Targeted positioning type film coating premix and preparation method thereof

A film-coating, positioning-type technology, applied in the directions of pharmaceutical formulations, inactive medical preparations, inorganic inactive ingredients, etc., can solve the problems of decreased drug treatment effect, drug disintegration, etc. dosage, the effect of reducing dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

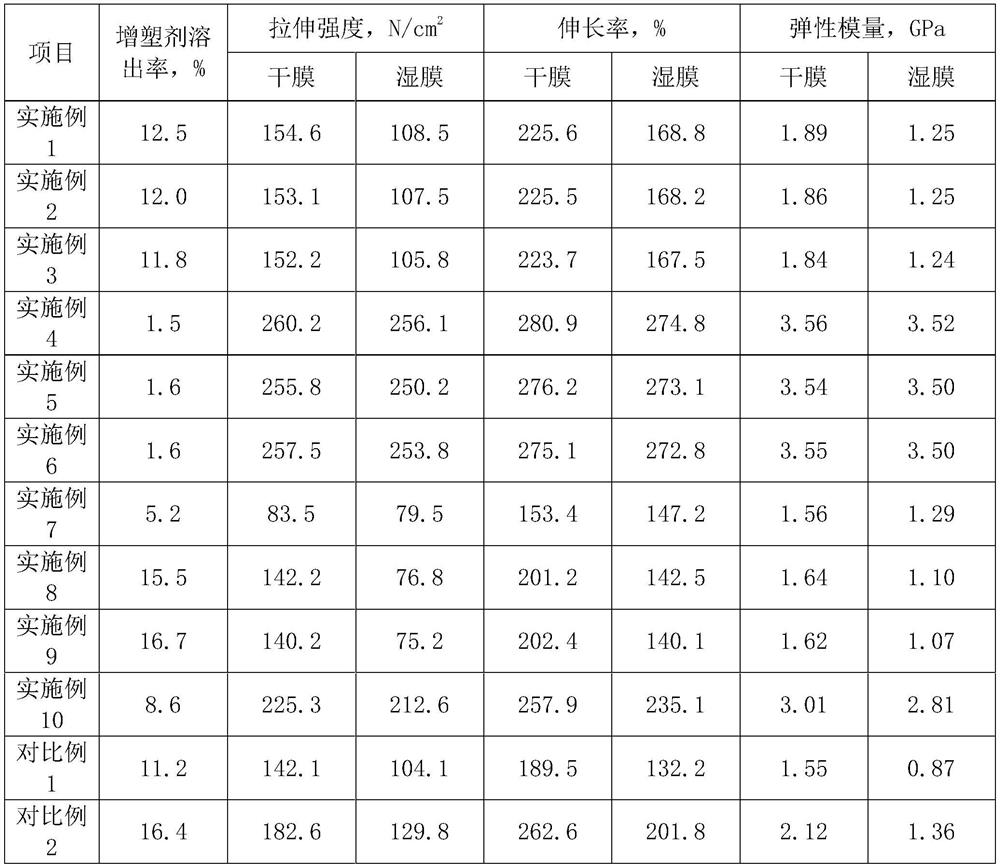

Examples

Embodiment 1

[0036] Example 1: A targeted positioning type film coating premix is prepared by the following method:

[0037]S1. Weigh 50kg of polyacrylic acid resin III, 22kg of Eudragit RS100, 10kg of talcum powder anti-sticking agent, 15kg of plasticizer, 2kg of Tween-80, 10kg of purified water, 3kg of ethanol with a volume fraction of 95%, and 1kg of color lake ; Wherein, plasticizer is made up of 5kg triethyl citrate and 10kg polyethylene glycol 6000;

[0038] S2. Take the polyacrylic resin III weighed in S1, Eudragit RS100, talcum powder, plasticizer, Tween-80, add water and ethanol with a volume fraction of 95% as a solvent, and use it at a speed of 2500r / min , mixed and stirred for 0.9h to obtain a blend;

[0039] S3, drying the blend solution at a temperature of 40° C. for 4.5 hours until the moisture content is ≤8%, to obtain a blend;

[0040] S4. Add color lake to the blend, pre-mix for 0.8h at a speed of 800r / min to obtain a premix; grind the premix for 5h at a speed of 3000...

Embodiment 2

[0041] Example 2: A targeted positioning type film coating premix is prepared by the following method:

[0042] S1. Weigh 45kg of polyacrylic acid resin III, 20kg of Eudragit RS100, 8kg of magnesium stearate anti-sticking agent, 12kg of plasticizer, 1kg of Tween-80, 10kg of purified water, 3kg of ethanol with a volume fraction of 95%, and 0.5 kg color lake; Wherein, plasticizer is made up of 4kg triethyl citrate and 8kg polyethylene glycol 6000;

[0043] S2. Take the polyacrylic resin III weighed in S1, Eudragit RS100, magnesium stearate, plasticizer, Tween-80, add water and ethanol with a volume fraction of 95% as a solvent, and use it at 2000r / min Speed, mixed and stirred for 0.8h to obtain a blend;

[0044] S3, drying the blend solution at a temperature of 35° C. for 5 hours until the moisture content is ≤8%, to obtain a blend;

[0045] S4. Add color lake to the blend, and pre-mix for 0.5h at a speed of 500r / min to obtain a premix; grind the premix for 4h at a speed of ...

Embodiment 3

[0046] Example 3: A targeted positioning type film coating premix is prepared by the following method:

[0047] S1. Weigh 55kg of polyacrylic resin III, 25kg of Eudragit RS100, 12kg of talcum powder anti-sticking agent, 18kg of plasticizer, 2kg of Tween-80, 10kg of purified water, 3kg of ethanol with a volume fraction of 95%, and 1kg of color lake ; Wherein, plasticizer is made up of 6kg triethyl citrate and 12kg polyethylene glycol 6000;

[0048] S2. Take the polyacrylic resin III weighed in S1, Eudragit RS100, talcum powder, plasticizer, Tween-80, add water and ethanol with a volume fraction of 95% as a solvent, and use it at a speed of 3000r / min , mixed and stirred for 1h to obtain a blend;

[0049] S3, drying the blend solution at a temperature of 45° C. for 4 hours until the moisture content is ≤8%, to obtain a blend;

[0050] S4. Add color lake to the blend, and pre-mix for 1 hour at a speed of 1000r / min to obtain a premix; grind the premix for 6 hours at a speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com