Conformal coating based on butadiene styrene rubber as well as preparation method and use method thereof

A technology of styrene-butadiene rubber and three-proof paint, applied in the field of coatings, can solve the problems of easy clogging of spray guns, poor light and aging resistance, poor construction performance, etc., to optimize the protective performance of the paint film, increase the adhesion of the paint film, excellent three The effect of anti-effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

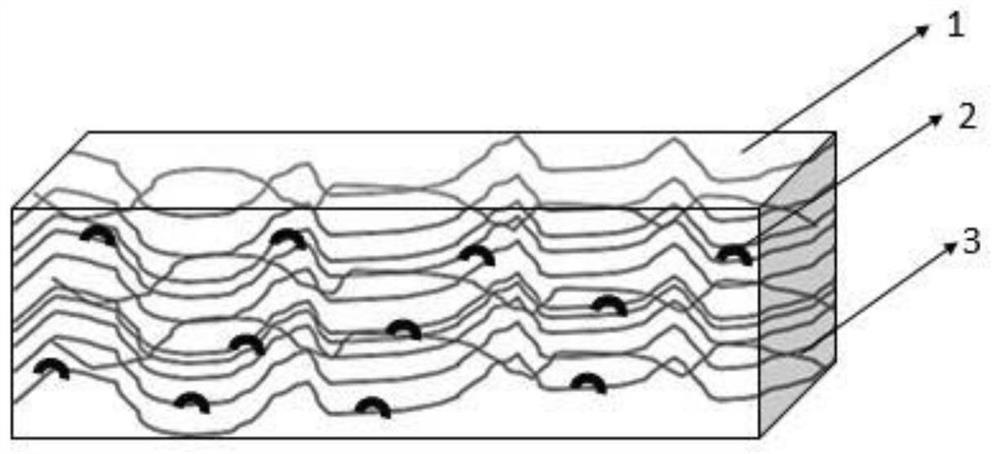

Image

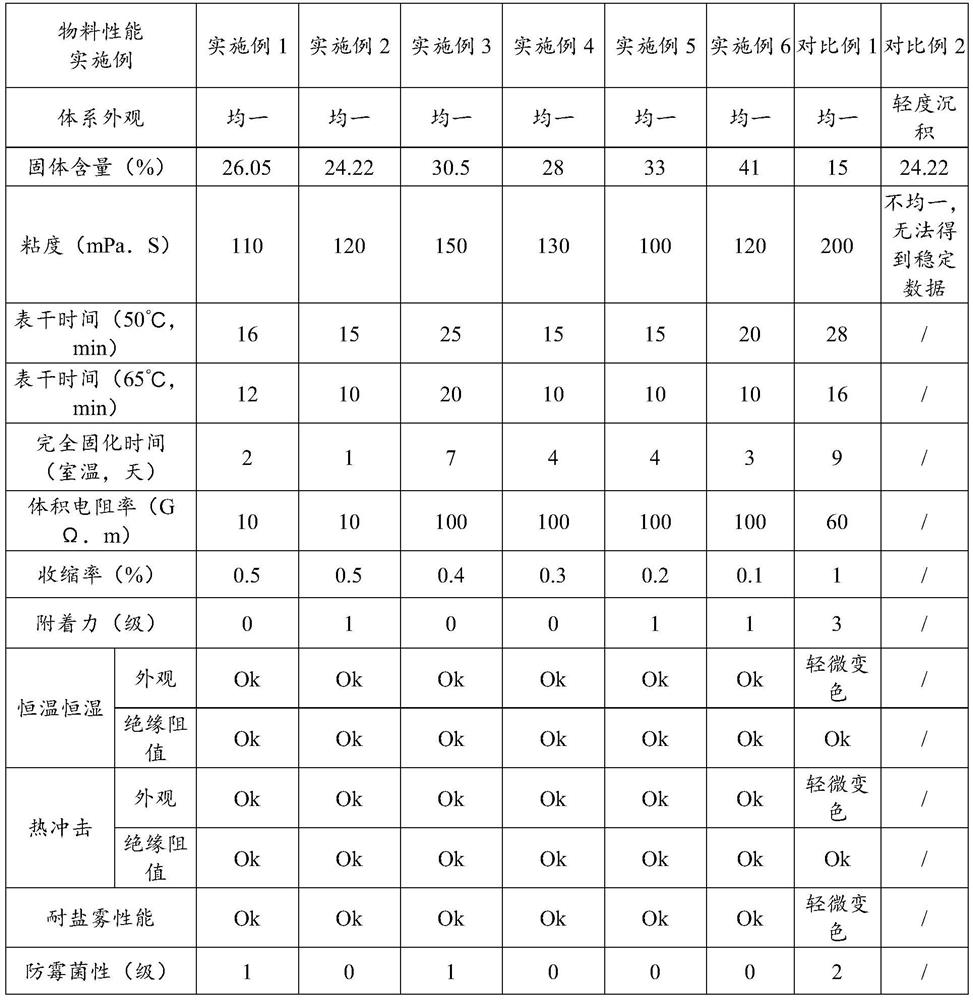

Examples

preparation example Construction

[0103] The preparation method of the invention only needs conventional equipment, has low preparation cost, simple preparation process and is easy to popularize and apply.

[0104] In the present invention, each component is mixed according to the specific addition order of the present invention, which helps to obtain a uniform and stable system.

[0105] In a third aspect, the present invention provides a method for using the conformal paint based on styrene-butadiene rubber in the first aspect, including:

[0106] First, the substrate is coated with the above-mentioned conformal paint based on styrene-butadiene rubber;

[0107] Then, let the substrate coated with conformal paint stand for 1 to 3 minutes, and then preheat it at 50 to 65°C for 5 to 25 minutes to achieve surface dryness;

[0108] Finally, the substrate after the surface intervention treatment is placed at room temperature for 1 to 7 days to complete the complete curing process.

[0109] The coating method in ...

Embodiment 1

[0117] A conformal paint based on styrene-butadiene rubber, including 0.01% styrene-butadiene rubber, 0.01% organosiloxane, 69.94% type I thinner, 30% type II thinner, 0.01% dispersant, anti 0.01% aging agent, 0.01% fluorescent agent, 0.01% leveling agent.

[0118] The styrene-butadiene rubber is obtained by copolymerizing butadiene monomer and styrene monomer.

[0119] The type I diluent is a C6-C12 aliphatic hydrocarbon solvent, and the type II diluent is an aromatic hydrocarbon solvent.

[0120] The dispersant is dispersant KMT-4006; the antiaging agent is antiaging agent IRGANOX565; the fluorescent agent is fluorescent powder for high-pressure mercury lamps.

[0121] The leveling agent is leveling agent KMT-7019.

[0122] The preparation method of the above-mentioned three anti-paint based on styrene-butadiene rubber comprises the following specific steps:

[0123] Weigh each component by proportioning;

[0124] Add styrene-butadiene rubber and Type I diluent into the ...

Embodiment 2

[0130] A conformal paint based on styrene-butadiene rubber, including 1% styrene-butadiene rubber, 0.01% organosiloxane, 95% type I thinner, 0.5% type II thinner, 0.01% dispersant, anti- 3% aging agent, 0.38% fluorescent agent, 0.1% thixotropic agent.

[0131] The styrene-butadiene rubber is obtained by copolymerizing butadiene monomer and styrene monomer.

[0132] The type I diluent is a C6-C12 aliphatic hydrocarbon solvent, and the type II diluent is a ketone solvent.

[0133] The dispersant is dispersant DISPERBYK 163; the antiaging agent is aging agent IRGANOX B900 and antiaging agent TINUVIN 571; the fluorescent agent is fluorescent powder for ultraviolet light source; the thixotropic agent is thixotropic agent BYK-410 .

[0134] The preparation method of the above-mentioned three anti-paint based on styrene-butadiene rubber comprises the following specific steps:

[0135] Weigh each component by proportioning;

[0136] Add styrene-butadiene rubber and type I diluent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com