Antibacterial anticorrosive coating for building exterior wall and preparation method thereof

An antibacterial and anti-corrosion technology, applied to anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problem of single bactericidal effect and achieve high-efficiency bactericidal effect, high-efficiency anti-bacterial performance, and good waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of this coating is as follows:

[0037] The first step is to mix the silicone acrylic emulsion, perfluorosiloxane resin, hydroxyethyl cellulose and half of the additives into the stirring tank according to the parts by weight, and stir at a stirring speed of 300r / min for 20-30min at room temperature. get base material;

[0038] The second step is to add chlorinated paraffin, ammonium trimolybdate, antibacterial agent and the remaining half of the additives to the base material, stir and mix at 600r / min for 40-50min at room temperature, and then increase the speed to 2000r / min min stirring and mixing for 8-10 min to obtain antibacterial and antiseptic coatings.

Embodiment 1

[0040] An antibacterial anticorrosion coating for building exterior walls, made of the following raw materials in parts by weight: 55 parts of silicone acrylic emulsion, 9 parts of perfluorosiloxane resin, 3 parts of antibacterial agent, 2 parts of hydroxyethyl cellulose, chlorinated 0.5 parts of paraffin, 0.3 parts of ammonium trimolybdate, 0.8 parts of additives;

[0041] This antibacterial anticorrosion coating is made by following steps:

[0042] The first step is to mix the silicone acrylic emulsion, perfluorosiloxane resin, hydroxyethyl cellulose and half of the additives into the stirring tank according to the parts by weight, and stir at a stirring speed of 300r / min for 20min at room temperature to obtain the base material;

[0043] The second step, add chlorinated paraffin, ammonium trimolybdate, antibacterial agent and the remaining half of the additives to the base material together, stir and mix at 600r / min for 40min at room temperature, and then increase the spee...

Embodiment 2

[0045] An antibacterial anticorrosion coating for building exterior walls, made of the following raw materials in parts by weight: 60 parts of silicone acrylic emulsion, 11 parts of perfluorosiloxane resin, 3.5 parts of antibacterial agent, 2.5 parts of hydroxyethyl cellulose, chlorinated 0.6 parts of paraffin, 0.35 parts of ammonium trimolybdate, 0.9 parts of additives;

[0046] This antibacterial anticorrosion coating is made by following steps:

[0047] The first step is to mix silicone acrylic emulsion, perfluorosiloxane resin, hydroxyethyl cellulose and half of the additives into the stirring tank according to the parts by weight, and stir at a stirring speed of 300r / min for 25min at room temperature to obtain the base material;

[0048] The second step, add chlorinated paraffin, ammonium trimolybdate, antibacterial agent and the remaining half of the additives to the base material together, stir and mix at 600r / min for 45min at room temperature, and then increase the sp...

PUM

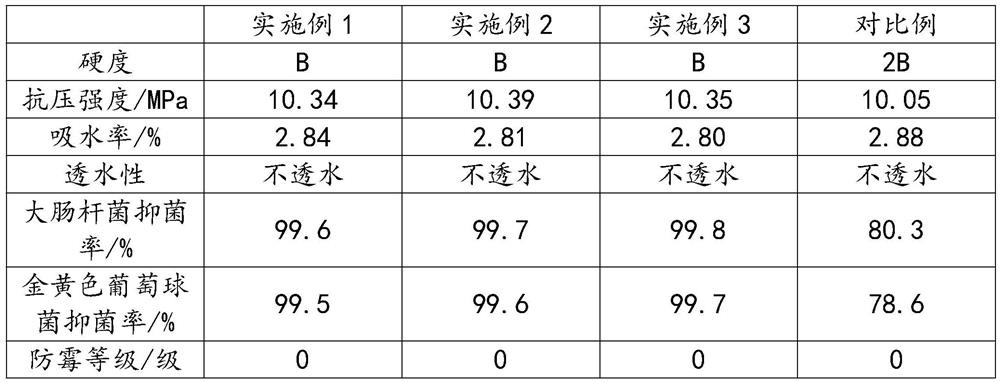

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com