Dust removal/hydrolysis integrated desulfurization system for blast furnace gas

A technology of desulfurization system and blast furnace gas, which is applied in the direction of gas dust removal, combustible gas purification, combustible gas purification/transformation, etc. It can solve the problems of low site utilization and difficult implementation, avoid site occupation, and solve the problem of excessive flue gas emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0019] The invention provides an integrated desulfurization system for blast furnace gas dedusting and hydrolysis.

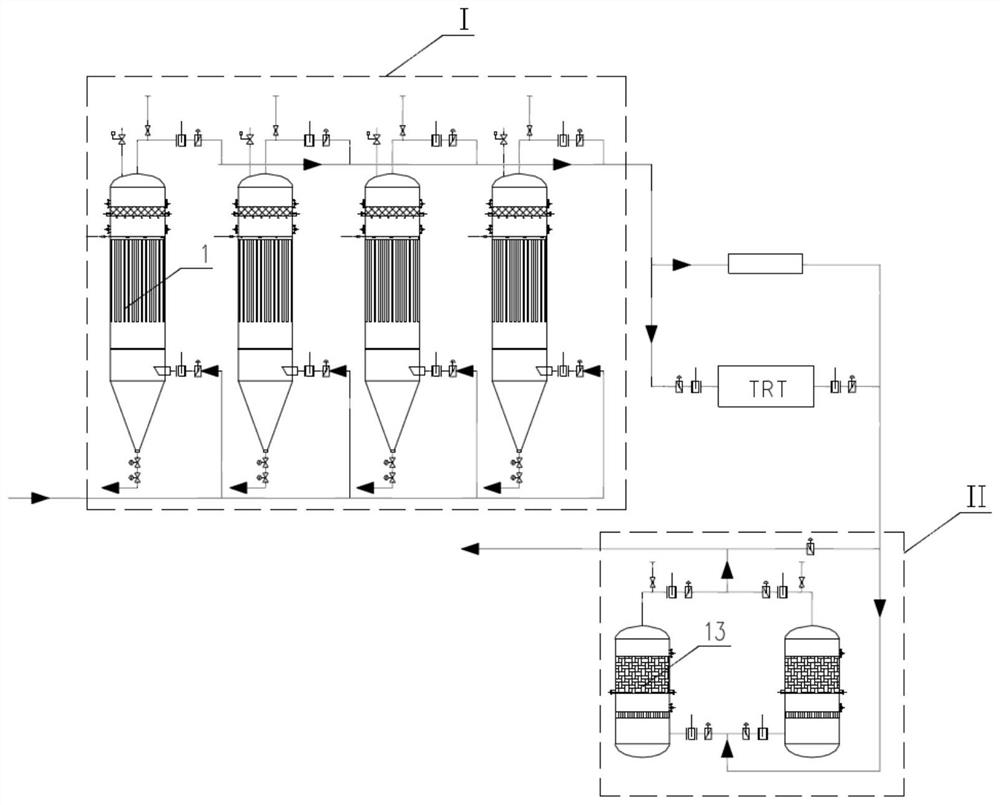

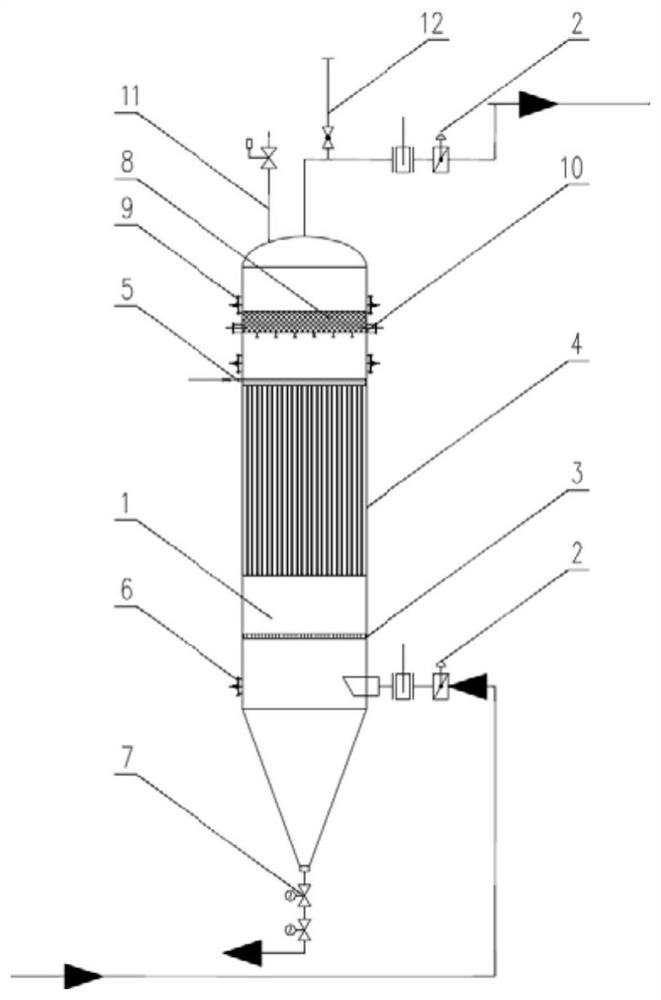

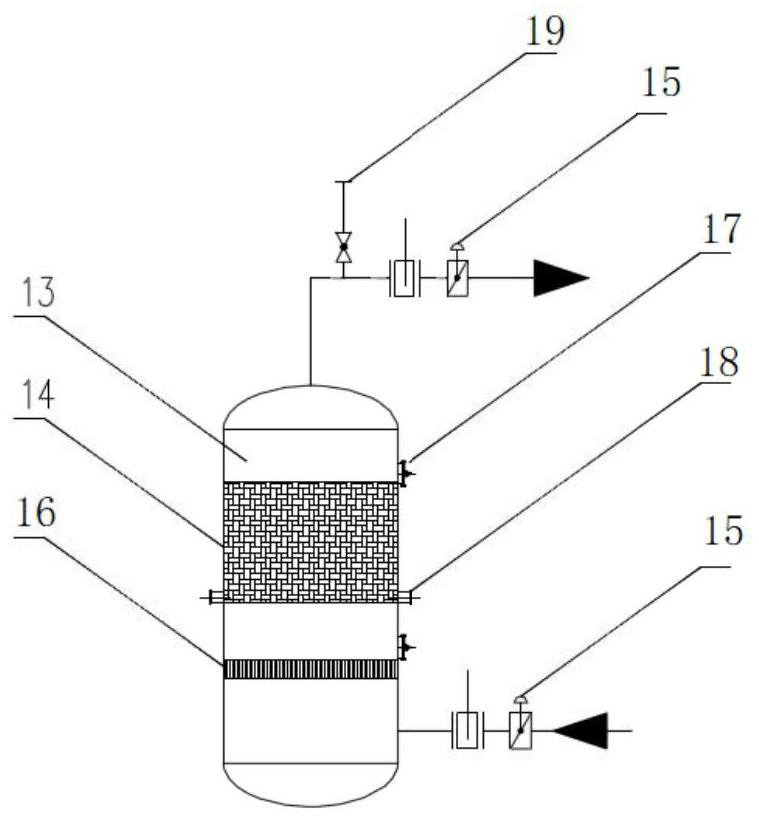

[0020] Such as figure 1 As shown, the system includes dust removal and hydrolysis integrated system I and desulfurization system II, such as figure 2 As shown, the dust removal and hydrolysis integrated system 1 includes a plurality of parallel dust removal and hydrolysis integration devices 1, and the dust removal and hydrolysis integration device 1 includes a cut-off valve group-2, an air flow uniform distribution plate-3, a cloth bag 4, nitrogen blowback 5, maintenance Manhole 6, unloading / ash conveying system 7, hydrolysis catalyst 8, loading hole 9, unloading hole 10, overpressure relief device 11 and safety release device 12, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com