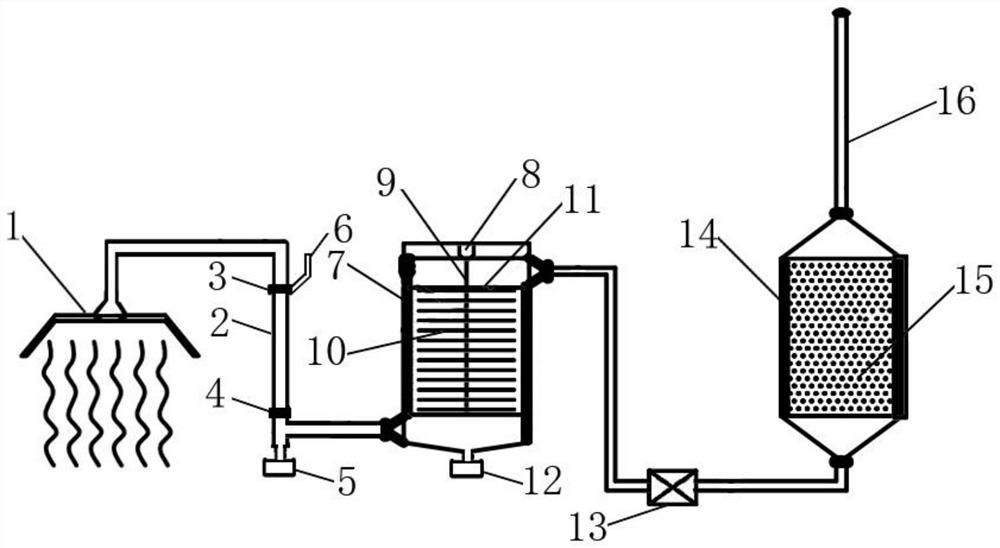

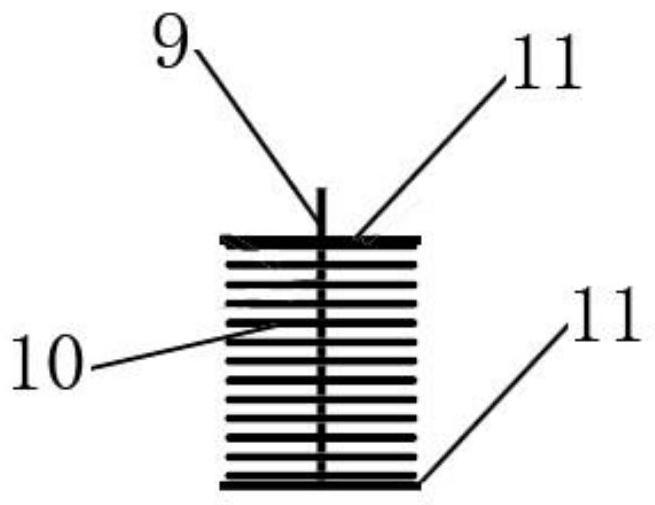

[0039] Such as figure 1 and 3 As shown, a treatment equipment for polymorphic organic compound pollutants includes...

Embodiment 2

[0059] In a barbecue restaurant, the original flue gas treatment uses an electrostatic oil fume removal system plus plasma removal of VOC, which requires a large investment, high operating costs, and insufficient processing capacity. When 50% of the barbecue seats are activated, the surrounding residents can still accept them. When the seats are more than 70%, the residents react strongly. In order to solve the problem of disturbing the residents, the equipment of the present invention is used to carry out the transformation of flue gas treatment; the original fume collecting hood and the front pipe are retained, the electrostatic oil fume removal system is removed, and a vertical I-shaped cooling pipe is added outdoors, and tap water is used as the cooling water source. The control valve is set on the ground. When the equipment is started, the water valve is opened to control the water flow speed. The cooling water collected in the sump is used for cleaning and sanitation.

...

Embodiment 3

[0080] A moxibustion physiotherapy shop originally used an electrostatic oil fume removal system for smoke control, which required a large investment and high operating costs, and it could not solve the smell of moxibustion. There are many kinds of liquid-solid gaseous VOCs in moxibustion smoke. The most odorous ones are eucalyptol and camphor. At the temperature of smoke treatment, camphor is in liquid state and camphor is in solid state. A large number of other VOCs are in gaseous state and have a certain smell. In order to solve the problem of disturbing the residents, the equipment of the present invention is used to carry out the transformation of flue gas treatment; the original fume collecting hood and the front pipe are kept, the electrostatic oil fume removal system is removed, and a vertical U-shaped cooling pipe is added outdoors, and tap water is used as the cooling water source. The control valve is set on the ground. When the equipment is started, the water valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com