Graphene composite base material and graphene two-dimensional floor prepared from base material

A graphene composite and graphene technology, which is applied in construction, building structure, floor, etc., can solve the problems of heavy floor quality, poor thermal conductivity, and poor stability, and achieve long service life, good thermal conductivity, and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

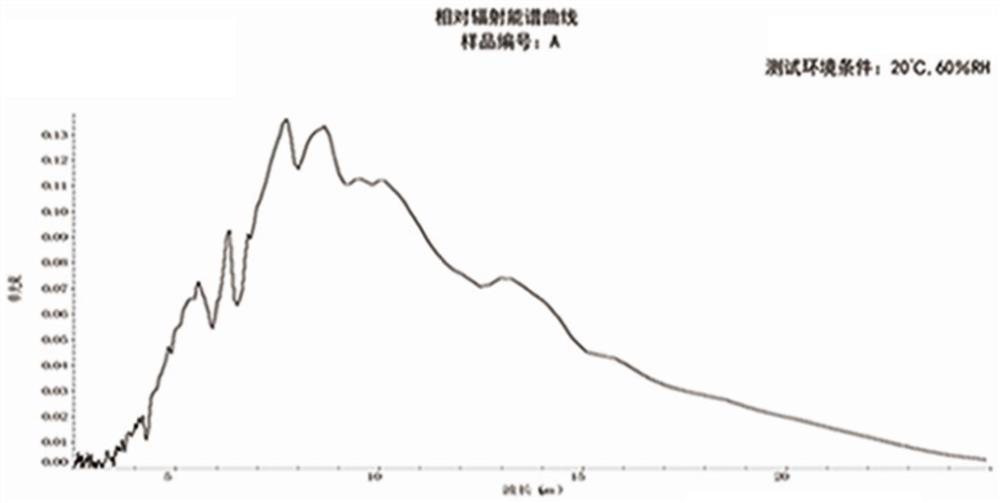

Image

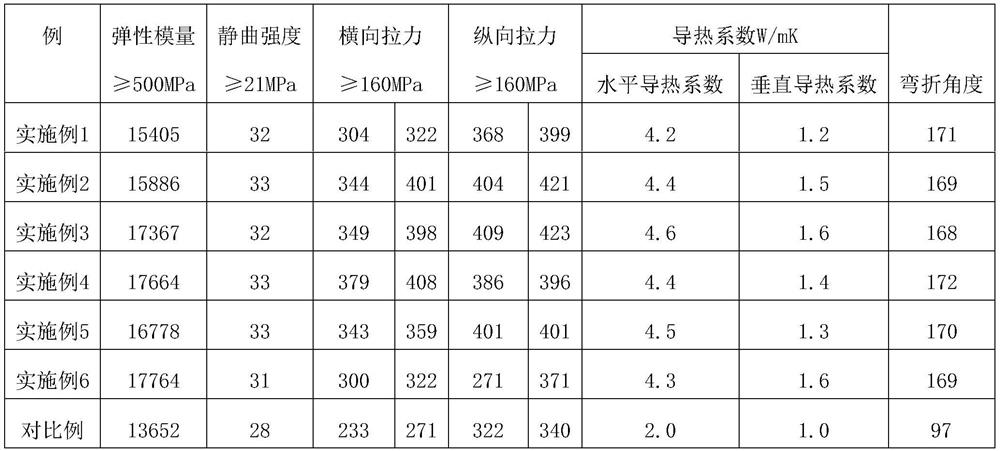

Examples

preparation example Construction

[0022] The present invention also provides a preparation method of a graphene composite base material, comprising: mixing graphene, crystalline calcium carbonate, polyvinyl chloride, calcium-zinc composite stabilizer, hard Fatty acid, polyethylene wax, acrylate polymer and chlorinated polyethylene to obtain a mixture; the mixture is heated through seven temperature control zones in sequence, and the seven temperature control zones are respectively: the first zone 180-210°C, The second zone is 175-205°C, the third zone is 160-190°C, the fourth zone is 175-190°C, the fifth zone is 160-190°C, the sixth zone is 180-210°C, the seventh zone is 200-240°C; The final mixture is shaped into a sheet by a mold, and pressed by a thickness-controlled pressure roller to obtain a graphene composite substrate with a thickness of 2.5-6.0 mm.

[0023] The present invention also provides a graphene two-dimensional floor, comprising the above-mentioned graphene composite substrate layer, a color f...

Embodiment 1

[0028] The raw materials of the graphene composite substrate layer include: 3.5 parts of graphene, 80 parts of crystalline calcium carbonate, 40 parts of polyvinyl chloride, 6 parts of calcium-zinc composite stabilizer, 0.7 part of stearic acid, 0.6 part of polyethylene wax, acrylates 4 parts of polymer, 4 parts of chlorinated polyethylene. The above raw materials are mixed and heated through seven temperature control zones. The temperatures of the seven temperature control zones are as follows: the first zone is 191°C, the second zone is 188°C, the third zone is 170°C, the fourth zone is 180°C, and the fifth zone is 180°C. Zone 175°C, Zone 6 200°C, Zone 7 230°C. The heated mixture is shaped into a sheet from a mold, and passed through a set of thickness-controlled pressure rollers to obtain a graphene microcrystalline substrate layer sheet with a thickness of 5.0 mm.

[0029] The graphene two-dimensional floor comprises the above-mentioned graphene composite substrate layer,...

Embodiment 2

[0031] The raw materials of the graphene composite substrate layer include: 3.5 parts of graphene, 220 parts of crystalline calcium carbonate, 80 parts of polyvinyl chloride, 10 parts of calcium-zinc composite stabilizer, 1.4 parts of stearic acid, 1.2 parts of polyethylene wax, acrylates 4.5 parts of polymer, 4.9 parts of chlorinated polyethylene. The above raw materials are mixed and heated through seven temperature control zones. The temperatures of the seven temperature control zones are as follows: the first zone is 191°C, the second zone is 188°C, the third zone is 170°C, the fourth zone is 180°C, and the fifth zone is 180°C. Zone 175°C, Zone 6 200°C, Zone 7 230°C. The heated mixture is shaped into a sheet from a mold, and passed through a set of thickness-controlled pressure rollers to obtain a graphene microcrystalline substrate layer sheet with a thickness of 5.0 mm.

[0032] The graphene two-dimensional floor comprises the above-mentioned graphene composite substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com