Preparation method of platinum-cobalt alloy nano electrocatalyst

A nano-catalyst, platinum-cobalt alloy technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as slow instability, oxygen reduction capacity limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of preparation method of high-performance 52% platinum-cobalt alloy nano electrocatalyst, its steps are as follows:

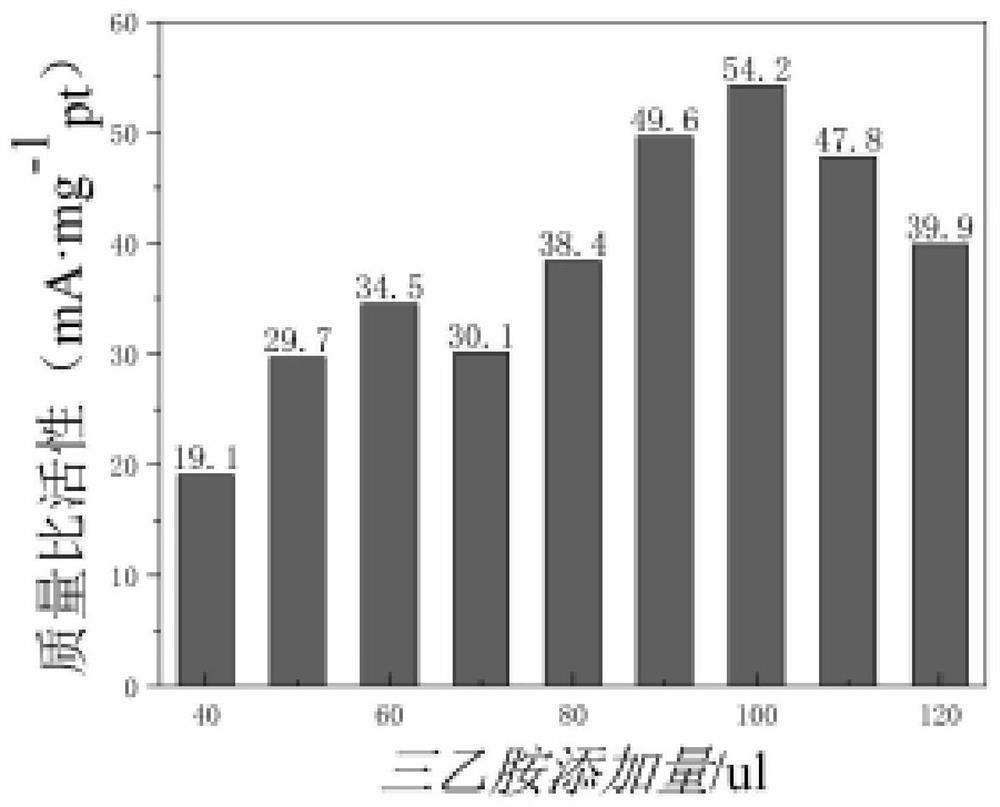

[0020] Step 1, take by weighing 1.504g chloroplatinic acid aqueous solution (H 2 PtCl 6 ·6H 2 O, the mass fraction is 10%), 21.78mg cobalt chloride (CoCl 2 ·6H 2 0), triethylamine 100ul is added 25mL ethanol to dissolve, and it is placed in supersonic wave ultrasonic 30min to make mixed solution, for subsequent use;

[0021] Step 2. Weigh 57.84 mg of carbon black ECP-600 and add it to absolute ethanol, mix well, and ultrasonicate for 1 hour to obtain carbon black slurry;

[0022] Step 3, adding the mixed solution of Step 1 to the carbon black slurry of Step 2, and ultrasonically uniformly obtaining the precursor solution;

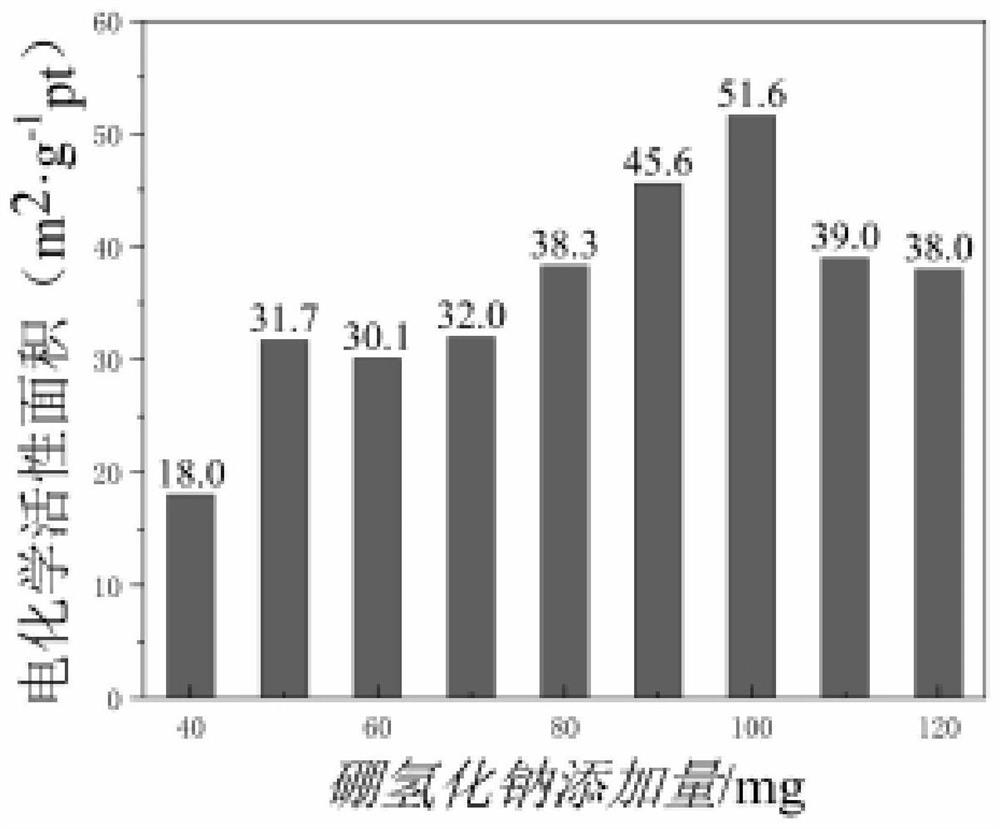

[0023] Step 4: Weigh 100 mg of sodium borohydride and dissolve it in 5 ml of ethanol, pour it into the precursor solution, and continue to stir and react for 1 hour at 1000 rpm; filter, wash, and dry to obtain a high-perfo...

Embodiment 2

[0026] A kind of preparation method of high-performance 52% platinum-cobalt alloy nano electrocatalyst, its steps are as follows: step 1, take by weighing 1.504g chloroplatinic acid aqueous solution (H 2 PtCl 6 ·6H 2 O, the mass fraction is 10%), 21.78mg cobalt chloride (CoCl 2 ·6H 2 0), triethylamine 100ul is added 25mL ethanol to dissolve, and it is placed in supersonic wave ultrasonic 30min to make mixed solution, for subsequent use;

[0027] Step 2. Weigh 57.84 mg of carbon black ECP-600 and add it to absolute ethanol, mix well, and ultrasonicate for 1 hour to obtain carbon black slurry;

[0028] Step 3, adding the mixed solution of Step 1 to the carbon black slurry of Step 2, and ultrasonically uniformly obtaining the precursor solution;

[0029] Step 4: Weigh 100 mg of sodium borohydride and dissolve it in 5 ml of ethanol, pour it into the precursor solution, and continue to stir and react for 1 hour at 1000 rpm; filter, wash, and dry to obtain a high-performance pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com