Preparation method of high-speed steel roll with compound modification treatment

A compound metamorphic, high-speed steel technology, applied in the field of steel rolling, can solve problems such as coarse carbide structure on the roll body, decreased strength and toughness of high-speed steel rolls, and high price of vanadium elements, and achieve good high temperature wear resistance, good fatigue resistance, Excellent antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

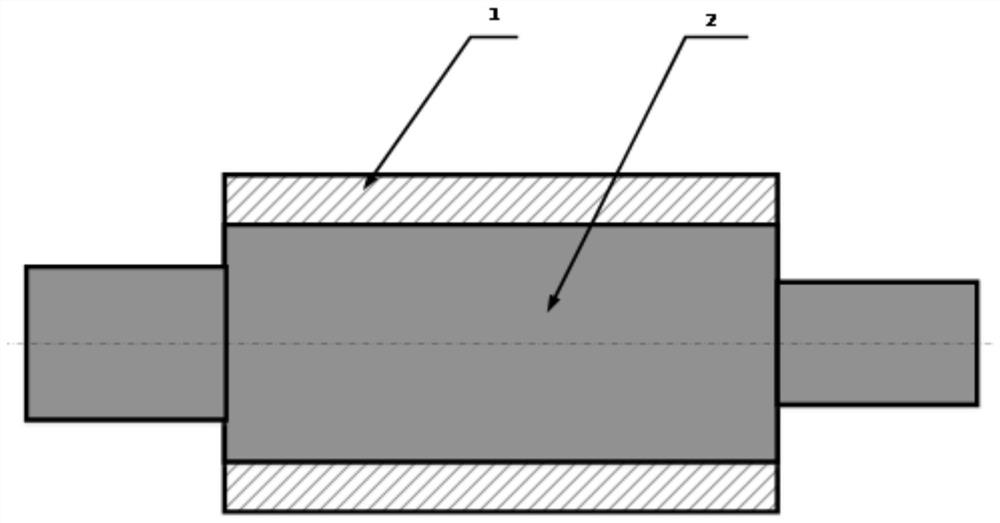

[0030] A method for preparing high-speed steel rolls with composite metamorphism treatment. The high-speed steel is smelted in a 1,000-kg medium-frequency induction furnace, and the high-speed steel for the roll working layer 1 is poured by a centrifuge. The specific process steps are as follows:

[0031] ① Melt the high-speed steel roll material in a 1000kg medium-frequency induction furnace first, and control the chemical composition and mass fraction of molten steel in the furnace at 2.32%C, 4.33%W, 4.80%Mo, 9.85%Cr, 0.48%Mn, 0.81 %Si, 0.031%S, 0.038%P, the balance Fe; then raise the temperature of the molten steel to 1615°C, keep it warm for 5 minutes, add metal aluminum accounting for 0.45% of the molten steel in the furnace for deoxidation and alloying, and continue to keep warm for 6 minutes Finally, add ferroboron (the chemical composition and massfraction of described ferroboron is: 19.89%B, 0.21%C, 1.25%Si, 0.19%Al, 0.008%S, 0.064%P , the balance of Fe) for alloying,...

Embodiment 2

[0036] A method for preparing high-speed steel rolls with composite metamorphism treatment. The high-speed steel is smelted in a 1,000-kg medium-frequency induction furnace, and the high-speed steel for the roll working layer 1 is poured by a centrifuge. The specific process steps are as follows:

[0037] ① Melt the high-speed steel roll material in a 1000kg medium-frequency induction furnace first, and control the chemical composition and mass fraction of molten steel in the furnace at 2.49%C, 4.17%W, 4.98%Mo, 9.63%Cr, 0.66%Mn, 0.57 %Si, 0.030% S, 0.031% P, the balance of Fe; then raise the temperature of the molten steel to 1626°C, keep it warm for 4 minutes, add metal aluminum accounting for 0.50% of the molten steel in the furnace for deoxidation and alloying, and continue to keep warm for 6 minutes Finally, add ferroboron (the chemical composition and massfraction of described ferroboron is: 20.42%B, 0.14%C, 0.82%Si, 0.26%Al, 0.005%S, 0.083%P , the balance Fe) for alloyin...

Embodiment 3

[0042] A method for preparing high-speed steel rolls with composite metamorphism treatment. The high-speed steel is smelted in an intermediate frequency induction furnace weighing 1500 kilograms, and the high-speed steel for the working layer 1 of the roll is poured by a centrifuge. The specific process steps are as follows:

[0043] ① Melt the high-speed steel roll material in a 1500 kg medium-frequency induction furnace first, and control the chemical composition and mass fraction of molten steel in the furnace at 2.38%C, 4.25%W, 4.90%Mo, 9.77%Cr, 0.52%Mn, 0.76 %Si, 0.034% S, 0.037% P, the balance of Fe; then raise the temperature of the molten steel to 1622°C, keep it warm for 5 minutes, add metal aluminum accounting for 0.48% of the molten steel in the furnace for deoxidation and alloying, and keep the temperature for 6 minutes Finally, add ferroboron (the chemical composition and massfraction of described ferroboron is: 20.17%B, 0.34%C, 1.26%Si, 0.29%Al, 0.007%S, 0.054%P ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com