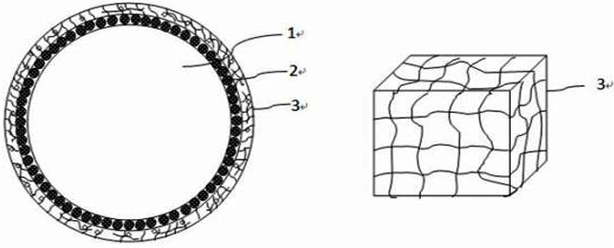

Ternary positive electrode material with dual-core shell structure and preparation method thereof

A ternary material, core-shell type technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of residual, affecting the cycle life and specific capacity of lithium-ion batteries, and producing harmful substances, so as to reduce energy consumption, Eliminates washing and drying processes and improves cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a double core-shell type ternary material, comprising the steps of:

[0045] (1) Weigh the lithium source and the ternary material precursor according to the molar ratio of Li: ternary material precursor = (1+x): 1, and weigh the oxide additive in addition, and fully mix the above materials in a high-speed mixer Mixture A is obtained after uniformity; wherein, 0.01≤x≤0.09, the oxide additive is one or more of nano-alumina, nano-titanium oxide, and nano-magnesia. In terms of mass ratio, the oxide additive / mixture A =0.1~0.5%;

[0046] (2) The mixture A is roasted, the roasting atmosphere is an inert atmosphere or an oxygen-containing atmosphere, the roasting temperature is 700 ° C to 950 ° C, the roasting time is 10 to 20 hours, after the roasting is completed, cool for 4 to 12 hours, then pulverize and sieve The semi-finished product B is obtained, and the particle size of the semi-finished product B is 8-13 μm;

[0047] (3) Stir the semi-finish...

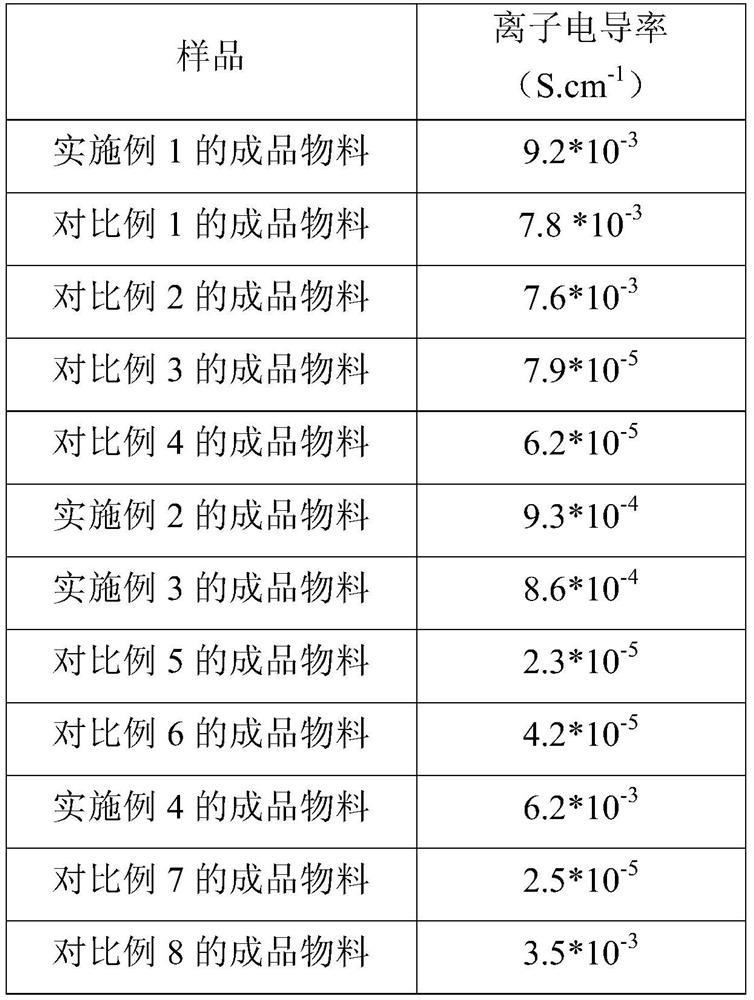

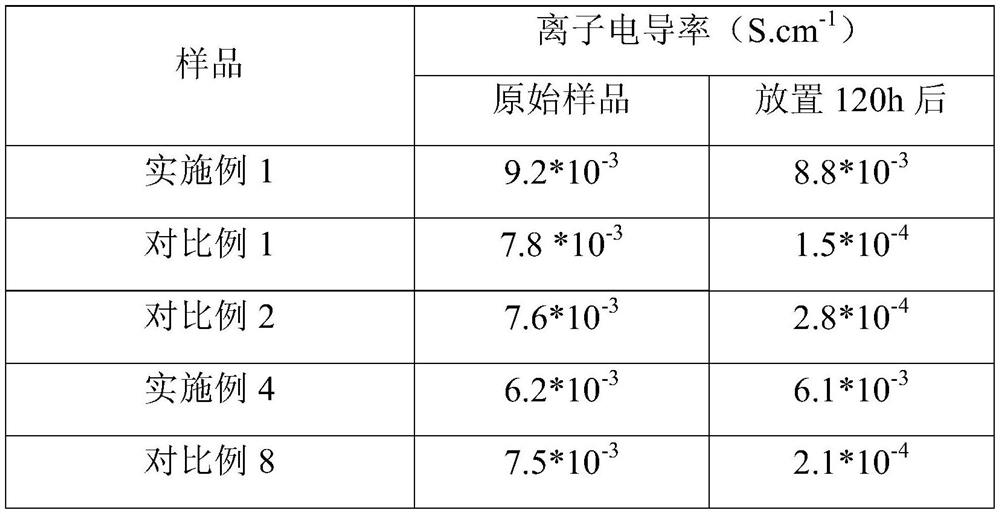

Embodiment 1

[0061] A method for preparing a double core-shell type ternary material, comprising the steps of:

[0062] (1) Weigh lithium hydroxide and ternary material precursor (Ni 0.8 co 0.2 mn 0.2 )(OH) 2 In addition, according to the mass ratio of 1:2, the mixture of nano-alumina and nano-magnesia is weighed as an additive, and the above-mentioned materials are fully mixed in a high-speed mixer to obtain a mixture A; wherein, x=0.05, and the mass of the additive accounts for the weight of the mixture. The mass ratio of A is 0.2%;

[0063] (2) The mixture A is roasted, the roasting atmosphere is an oxygen-containing atmosphere, the roasting temperature is 750°C, and the roasting time is 15 hours. After the roasting is completed, it is cooled for 8 hours and then pulverized and sieved to obtain the semi-finished product B. The particle size of the semi-finished product B is 12μm;

[0064] (3) Stir and mix the semi-finished product B and the iron-aluminum phosphate according to a ce...

Embodiment 2

[0091] A method for preparing a double core-shell type ternary material, comprising the steps of:

[0092] (1) Take Lithium Carbonate and (Ni 0.5 co 0.3 mn 0.2 )(OH) 2 , In addition, aluminum oxide is weighed as an additive, and the above-mentioned materials are fully mixed in a high-speed mixer to obtain a mixture A; wherein in terms of mass ratio, the oxide additive / mixture A=0.1%;

[0093] (2) The mixture A is roasted, the roasting atmosphere is an inert atmosphere or an oxygen-containing atmosphere, the roasting temperature is 700° C., and the roasting time is 10 hours. After the roasting is completed, it is cooled for 4 hours and then pulverized and sieved to obtain the semi-finished product B. The semi-finished product The particle size of B is 8 μm;

[0094] (3) Stir and mix the semi-finished product B and aluminum trifluoromethanesulfonate according to a certain ratio to obtain a mixture C; wherein, in terms of mass ratio, aluminum trifluoromethanesulfonate / mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com