Production method of polycarboxylic acid high-performance water reducing agent for concrete pipe pile

A technology of concrete pipe piles and production methods, which is applied in the direction of chemical instruments and methods, reagents, products, etc., can solve the problems of pressure increase, poor control of reaction temperature, explosion, etc., achieve pressure reduction, prevent continuous temperature rise, The effect of maintaining the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

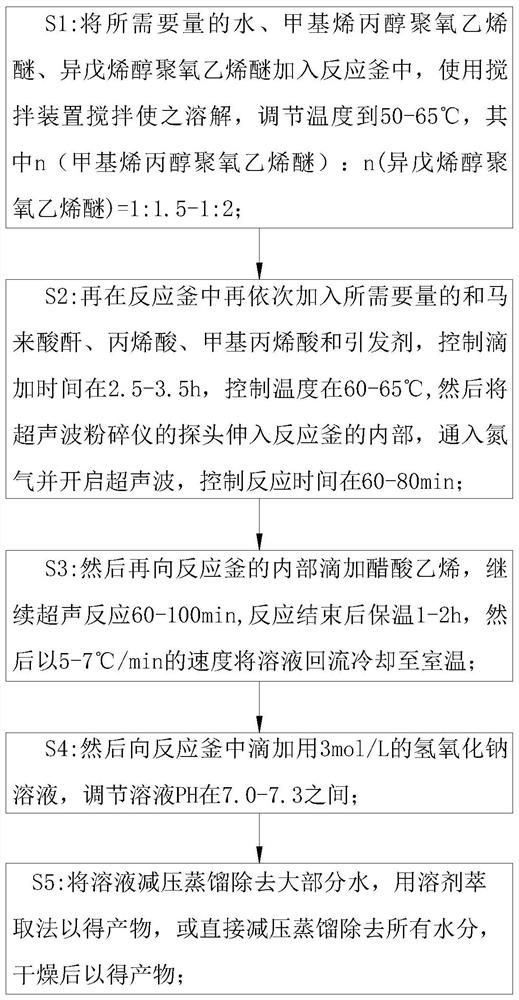

Method used

Image

Examples

Embodiment approach

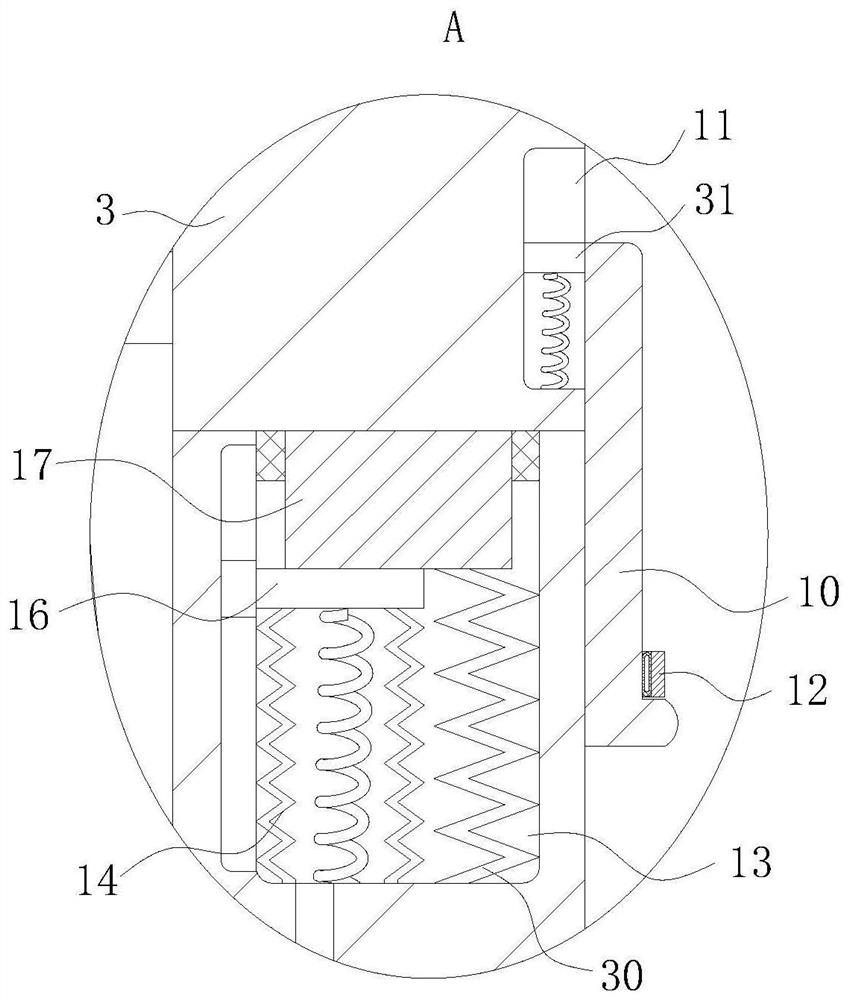

[0041] As an embodiment of the present invention, the outer wall edge of the threaded connection pipe 15 is fixedly provided with a driving ring 21; the driving ring 21 protrudes from the outer edge of the liquid feeding pipe 4, and the outer edge of the driving ring 21 is of rough design ; During work, the threaded connection pipe 15 can be rotated by the drive ring 21, and the surface of the drive ring 21 is designed to be rough, so that the rotation of the threaded connection pipe 15 is more labor-saving.

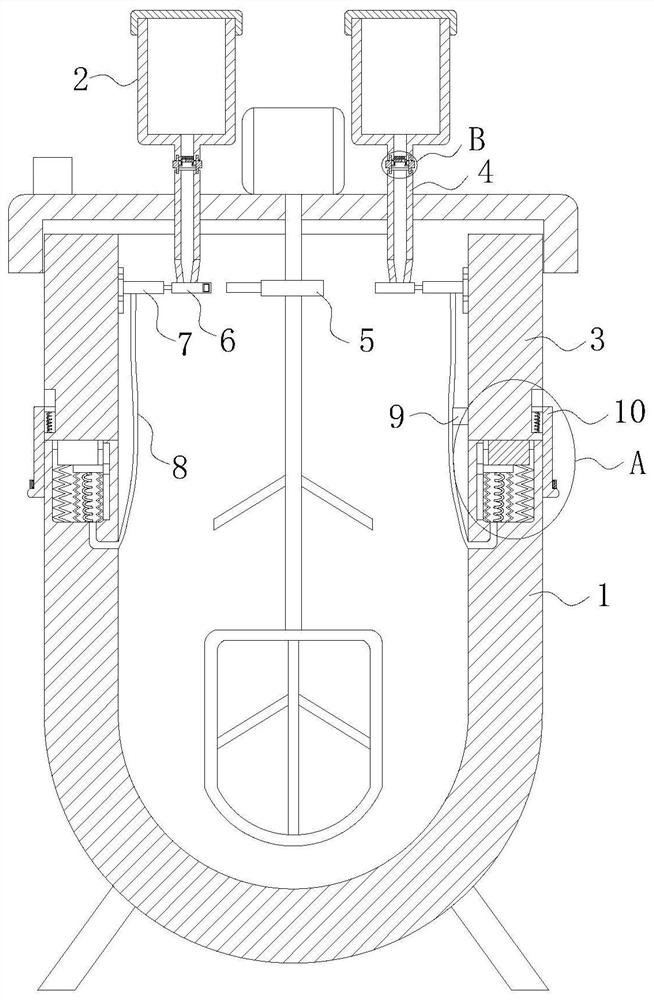

[0042]As an embodiment of the present invention, the bottom of the movable support plate 16 is located on the periphery of the spring and is fixed with a first spring compression tube 14; One end of the hollow rotating rod 7 close to the inner wall of the last kettle body 3 is fixedly connected with the surface of the piston plate 22 by a spring; the surface of the piston plate 22 away from the upper kettle body 3 is fixedly connected with an end of the contraction rod 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com