Coal dust cleaning system with combined action of mechanical grinding and ultrasonic waves and working method thereof

A mechanical grinding and co-action technology, applied in grain processing, earth cube drilling, wellbore/well components, etc., can solve the problems that cannot meet the actual needs of coalbed methane mining, less research on drainage technology and equipment, and increase work flow, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

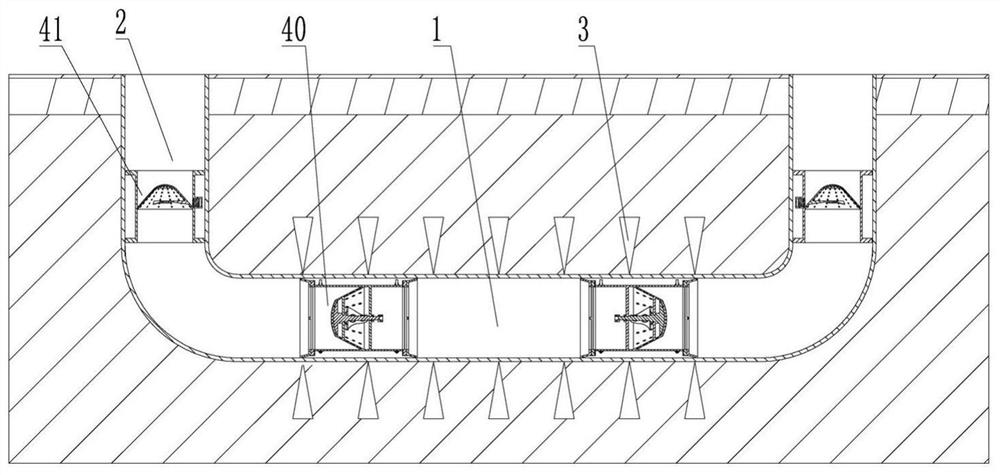

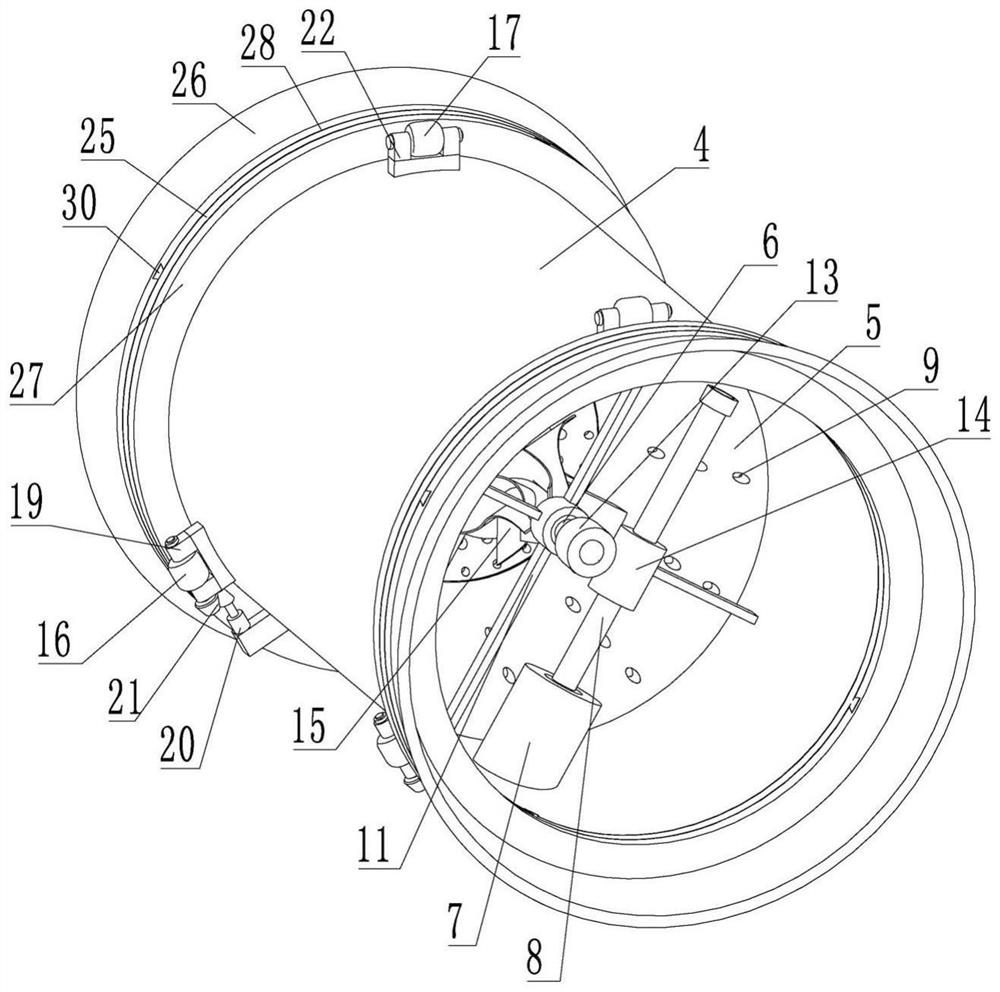

[0033] Such as Figure 1-Figure 10 As shown, the coal debris cleaning system with the combined action of mechanical grinding and ultrasonic waves includes two mechanical crushing devices 40 and two ultrasonic crushing devices 41. The two mechanical crushing devices 40 have the same structure and are symmetrically arranged in the horizontal well of the U-shaped production well. On the left and right sides of section 1, two ultrasonic crushing devices 41 have the same structure and are arranged symmetrically in the left and right vertical well sections 2 of the U-shaped production well. The middle inner wall of the horizontal well section 1 is evenly equipped with The drainage gap 3.

[0034] The mechanical crushing device 40 on the left side includes a first crushing cylinder 4, a first crushing bin 5, a crushing grinding rod 6, a crushing reduction moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com