Storage battery busbar welding quality detection equipment

A technology for welding quality and testing equipment, applied in the field of testing, can solve the problems of inability to guarantee the welding quality of busbars, the existence of missed inspections, and high costs, and achieve the effects of reducing labor intensity of workers, reducing testing costs, and eliminating missed inspections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Aiming at the through-wall welding quality inspection process of multi-variety and small-batch storage battery production lines, the invention proposes a full-automatic online inspection device that does not require manual destructive sampling inspection or replacement of tooling and fixtures. This equipment replaces the manual quality inspection of through-wall welding, realizes the automatic and online inspection of all products, and makes up for the disadvantages of random inspection; the invention is easy to operate, reduces the labor intensity of workers, and has strong applicability, and can complete 1× 6. 2×3, 1×12 and other batteries of various specifications and sizes; the equipment has high detection accuracy, can ensure the quality of batteries, and can eliminate potential safety hazards, improve work efficiency, and reduce production costs.

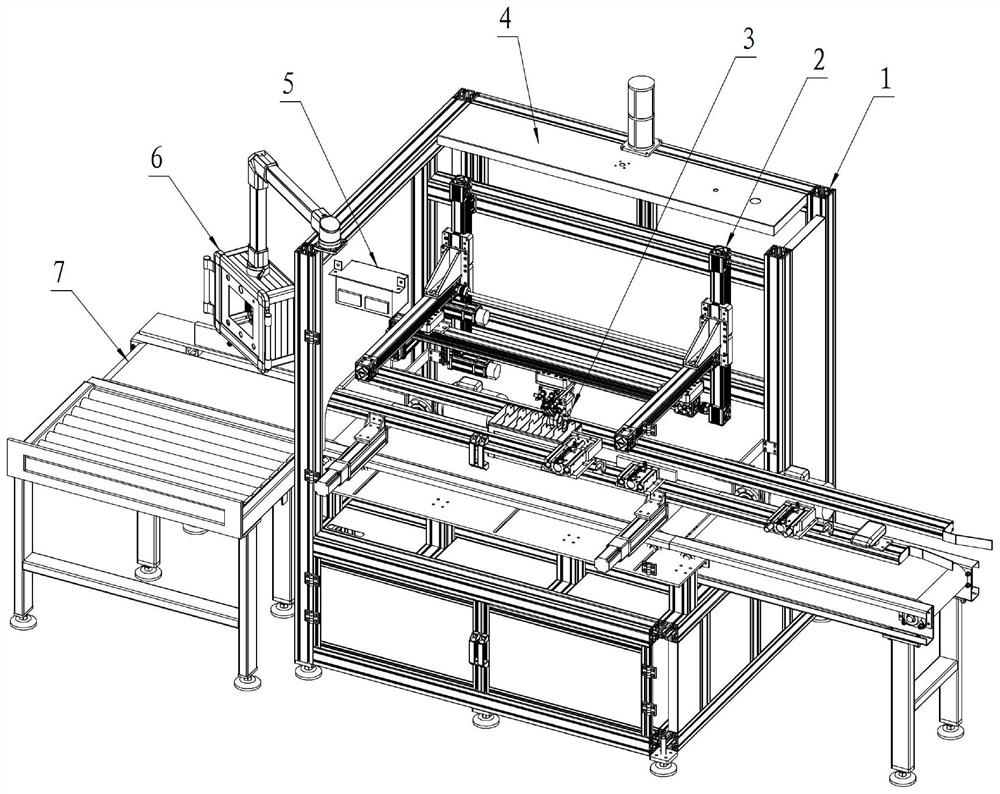

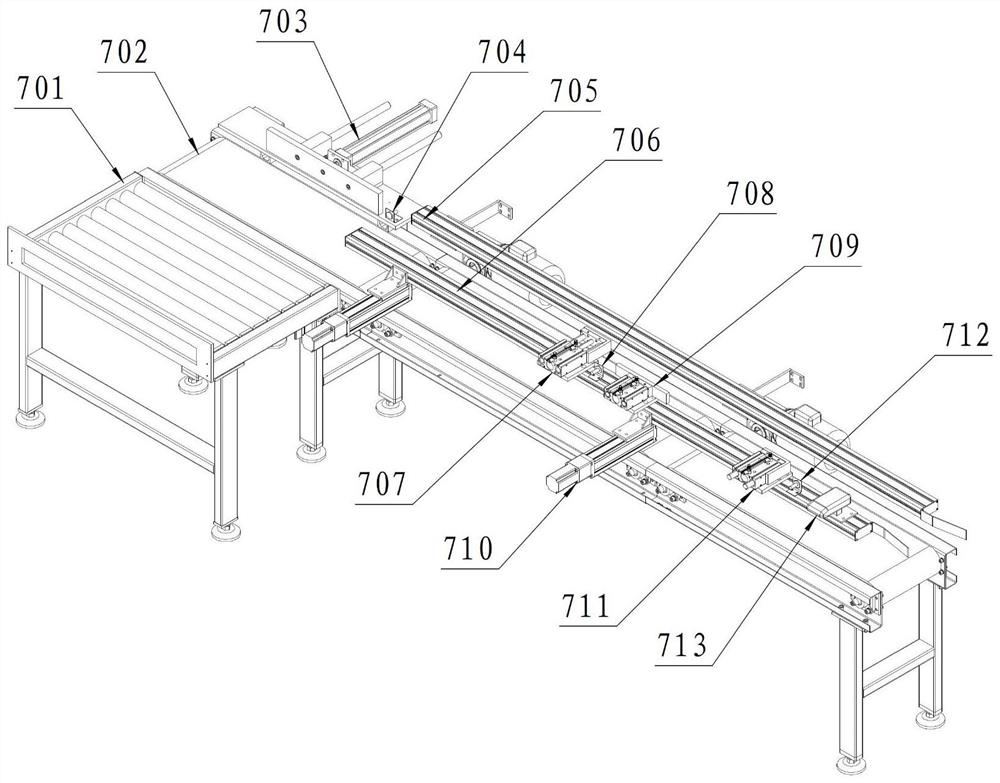

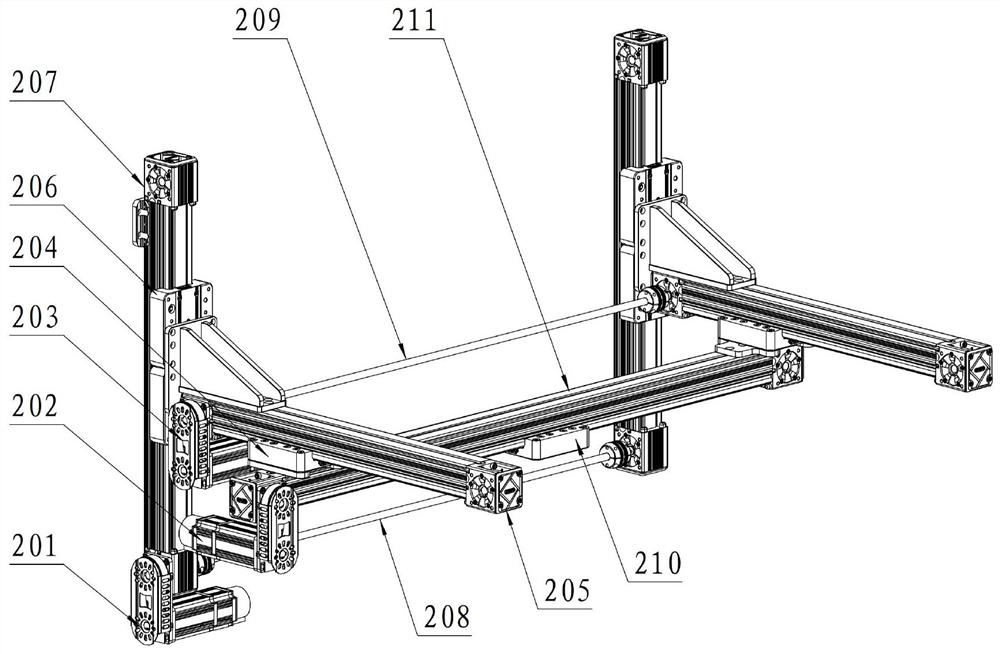

[0024] see figure 1 , the present invention includes an equipment frame 1, a three-dimensional detection position adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com