Tooth shoveling radiator and preparation method thereof

A radiator and shovel tooth technology, applied in the field of shovel tooth radiator and its preparation, can solve the problems of easy sliding of tooth holes, broken taps, abnormal quality of shovel teeth, inability to strengthen alloys, etc., so as to improve the manufacturing qualification rate and improve cutting. performance, the effect of shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

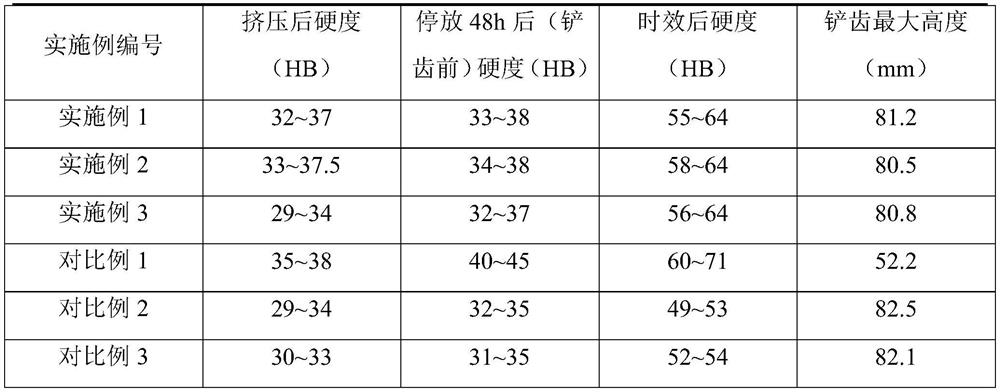

Examples

Embodiment 1

[0032] A preparation method of the shoveling tooth radiator of this embodiment. Extrusion of 6 series new alloys is carried out on aluminum alloy special-shaped extrusion plates with specifications of 229mm×25mm. The hardness before aging meets the same shoveling tooth requirements of 1060 aluminum alloy. , the hardness meets the process requirements of the anti-sticking knife for machining the bottom plate and the thread-free hole reducing nut. Concrete preparation process is as follows:

[0033] 1) Melting:

[0034] Heat the raw material aluminum ingot (purity 99.70%) to 735°C to melt to obtain molten aluminum, remove scum on the surface of molten aluminum, according to chemical composition: Si 0.28%, Mg 0.35%, Cu0.02%, Fe 0.12%, Mn 0.02% , Cr 0.02%, Zn 0.005%, Ti 0.05%, and the balance is the standard of Al to adjust the content of alloying elements in the aluminum liquid, and refining and standing; the aluminum liquid after standing is filtered, and then carried out at a ...

Embodiment 2

[0047] A preparation method of the shoveling tooth radiator of this embodiment. Extrusion of 6 series new alloys is carried out on aluminum alloy special-shaped extrusion plates with specifications of 229mm×25mm. The hardness before aging meets the same shoveling tooth requirements of 1060 aluminum alloy. , the hardness meets the process requirements of the anti-sticking knife for machining the bottom plate and the thread-free hole reducing nut. Concrete preparation process is as follows:

[0048] 1) Melting:

[0049] Heat the raw material aluminum ingot (99.70% purity) to 735°C to melt to obtain molten aluminum, remove the scum on the surface of the molten aluminum, according to the chemical composition: Si 0.25%, Mg 0.41%, Cu0.02%, Fe 0.11%, Mn 0.02% , Cr 0.02%, Zn 0.005%, Ti 0.05%, and the balance is the standard of Al to adjust the content of alloying elements in the aluminum liquid, and refining, standing still; the aluminum liquid after standing is filtered, and then ca...

Embodiment 3

[0061] A preparation method of the shoveling tooth radiator of this embodiment. Extrusion of 6 series new alloys is carried out on aluminum alloy special-shaped extrusion plates with specifications of 229mm×25mm. The hardness before aging meets the same shoveling tooth requirements of 1060 aluminum alloy. , the hardness meets the process requirements of the anti-sticking knife for machining the bottom plate and the thread-free hole reducing nut. Concrete preparation process is as follows:

[0062] 1) Melting:

[0063] Heat the raw material aluminum ingot (99.70% purity) to 735°C to melt to obtain molten aluminum, remove the scum on the surface of the molten aluminum, according to the chemical composition: Si 0.25%, Mg 0.41%, Cu0.02%, Fe 0.11%, Mn 0.02% , Cr 0.02%, Zn 0.005%, Ti 0.05%, and the balance is the standard of Al to adjust the content of alloying elements in the aluminum liquid, and refining, standing still; the aluminum liquid after standing is filtered, and then ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com