Flexible film-like material for SERS detection and preparation method of flexible film-like material

A technology for detecting flexible and flexible films, which is applied in the fields of analyzing materials, material excitation analysis, and material analysis by optical means. Uniform thickness, easy to wipe sampling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

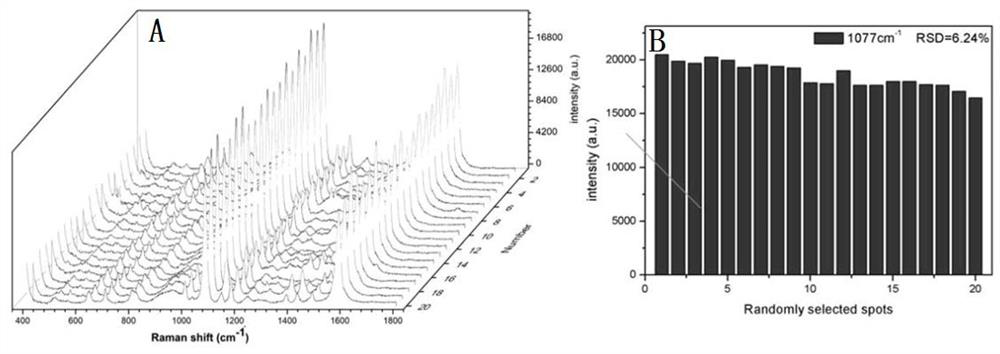

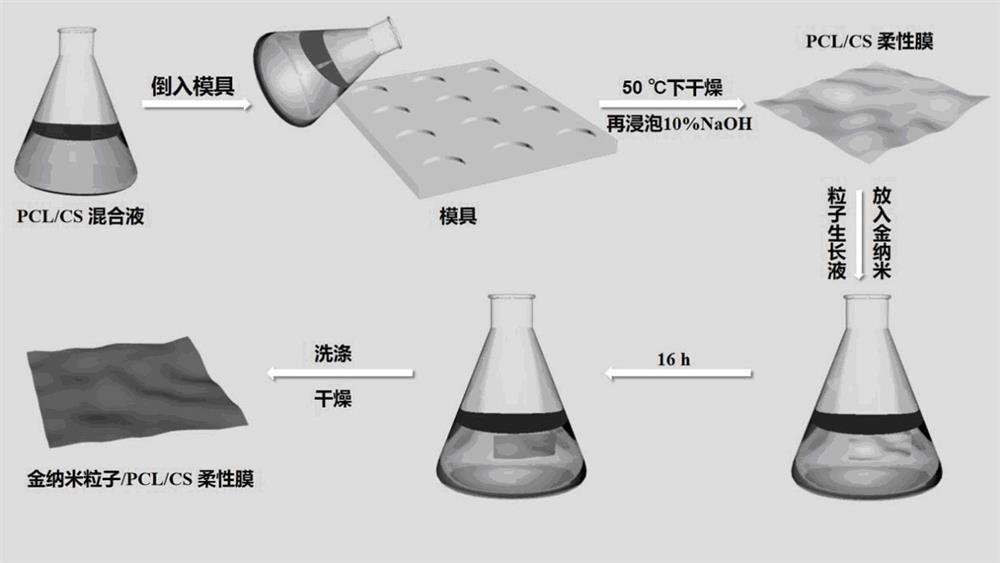

[0029] Embodiment 1 (see figure 1 )

[0030] 1) Preparation of PCL / CS composite solution: Dissolve 0.8g of PCL particles in 9.2g of glacial acetic acid solution at 50°C to obtain 8%wt PCL solution; dissolve 0.2g of CS powder in 9.8g of 90%wt acetic acid at 90°C solution, a 2% wt CS solution was obtained. At 50°C, 3.33g 8%wt PCL was added dropwise to 10g 2%wt CS with a mass ratio of 1:1.5, and stirred at 50°C for 2h to synthesize a PCL / CS solution.

[0031] 2) Preparation of PCL / CS flexible film: inject the PCL / CS solution into the mold, dry it at 50°C to form a film, soak it in 10% NaOH for 5 minutes, rinse and soak it with clean water until the solution is neutral. Finally, dry again in a natural state for later use.

[0032] 3) Preparation of gold seed solution: 0.025mL 0.01M HAuCl 4 solution and 0.6 mL of 0.01M NaBH 4 The solution was added to 1 mL of 0.1M CTAB solution, stirred for 30 min, and left to stand for use.

[0033] 4) Immerse the PCL / CS flexible film cut in...

Embodiment 2

[0037]1) Preparation of PCL / CS composite solution: Dissolve 0.8g of PCL particles in 9.2g of glacial acetic acid solution at 50°C to obtain 8%wt PCL solution; dissolve 0.2g of CS powder in 9.8g of 90%wt acetic acid at 90°C solution, a 2% wt CS solution was obtained. At 50°C, 3.33g 8%wt PCL was added dropwise to 10g 2%wt CS with a mass ratio of 1:1.5, and stirred at 50°C for 2h to synthesize a PCL / CS solution.

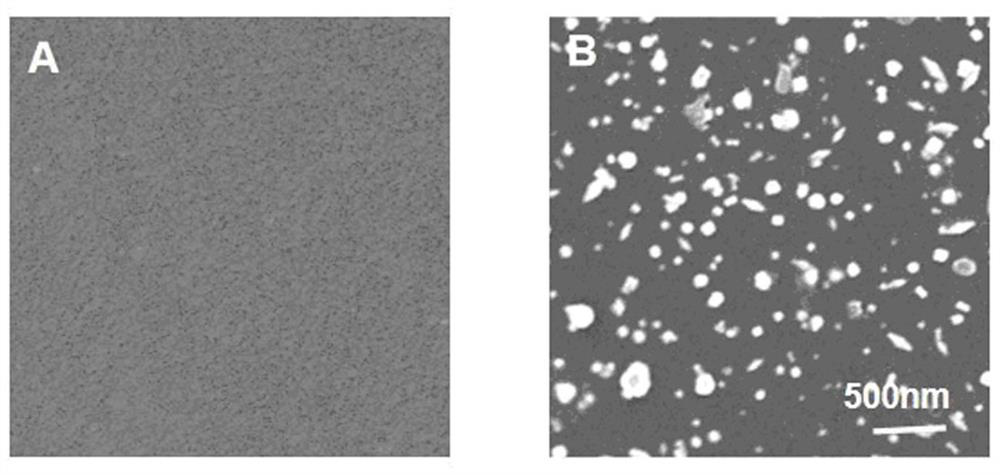

[0038] 2) Preparation of PCL / CS flexible film: inject the PCL / CS solution into the mold, dry it at 50°C to form a film, soak it in 10% NaOH for 5 minutes, rinse and soak it with clean water until the solution is neutral. Finally, it was dried again in a natural state for further use, and its morphology was characterized by SEM.

[0039] 3) Preparation of gold seed solution: 0.025mL 0.01M HAuCl 4 solution and 0.6 mL of 0.01M NaBH 4 The solution was added to 1 mL of 0.1M CTAB solution, stirred for 30 min, and left to stand for use.

[0040] 4) Immerse the PCL / CS flexi...

Embodiment 3

[0044] 1) Preparation of PCL / CS composite solution: Dissolve 0.8g of PCL particles in 9.2g of glacial acetic acid solution at 50°C to obtain 8%wt PCL solution; dissolve 0.2g of CS powder in 9.8g of 90%wt acetic acid at 90°C solution, a 2% wt CS solution was obtained. At 50°C, 3.33g 8%wt PCL was added dropwise to 10g 2%wt CS with a mass ratio of 1:1.5, and stirred at 50°C for 2h to synthesize a PCL / CS solution.

[0045] 2) Preparation of PCL / CS flexible film: inject the PCL / CS solution into the mold, dry it at 50°C to form a film, soak it in 10% NaOH for 5 minutes, rinse and soak it with clean water until the solution is neutral. Finally, dry again in a natural state for later use.

[0046] 3) Preparation of gold seed solution: 0.025mL 0.01M HAuCl 4 solution and 0.6 mL of 0.01M NaBH 4 The solution was added to 1 mL of 0.1M CTAB solution, stirred for 30 min, and left to stand for use.

[0047] 4) Immerse the PCL / CS flexible film cut into a suitable size into the gold nanopar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com