File plastic packaging machine with electric telescopic rods

An electric telescopic rod and packaging machine technology, which is applied in the field of packaging equipment, can solve the problems of inability to scan and save file contents, easy entry of air into the plastic packaging of documents, and inability to automatically classify and package, so as to shorten replacement time, facilitate packaging, and improve packaging quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

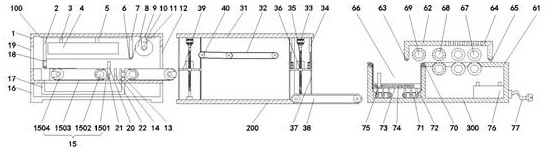

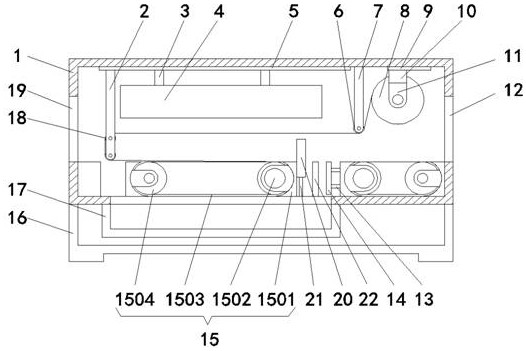

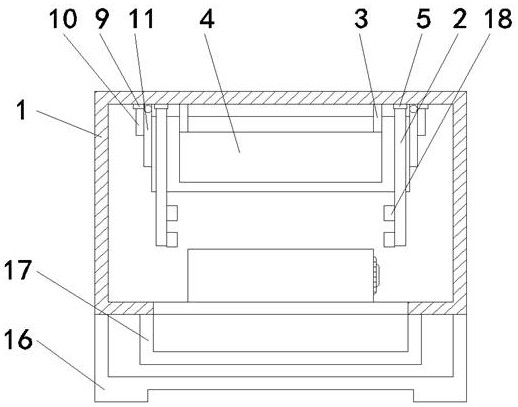

[0051] Embodiment of the present invention provides a telescopic rod having an electric file plastic packaging machine, aimed at solving the current file plastic packaging machine with electric retractable rod shrink films can not be aligned, not classified according to the number of pages automatically packaging, not the file content scanning on file, and easy access to air, prone to wrinkles plastic molding and so on down a file.

[0052] By fixing bar disposed within the housing means for the film, and the slider clamp block, by mounting a shrink film, the shrink film is subjected to stretching and fixing bar slider form a bilayer membrane structure, which can solve the two films the problem can not be aligned, so that the speed of the plastic also been improved, and the effect of reinforcing the plastic.

[0053] A first drive motor driven by rotation of the first threaded rod transfer mechanism, so as to drive down the suspension, file placed in the automatic transmission eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com