Decorative round bamboo and manufacturing method

A technology of round bamboo and decorative layer, which is applied to the surface coating liquid device, special surface, pretreatment surface, etc., which can solve the problem of large consumption of abrasive belt/sandpaper, insufficient durability of decorative effect, poor treatment effect, etc. problems, to achieve good decorative effects, rich and stable colors, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with the accompanying drawings, the specific embodiments of the present invention will be further described in detail, so as to make the technical solution of the present invention easier to understand and grasp.

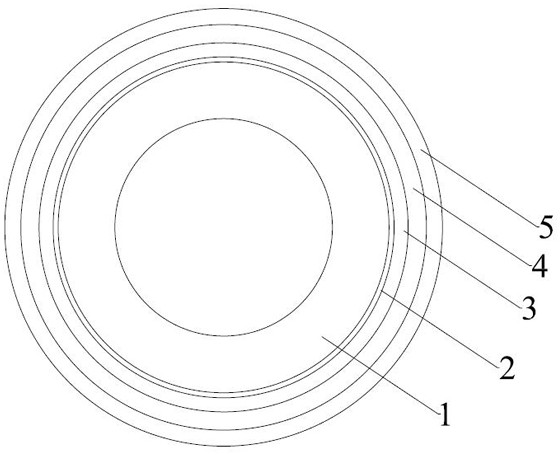

[0031] Such as figure 1 As shown, a round bamboo for decoration, the innermost layer is a round bamboo substrate 1, and the outermost layer is a decorative layer 5. Wherein, an interface layer 2 is provided on the outer surface of the round bamboo substrate 1 , and a waterproof layer 4 is provided between the interface layer 2 and the decoration layer 5 .

[0032] A more optimal embodiment is that an adhesion layer 3 is provided between the waterproof layer 4 and the interface layer 2 to improve the adhesion strength between the waterproof layer 4 and the decoration layer 5 . Adhesion layer 3 is a mixture of additives such as polyurethane and adhesion promoter, among which the adhesion promoter can be γ-glycidyl etheroxypropylmethyldieth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com