A method for judging optical catastrophe type of semiconductor laser chip

A technology of optical catastrophe and laser, which is applied in semiconductor lasers, lasers, laser components, etc., can solve the problems of low production efficiency, high judgment cost, and long judgment time, and achieve the effects of low cost, improved efficiency, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

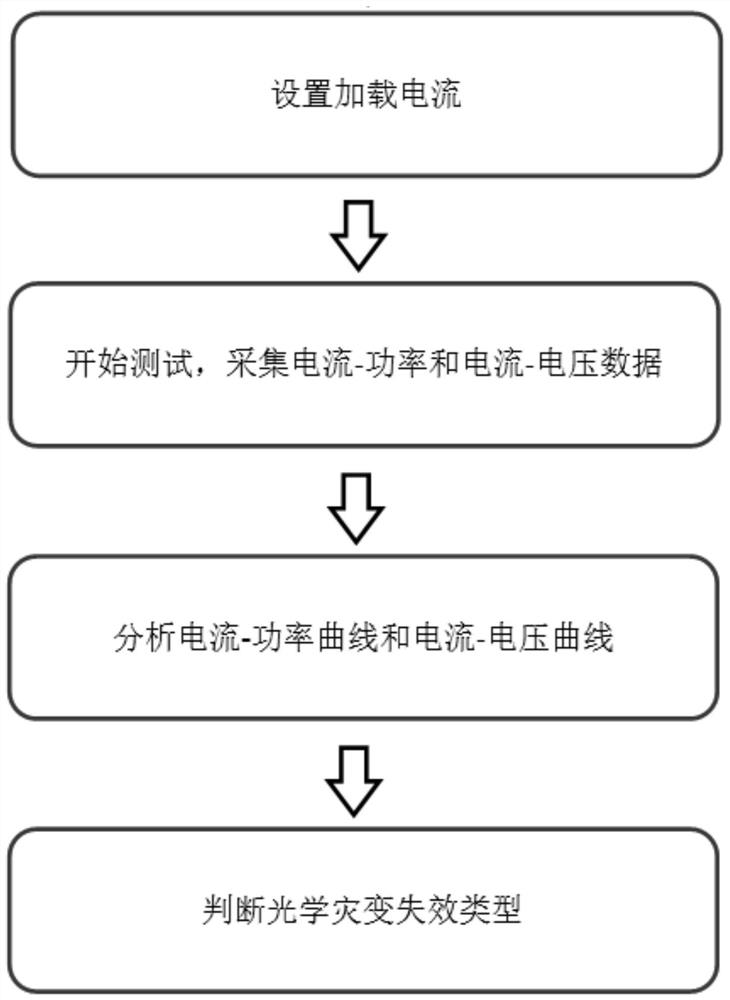

[0049] The present invention judges the method for semiconductor laser chip (bare chip) optical catastrophe type to comprise the following steps:

[0050] Step 1. Set the step size of the current rise and the maximum current (adjust accordingly according to the product type);

[0051] Step 2. Place the coated bare bar chip on the bar test bench, with the P side up (positive electrode), and the N side metal of the bar chip contacts the copper strip of the test bench, and the copper strip will be electrically connected to the negative electrode; Adjust the two probes of the test bench, apply current to one of the probes, and make contact with the P side of the bare bar chip, and the other probe collects the voltage of the bar chip;

[0052] Step 3, turn on the power supply, collect the current-power curve of the test chip, and collect the current-voltage curve at the same time;

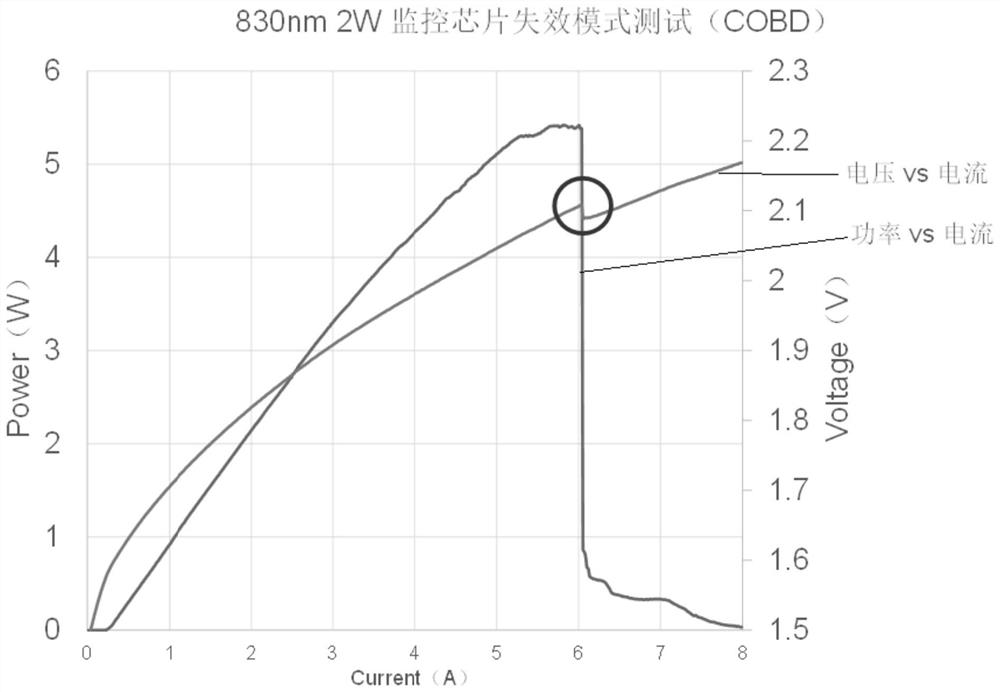

[0053] Step 4, analyze the current-power curve and current-voltage curve, such as figure 2 As sho...

Embodiment 2

[0055] The present invention judges the method for semiconductor laser chip (COS chip) optical catastrophe type to comprise the following steps:

[0056] Step 1. Set the step size of the current rise and the maximum current (adjust accordingly according to the product type);

[0057] Step 2. Install the packaged COS chip on the COS test fixture, and then install the test fixture on the COS test platform; connect the positive and negative electrodes to the COS test fixture, where the positive and negative electrodes are connected to the data acquisition card, which can collect current and voltage Data and power data are collected by an integrating sphere;

[0058] Step 3, turn on the power supply, collect the current-power curve of the test chip, and collect the current-voltage curve at the same time;

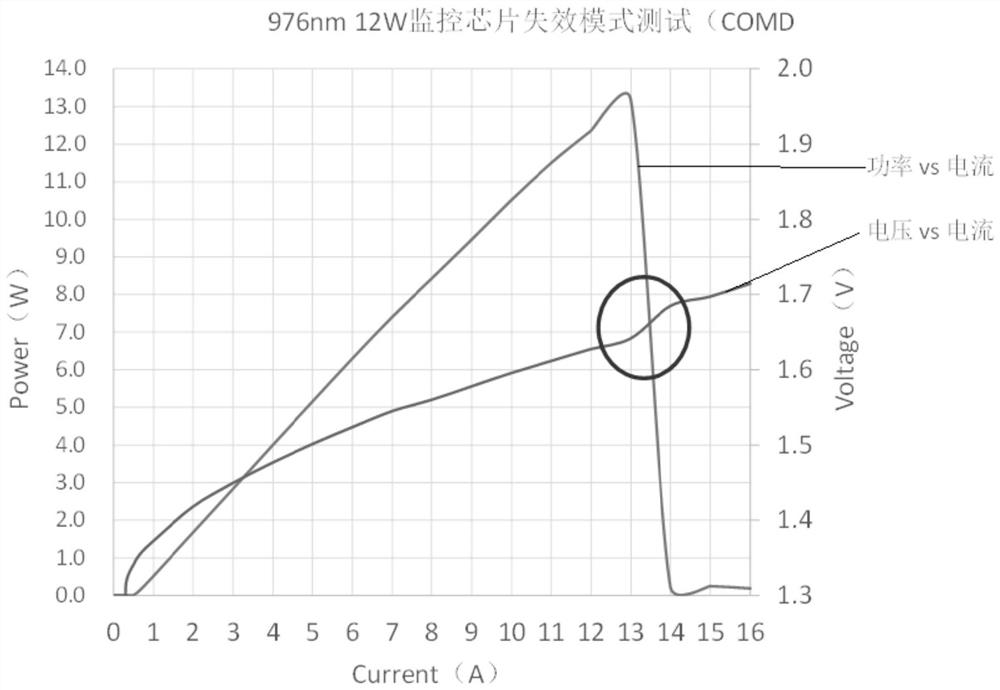

[0059] Step 4, analyze the current-power curve and current-voltage curve, such as image 3 As shown, the failure type is judged according to the change of the current-voltage ...

Embodiment 3

[0061] The present invention judges the method for the optical catastrophe type of semiconductor laser chip (COS chip aging) to comprise the following steps:

[0062] Step 1. Set the aging current;

[0063] Step 2. Install the packaged COS chip on the COS aging fixture, and then install the aging fixture on the COS aging cabinet; add the aging current required by the product to the COS aging cabinet, where the positive and negative poles of the COS aging fixture are connected to the data acquisition card, which can Collect current and voltage data, and power data is collected by an integrating sphere;

[0064] Step 3, monitoring the power value change trend and the voltage value change trend of COS device aging;

[0065] Step 4. Analyze the power trend curve and voltage value trend curve of COS device aging. When the monitored power value suddenly drops and the voltage value drops, it is judged that the failure of the COS device is COBD; if the power value suddenly drops, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com