Processing method of integrated quartz vibrating beam side electrode

A technology of side electrode and processing method, which is applied in the process of producing decorative surface effects, gaseous chemical plating, metal material coating process, etc., can solve the problems of difficult mechanical alignment and fixing error, deterioration of dimensional accuracy, etc., Achieve the effect of improving machining accuracy, simplifying process flow, and ensuring dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

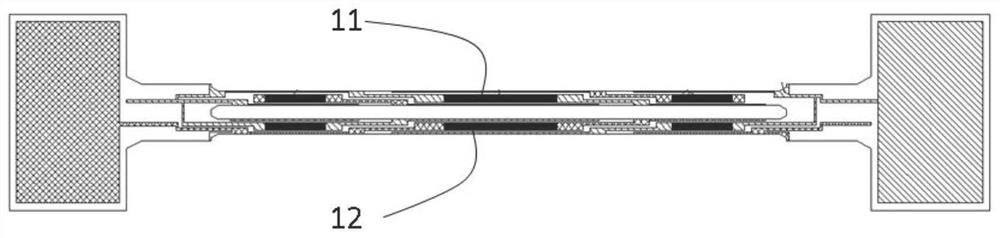

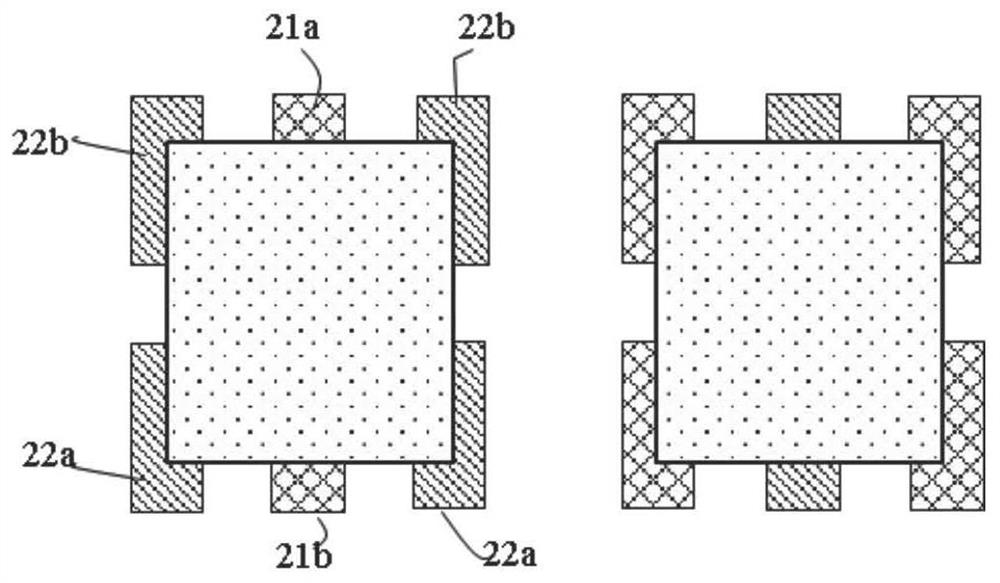

[0040] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0041] The processing method of the side electrode of the integrated quartz vibration beam specifically includes the following steps:

[0042] In the first step, the Figure 4 The shown quartz wafer 1 is chemically etched and polished so that the error range of the thickness of the quartz wafer 1 is within ±0.5 microns. The diluted hydrofluoric acid etching solution is selected as the chemical etching agent, and the etching rate is about 0.1 micron per minute by adjusting the concentration of the etching solution and the temperature of the solution, so as to improve the corrosion flatness. A quartz wafer with an initial thickness of 242 microns is put into a hydrofluoric acid etching solution and etched for 10 minutes to make the thickness of the quartz wafer reach 240 microns. After the processing is completed, carry out the standard cleani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com