Preparation method of PdCu alloy particle loaded NiFe-LDH metal nanosheet material electrocatalyst

A technology of metal nano and alloy particles, which is applied in the direction of electrodes, circuits, electrolytic components, etc., and can solve problems such as threats to the environment and human health, and polluted water sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

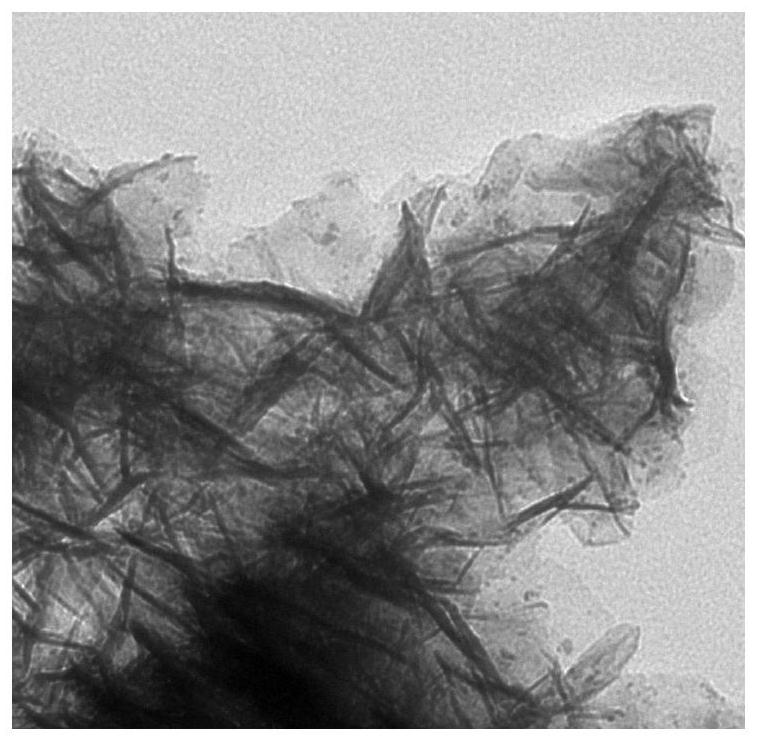

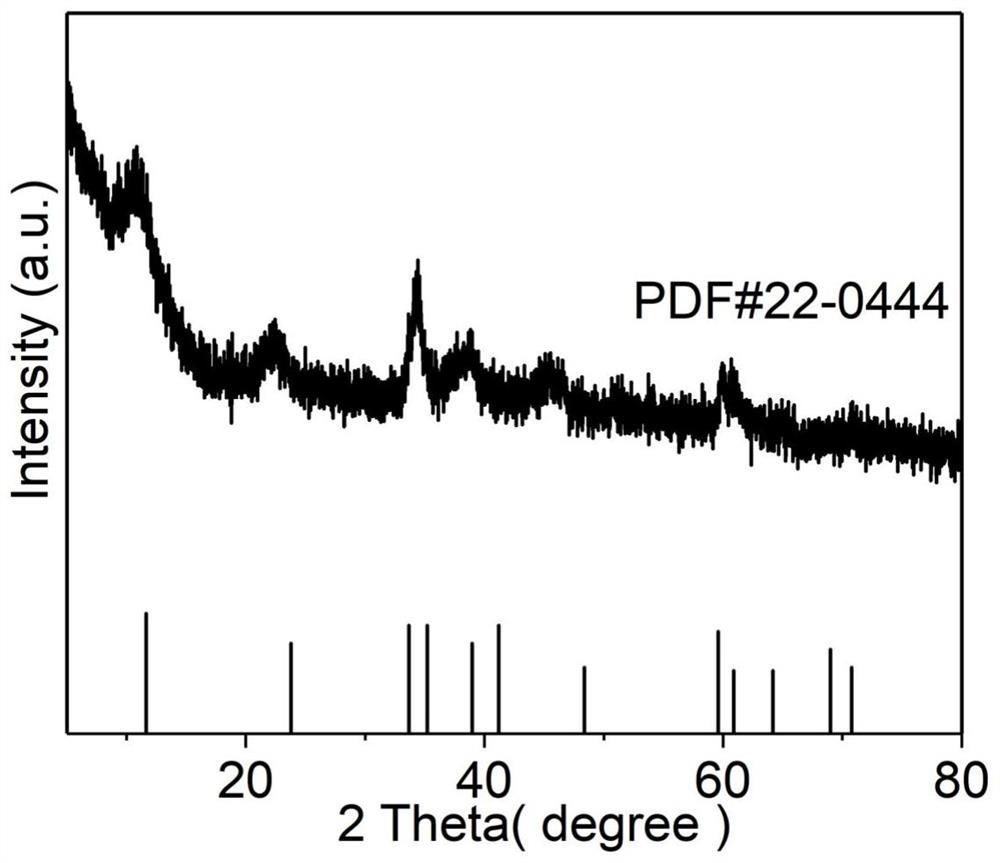

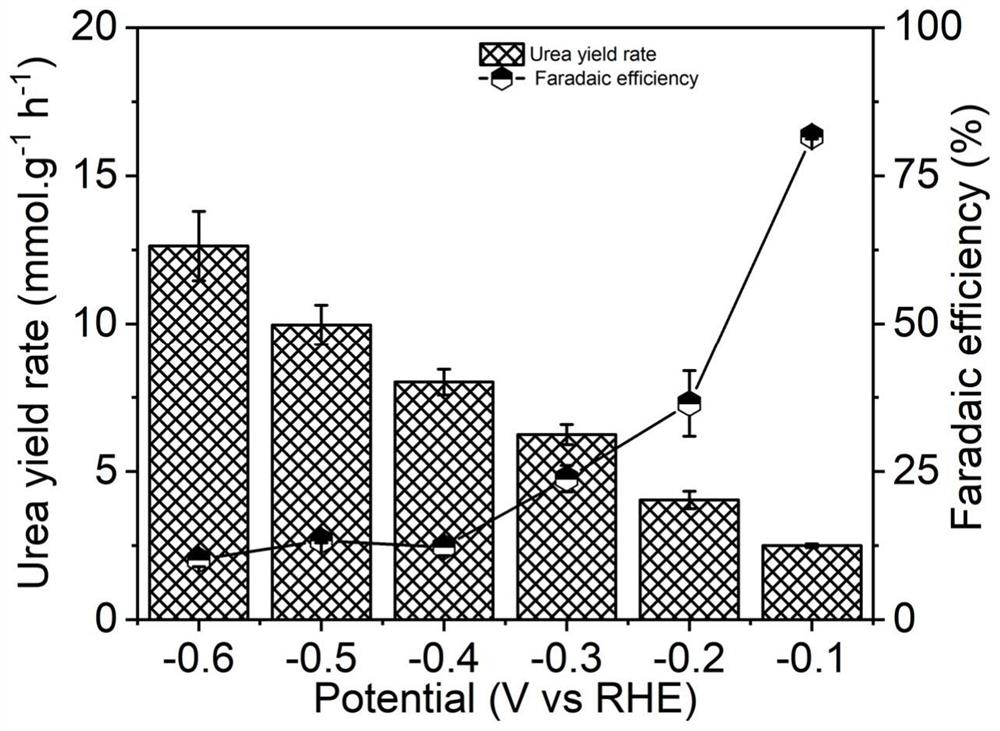

Image

Examples

Embodiment 1

[0022] Step (1) mix 0.25 liters of deionized water and 0.75 liters of triethylene glycol, first add 25g nickel nitrate hexahydrate, add 8g ferric chloride hexahydrate after dissolving, add 20g urea after ultrasonic dispersion for 15 minutes, and stir for 1.5 hours , to form a uniform reaction solution;

[0023] Step (2) The reaction solution is placed in a hydrothermal kettle for heating reaction, the heating temperature is 110 ° C, and the heating time is 30 hours; after the reaction is completed, filter and wash with deionized water 3 times, put it into the ethanol solution and soak for 20 hours, Washed with absolute ethanol twice, dried in a vacuum oven at 50°C for 30 hours to obtain NiFe-LDH powder;

[0024] Step (3) Dissolve 2 grams of NiFe-LDH powder in 1 liter of deionized water, and then add 0.1 grams of K 2 PdCl 4 and 0.01 g CuCl 2 .2H 2 O, fully dissolved; take NaBH with a concentration of 1 mmol / L 4 Add 1 liter of solution in 10 times, 100 ml each time, and sti...

Embodiment 2

[0028] Step (1) Mix 0.2 liters of deionized water and 0.8 liters of triethylene glycol, first add 20g nickel nitrate hexahydrate, add 6g ferric chloride hexahydrate after dissolving, add 15g urea after ultrasonic dispersion for 30 minutes, and stir for 1 hour , to form a uniform reaction solution;

[0029] Step (2) The reaction solution is placed in a hydrothermal kettle for heating reaction, the heating temperature is 115 ° C, and the heating time is 28 hours; after the reaction, filter and wash 3 times with absolute ethanol, put it into the ethanol solution and soak for 22 hours, Washed with absolute ethanol twice, dried in a vacuum oven at 60°C for 28 hours to obtain NiFe-LDH powder;

[0030] Step (3) Dissolve 2.2 grams of NiFe-LDH powder in 1 liter of deionized water, and then add 0.2 grams of K 2 PdCl 4 and 0.02 g CuCl 2 .2H2 O, fully dissolved; take NaBH with a concentration of 0.9 mmol / L 4 The solution was 1.2 liters, added in 15 times, 80 ml each time, and stirred ...

Embodiment 3

[0034] Step (1) mix 0.18 liters of deionized water and 0.82 liters of triethylene glycol, first add 30g nickel nitrate hexahydrate, add 5g ferric chloride hexahydrate after dissolving, add 10g urea after ultrasonic dispersion for 20 minutes, and stir for 2 hours , to form a uniform reaction solution;

[0035] Step (2) The reaction solution is placed in a hydrothermal kettle for heating reaction, the heating temperature is 120 ° C, and the heating time is 26 hours; after the reaction, first filter and wash 2 times with deionized water, and then filter and wash with absolute ethanol for 2 times. times, soaked in ethanol solution for 24 hours, washed 3 times with absolute ethanol, and dried in a vacuum oven at 65°C for 26 hours to obtain NiFe-LDH powder;

[0036] Step (3) Dissolve 2.4 grams of NiFe-LDH powder in 1 liter of deionized water, and then add 0.12 grams of K 2 PdCl 4 and 0.03 g CuCl 2 .2H 2 O, fully dissolved; take NaBH with a concentration of 0.8mmol / L 4 The solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com