A laminated composite battery

A composite battery technology, which is applied in the direction of secondary batteries, battery components, hybrid capacitor electrodes, etc., can solve the problems of limited application and low energy density, and achieve high power density, high energy density, and short charge and discharge time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0197]

[0198] Exemplarily, the present invention also provides a method for preparing the above-mentioned composite battery, the method comprising the following steps:

[0199] (1) preparing a positive electrode sheet for a lithium ion battery and a positive electrode sheet for a supercapacitor; and / or, preparing a positive electrode sheet for a lithium ion battery and a supercapacitor;

[0200] (2) prepare negative plate;

[0201] (3) Lead out two independent positive pole tabs in the positive pole piece for lithium-ion batteries and the positive pole piece for supercapacitors, or lead out two independent positive pole lugs in the positive pole pieces for lithium-ion batteries and supercapacitors; A negative pole lug is drawn from the negative electrode sheet to form a three-pole lug structure with two mutually independent positive pole lugs and a common negative pole lug;

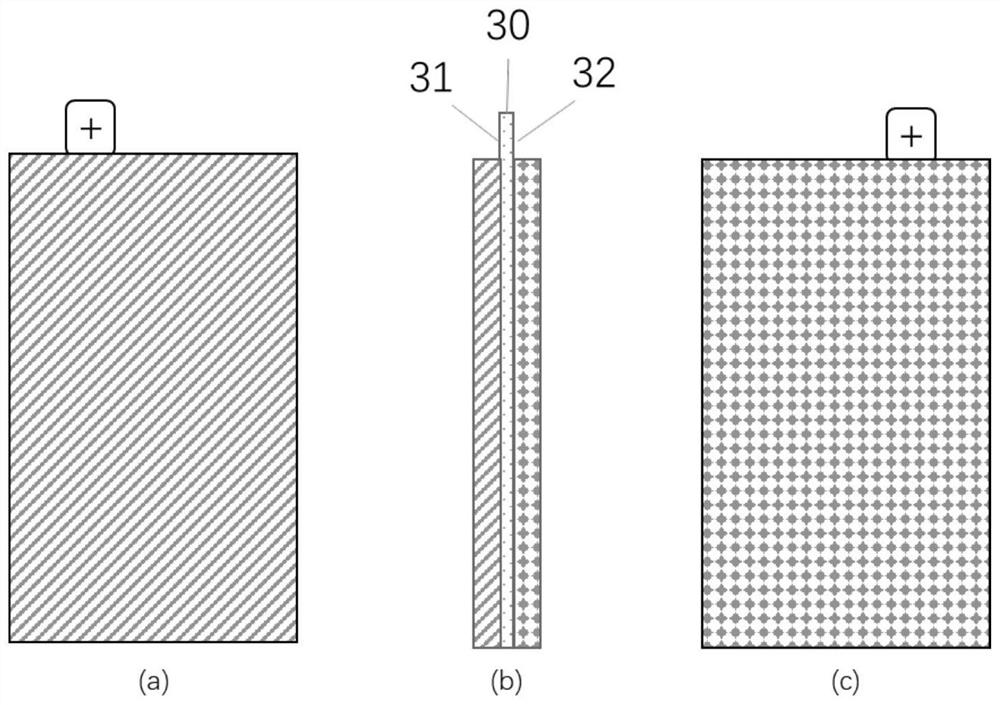

[0202] (4) The composite battery is formed by stacking alternately in the pattern of negative ele...

preparation example 1

[0219] Preparation Example 1 Positive electrode sheet for supercapacitor

[0220] Porous carbon activated carbon powder (specific surface area ≥ 1000m 2 / g), binder PVDF, conductive carbon black, and carbon nanotubes are mixed and dispersed in NMP (N-methylpyrrolidone), and after mixing, they are vacuum stirred to obtain a uniform dispersion to prepare a positive electrode slurry for supercapacitors. The solid component includes 93wt% positive active material, 4wt% binder PVDF, 2wt% conductive carbon black and 1wt% carbon nanotube. The total solid content in the positive electrode slurry for supercapacitor is 40wt%.

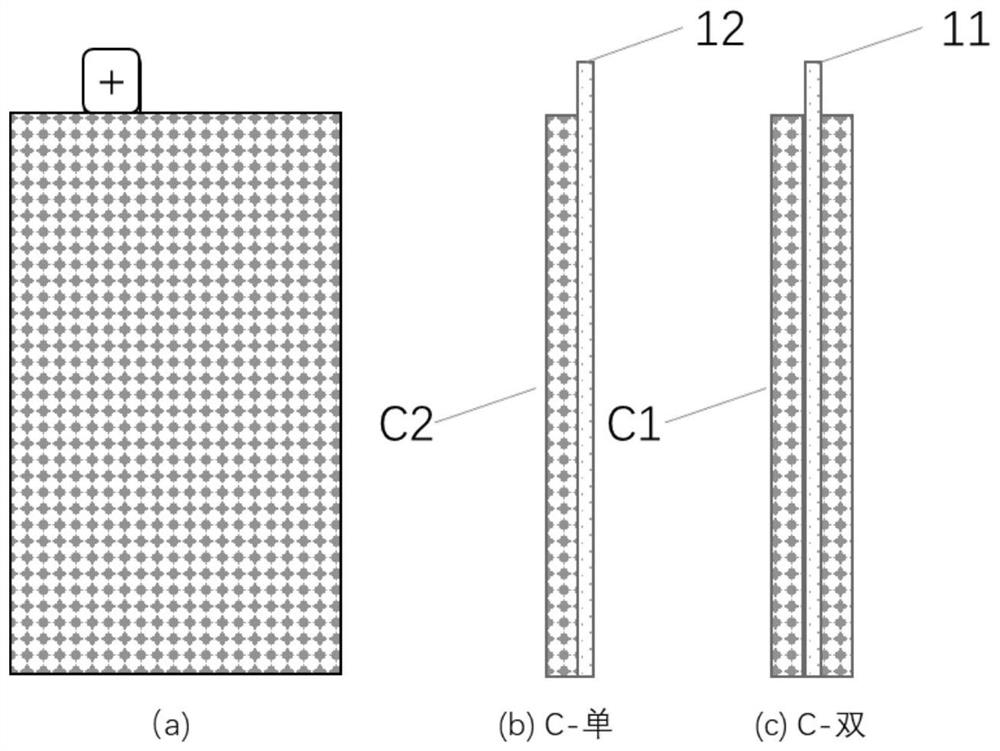

[0221] Apply the supercapacitor positive electrode slurry evenly on both sides of the aluminum foil, vacuum dry at 100-120°C for 10-24 hours, and roll until the compaction is 1.0-2.1g / cm 3 , to obtain a number of supercapacitors with positive plate C1 denoted as C-double (such as figure 1 (c) in).

[0222] Apply the positive electrode slurry for supercapacito...

preparation example 2

[0223] Preparation Example 2 Positive electrode sheet for lithium ion battery

[0224] The positive electrode active material (LiNi 0.8 co 0.1 mn 0.1 o 2 ), binder PVDF, conductive carbon black, and carbon nanotubes are mixed and dispersed in NMP, and after mixing, they are stirred in a vacuum to obtain a uniform dispersion to make a cathode slurry for lithium-ion batteries. The solid component includes 94wt% positive active material, 3wt% binder PVDF, 2wt% conductive carbon black and 1wt% carbon nanotube. The total solid content in the positive electrode slurry for lithium ion batteries is 70 wt%.

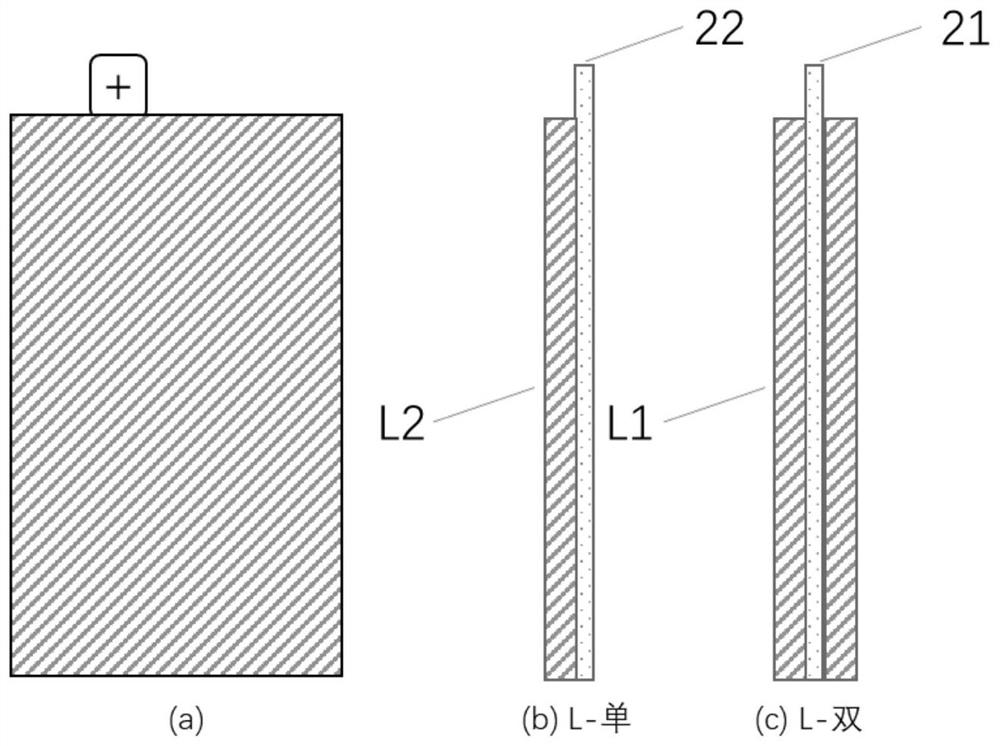

[0225]Apply the positive electrode slurry for lithium-ion batteries evenly on both sides of the aluminum foil, vacuum dry at 100-120°C for 10-24 hours, and roll until the compaction is 2-4.8g / cm 3 , to obtain the positive electrode sheet L1 for lithium-ion batteries is denoted as L-double (such as figure 2 (c) in).

[0226] Apply the positive electrode slurry for lithium-i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com