Built-in stainless steel skeleton plastic-wood composite decorative column and method

A stainless steel column, stainless steel technology, applied in covering/lining, construction, building structure, etc., can solve the problems of inconvenience, inconvenient installation and disassembly, and achieve the effect of increasing stability, prolonging service life, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

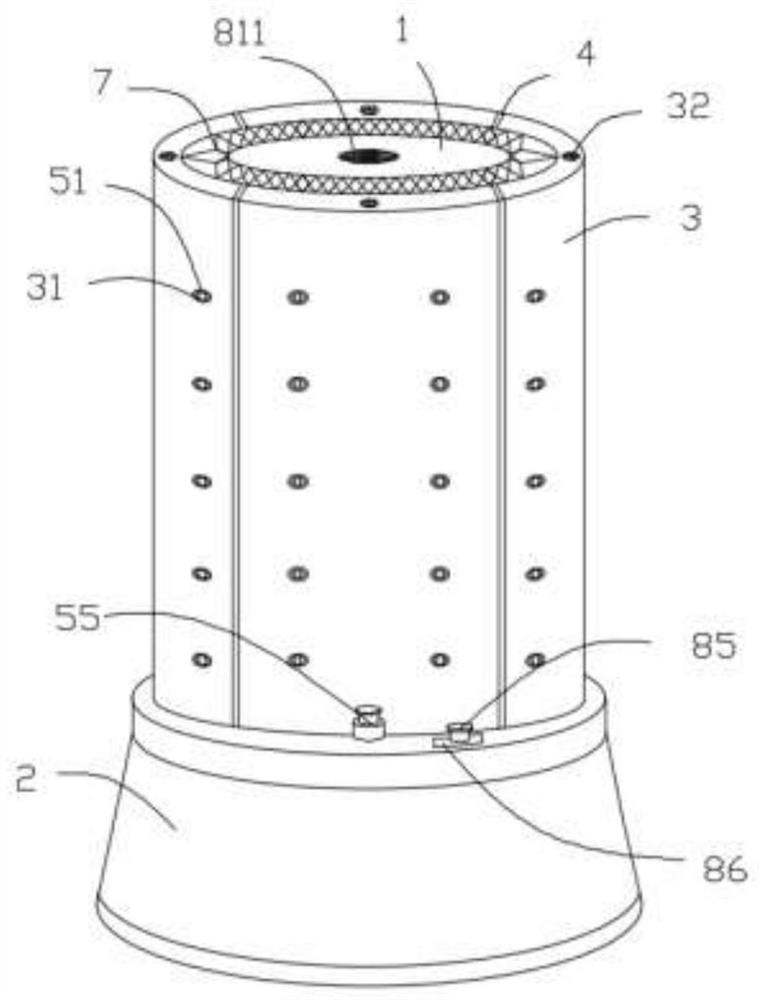

[0034] Such as figure 1 As shown, a plastic-wood composite decorative column with a built-in stainless steel skeleton mainly includes: a stainless steel column 1 arranged at the center of the decorative column for load-bearing, a base 2 arranged at the bottom of the stainless steel column 1, and surrounding the stainless steel column. 1. Four arc-shaped stainless steel casings of the same specification 3, and a plastic-wood composite board 6 installed on the outside of the stainless steel casing 3;

[0035] A locking mechanism 5 for convenient installation and disassembly of the plastic-wood composite board 6 is provided between the stainless steel shell 3 and the plastic-wood composite board 6;

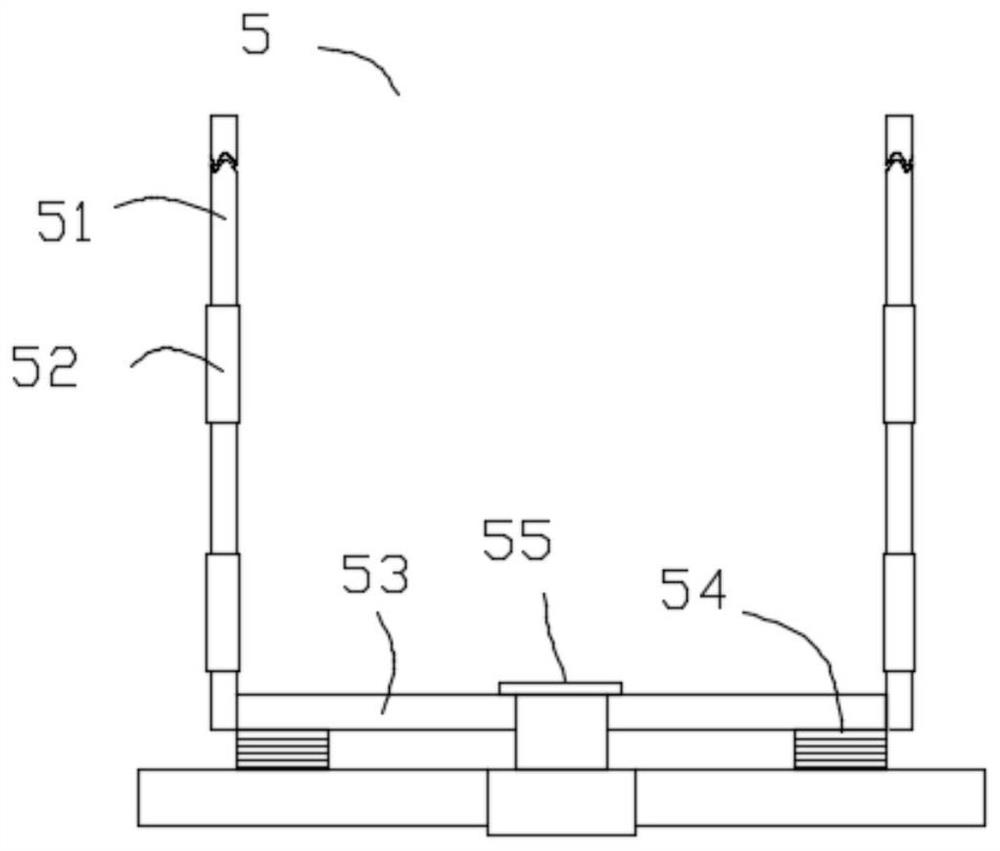

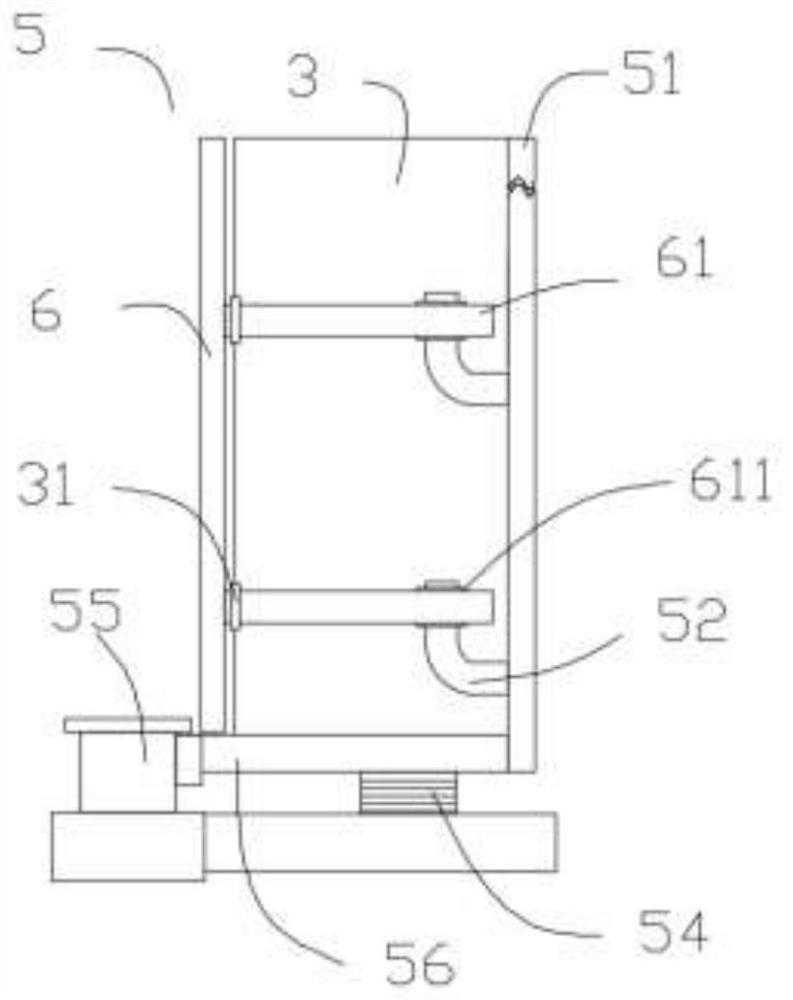

[0036] Such as figure 2 and image 3As shown, the locking mechanism 5 includes: two locking columns 51 vertically arranged in each stainless steel shell 3, a plurality of locking heads 52 arranged on each locking column 51, fixedly connected On the bottom end of each locking post...

Embodiment 2

[0041] Described embodiment 2 differs from described embodiment 1 in that:

[0042] Such as Figure 5 As shown, a filling mechanism 4 is arranged between each of the stainless steel shells 3;

[0043] The filling mechanism 4 includes: a connecting plate 41 fixedly connected to the stainless steel column 1, two filling plates 42 of the same specification telescopically arranged in the connecting plate 41, and filling plates 42 arranged between the filling plates 42. A bag 422, a rotating shaft 421 for rotating and connecting the two filling plates 42, the connecting plate 41 is provided with an adjustment button 43 for calling out the filling plate 42, the filling bag 422 is an inflatable air bag, It is inflated and deflated by an air pump.

[0044] The decorative column installation method of the second embodiment includes the following steps:

[0045] S1 Install the stainless steel column 1, the base 2 and the buffer mechanism 7: the stainless steel column 1 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com