Graphite electrode device for preparing graphene by stripping graphite through electrochemical method

A technology for exfoliating graphite and graphite electrodes, applied in the field of graphene, can solve the problems of graphite sheet structure damage, line fuse, small scale, etc., and achieve the effects of avoiding serious heat generation, avoiding short circuits, and large contact surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

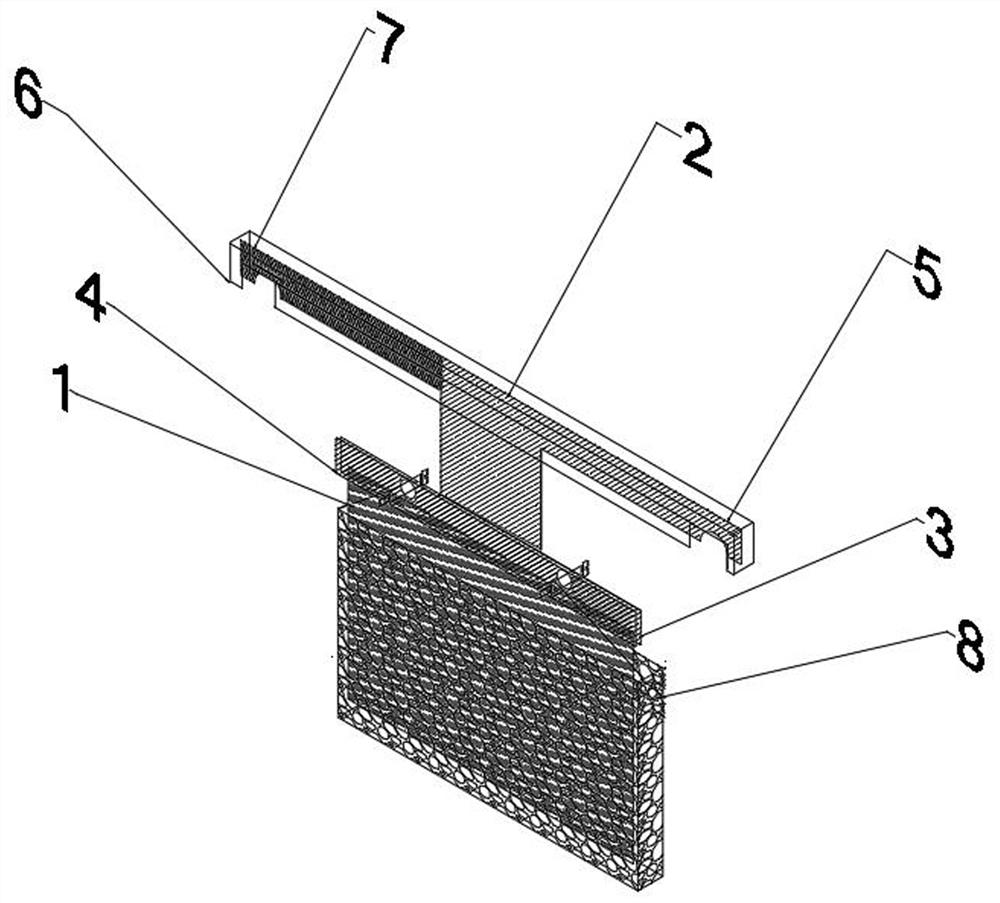

[0017] refer to figure 1 , a graphite electrode device for electrochemically exfoliating graphite to prepare graphene, comprising a graphite 1 and a conductive fixture 2, the conductive fixture 2 is provided with a first metal clip 3 and a second metal clip 4, the graphite 1 The edge is sandwiched between the first metal clip 3 and the second metal clip 4, the connection method is metal-graphite-metal, and the contact surface is fixed with fasteners, wherein the first metal clip 3 covers the edge of the graphite 1 One side of the part extends outward to form a strip-shaped conductive ear 5, and the conductive ear 5 is sandwiched by an insulating plate 6. The insulating plate 6 and the conductive ear 5 are in the shape of a mirror-symmetrical part and the shape of the symmetrical part of the conductive ear 5. The shape is the same as the insulating tab 7, and the outward ends of the conductive tab 5 and the insulating tab 7 are provided with a semicircular hole with the same ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com