Surface treatment liquid, surface treatment method and tin-plated steel sheet by surface treatment

A technology of surface treatment liquid and tin-plated steel plate, which is applied in the coating process of metal materials, etc., can solve the problems such as corrosion resistance and sulfur spot resistance, and achieve excellent sulfur spot resistance, significant economic benefits, and protection environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

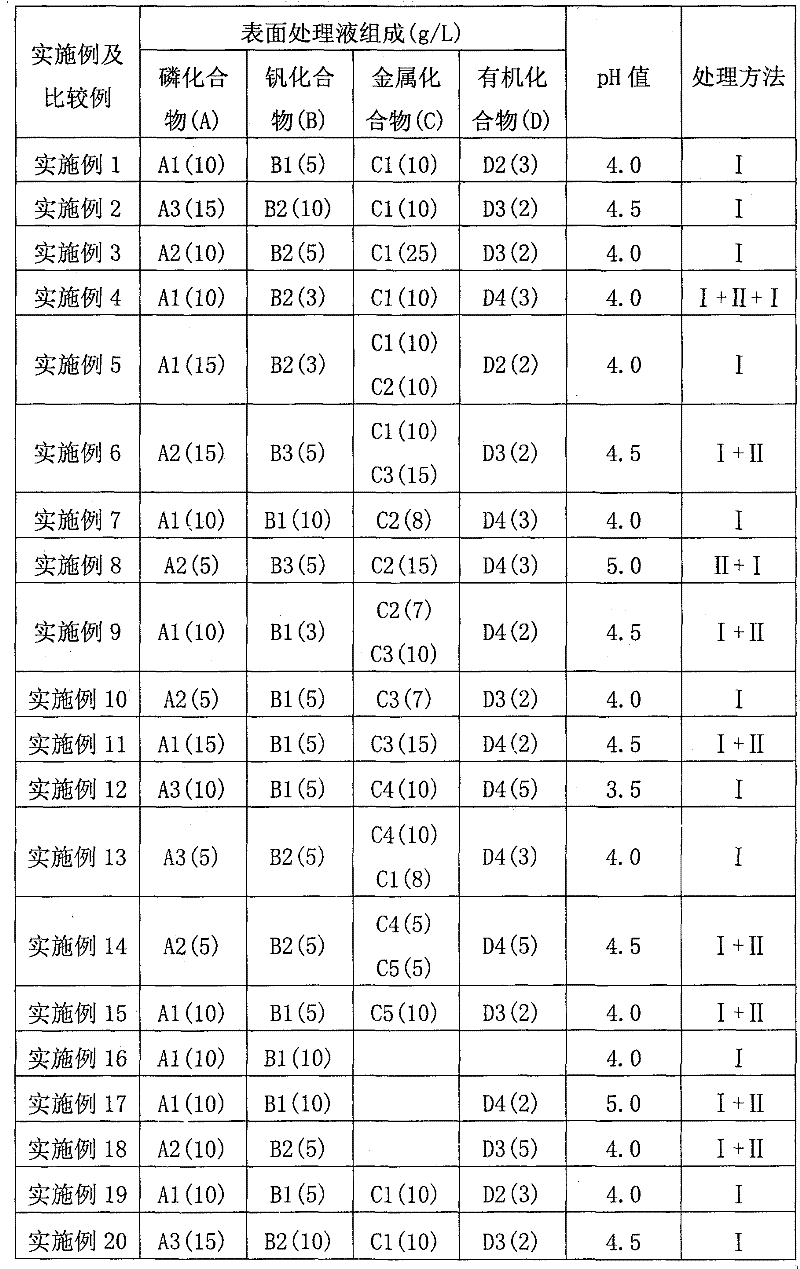

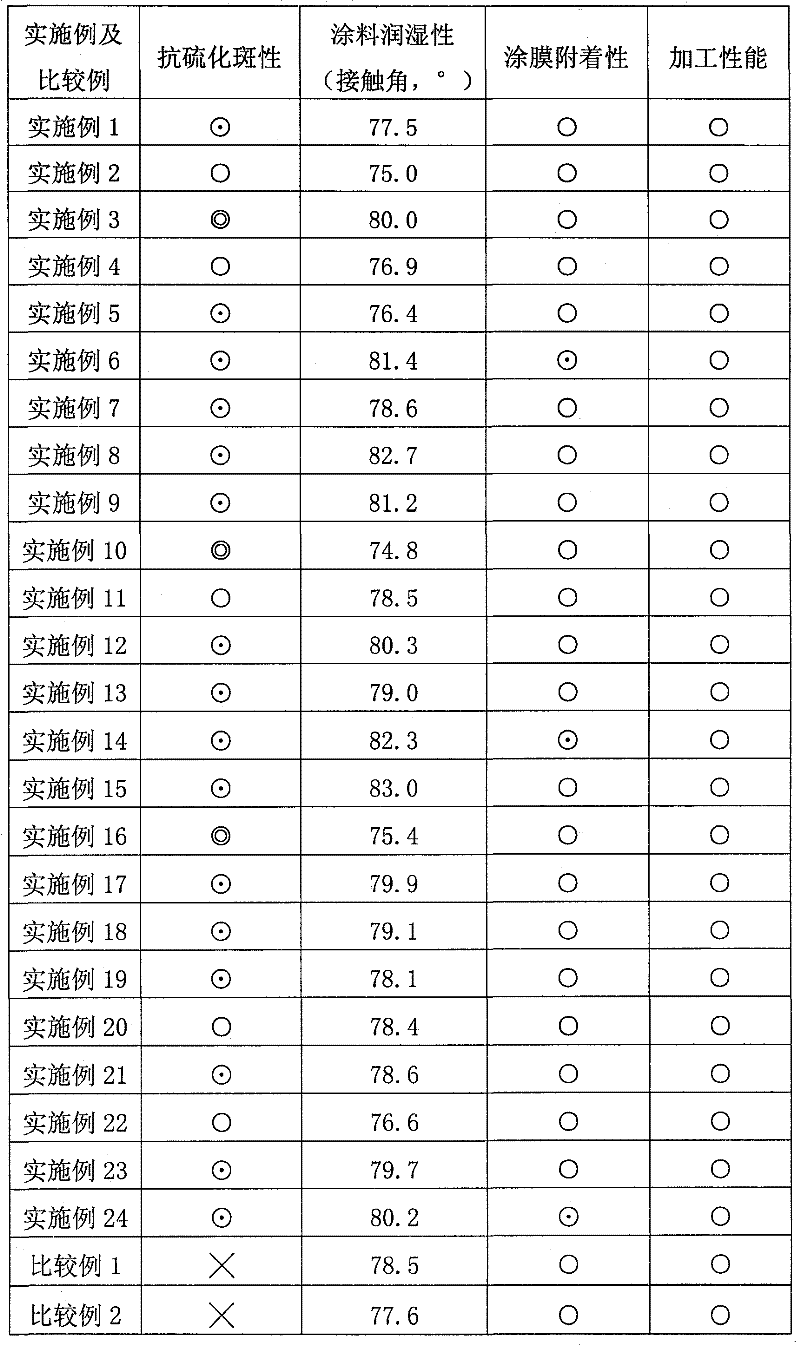

Examples

Embodiment 1~18

[0049] The sample preparation is carried out in the following way: After electrolytic degreasing of 0.2mm thick T4 cold-rolled steel plate, it is annealed in a continuous annealing furnace. The atmosphere in the furnace is 5%volH2+95volN2 gas, and the maximum heating temperature is 720°C. After annealing, a leveling treatment with an elongation rate of 2% is carried out. Then the steel plate can be prepared for tin plating after pretreatment such as degreasing and pickling. Tin plating is carried out in phenol sulfonate tin plating solution (PSA), and the tin plating weight is 5.6g / m2. The process conditions of tin plating solution are as follows:

[0050] PSA: Sn2+: 28g / L

[0051] Phenolsulfonic acid: 16g / L

[0052] Bath temperature: 45°C

[0053] Current density: 20A / dm 2

[0054] Reflow treatment is performed on the tin-plated steel sheet at a temperature above the melting point of tin to form a Sn-Fe alloy layer between the steel substrate and the tin layer. The sur...

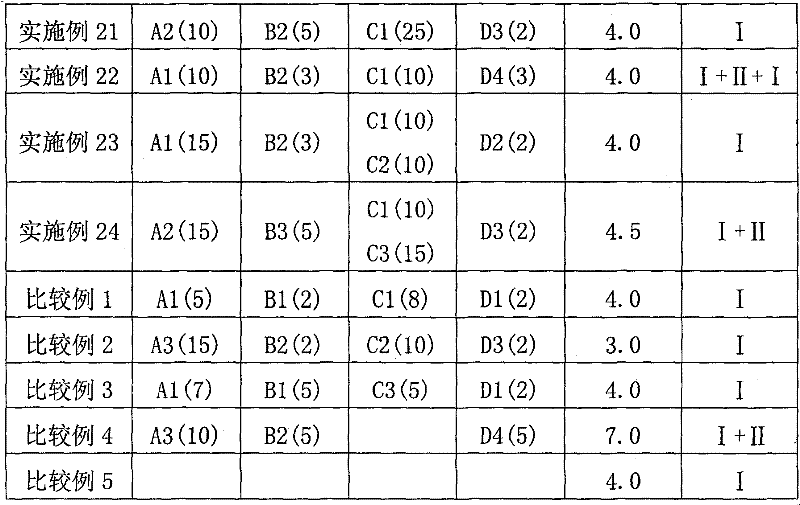

Embodiment 19~24

[0056] Except that MSA plating solution is used for electroplating tin, other conditions are the same as those in Examples 1-6.

[0057] MSA: Sn2+: 21g / L

[0058] Methanesulfonic acid: 30g / L

[0059] Bath temperature: 30°C

[0060] Current density: 20A / dm 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com