Probe for tobacco quality spectrum detection

A spectrum and tobacco leaf technology, applied in the field of infrared spectrum detection, can solve the problems of increasing the risk of contact with the liquid to be measured, the surface of the lens being exposed, and being easily collided. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

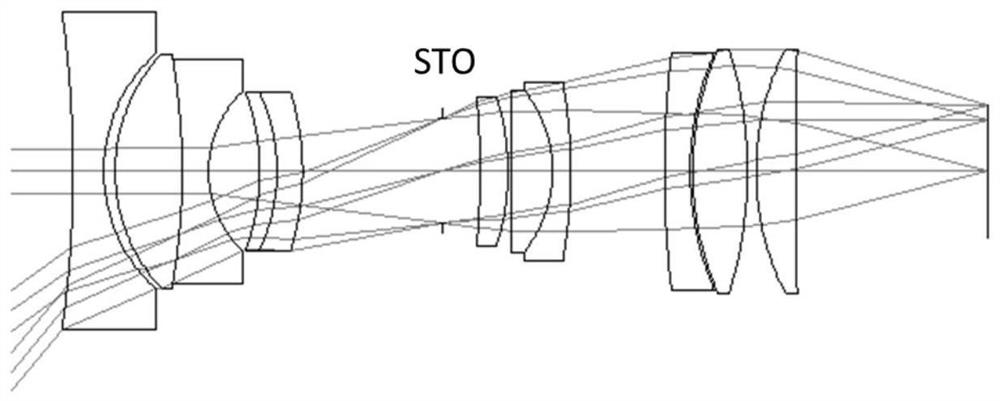

Image

Examples

Embodiment 1

[0024] The parameters of each optical lens in this embodiment are shown in Table 1.

[0025]

[0026]

[0027] Table 1

[0028] Among them, the meaning of each symbol is as follows:

[0029] S1: Entrance pupil position

[0030] R1: radius of curvature of the object side surface of the first lens L1;

[0031] R2: radius of curvature of the image side of the first lens L1;

[0032] R3: radius of curvature of the object side surface of the second lens L2;

[0033] R4: radius of curvature of the image side of the second lens L2;

[0034] R5: radius of curvature of the object side surface of the third lens L3;

[0035] R6: radius of curvature of the image side of the third lens L3;

[0036] R7: the radius of curvature of the object side of the fourth lens (cemented lens) L4;

[0037] R8: the radius of curvature of the image side of the fourth lens (cemented lens) L4;

[0038] R9: the radius of curvature of the image side of the fifth lens (cemented lens) L5;

[0039]...

Embodiment 2

[0085] The parameters of each optical lens in this embodiment are shown in Table 3.

[0086]

[0087]

[0088] table 3

[0089] The meanings of the letters used in Table 3 are the same as in Example 1.

[0090] The third lens is an aspheric lens, and its aspheric coefficients are shown in the table below:

[0091]

[0092] Table 4

[0093] In this embodiment, the first lens L1, the second lens L2, the third lens L3, the fourth lens L4, the fifth lens L5, the sixth lens L6, the seventh lens L7, The eighth lens L8, the ninth lens L9, the tenth lens L10, and the eleventh lens L11; wherein the third lens is an aspheric lens.

[0094] According to the aspherical image height formula:

[0095]

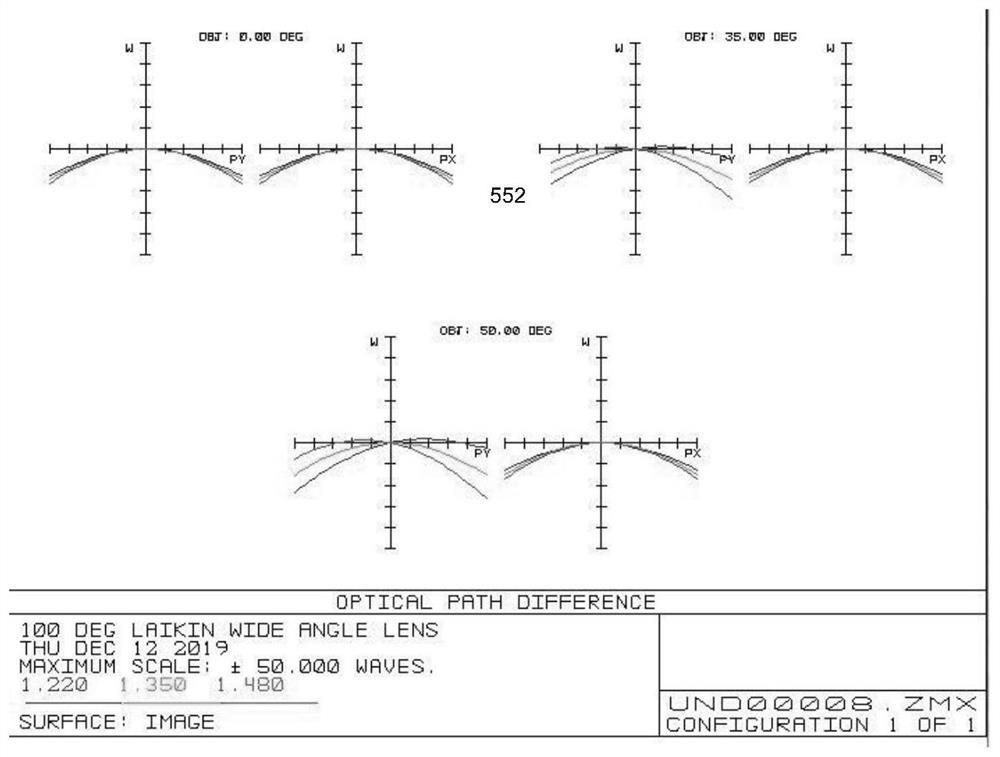

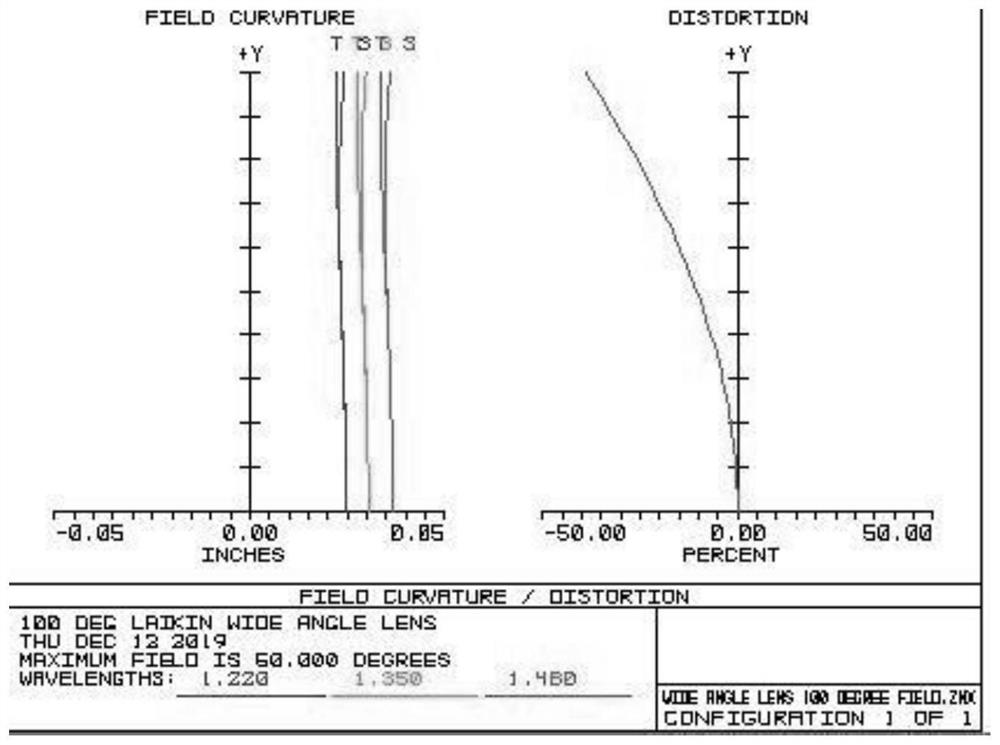

[0096] Where k is the conic coefficient, for the surface R5, K5 = 1.418; for the surface R6, K6 = 1.134. A4, A6, A8, A10, A12, A14, A16 are aspheric coefficients.

[0097] The equivalent focal length of the optical system is f=1.521cm. The object side of the first lens is ...

Embodiment 3

[0101] The parameters of each optical lens in this embodiment are shown in Table 5.

[0102]

[0103]

[0104] table 5

[0105] The third lens is an aspheric lens, and its aspheric coefficients are shown in Table 6:

[0106]

[0107] Table 6

[0108] According to the aspherical image height formula:

[0109]

[0110] Wherein k is the conic coefficient, for the surface R5, K5=1.538; for the surface R6, K6=1.170. A4, A6, A8, A10, A12, A14, A16 are aspheric coefficients.

[0111] The equivalent focal length of the optical system is f=1.473cm. The object side of the first lens is a concave surface, the focal power of the first lens is set to be negative, and its focal length f1=-1.184cm; Set the focal power of the third lens to be negative, and its focal length f3=-1.926cm, Set the distance D9=1.104cm between the aperture STO of the probe optical system and the image side of the fifth lens L5; the distance D10=0.321cm between the aperture STO and the object s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com