Hybrid production scheduling management and control method for polycrystalline silicon rods

A polycrystalline silicon ingot and hybrid technology, which is used in instruments, manufacturing computing systems, data processing applications, etc., can solve the problems of unstable number of polycrystalline silicon ingots, low automation level, easy fatigue and slack, to improve capital turnover and prevent resources. The effect of waste and inventory reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

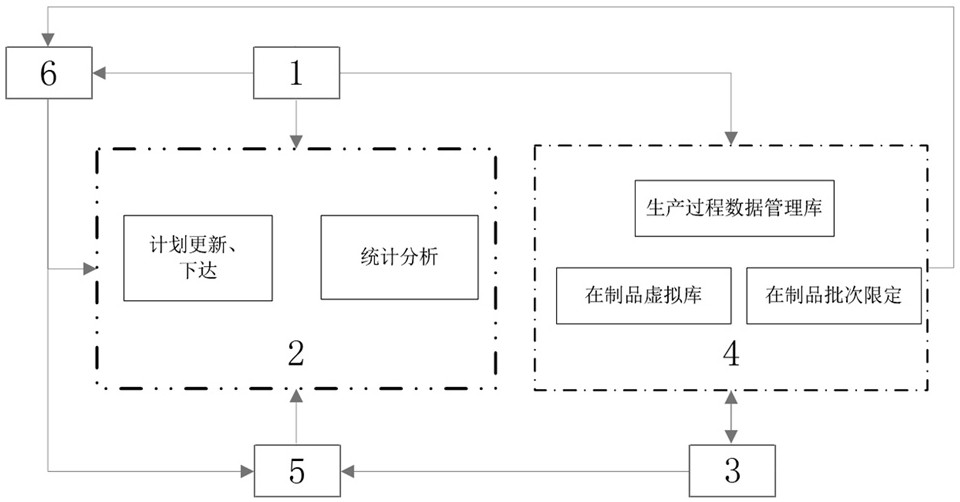

[0017] The invention provides a hybrid production scheduling control method for polycrystalline silicon rods, which mainly coordinates up and down during the production scheduling process of polycrystalline silicon rods to ensure the orderly operation of production, and reasonably allocates equipment and human resources to improve production efficiency; the control method adopts The control system mainly includes a data acquisition unit, a plan management unit, a plan adjustment unit, a standard man-hour management unit, a production process tracking unit and a first-in-first-out management unit.

[0018] When in use, plan managers are first required to enter the company's annual production tasks and monthly task goals into the data acquisition unit through the input method, and the data acquisition unit transmits relevant data to the plan management unit for annual plan and monthly plan management.

[0019] Then build a standard man-hour management unit based on lean productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com