Non-woven fabric dyeing device for production

A technology of dyeing device and non-woven fabric, which is applied in the directions of cleaning device for processing textile materials, equipment configuration for processing textile materials, textiles and papermaking, etc. Avoid uneven dyeing, avoid dyeing liquid precipitation, and mix evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

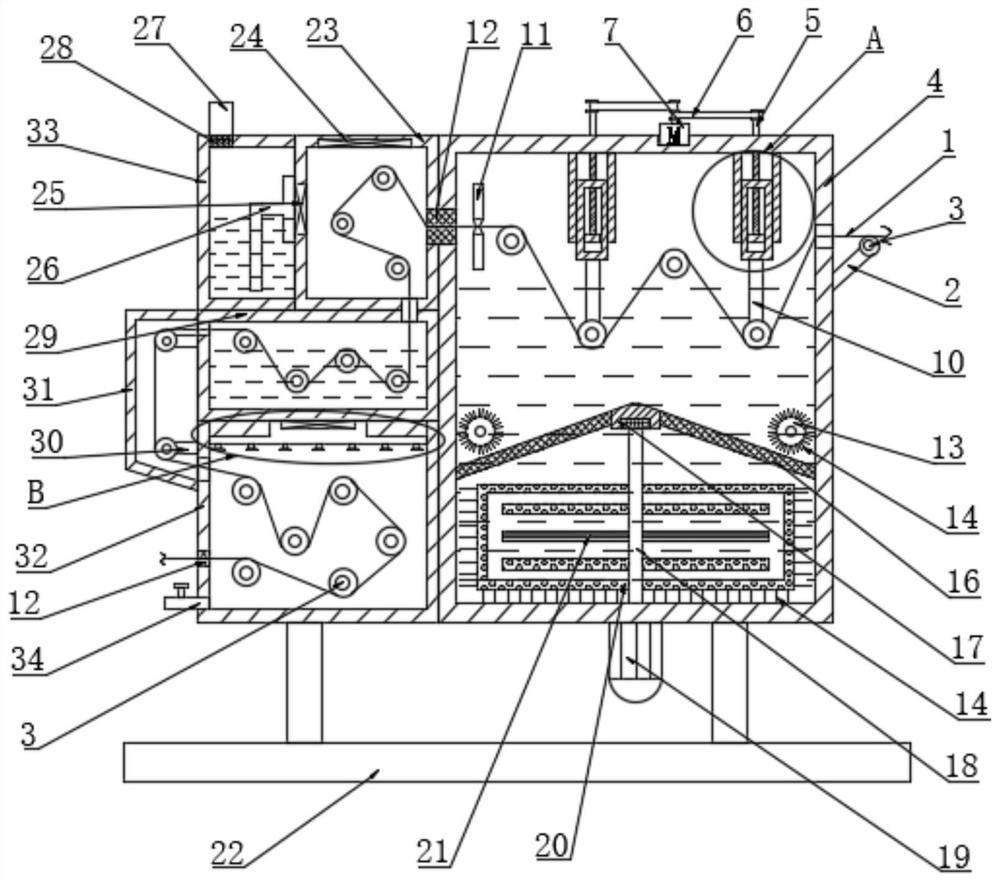

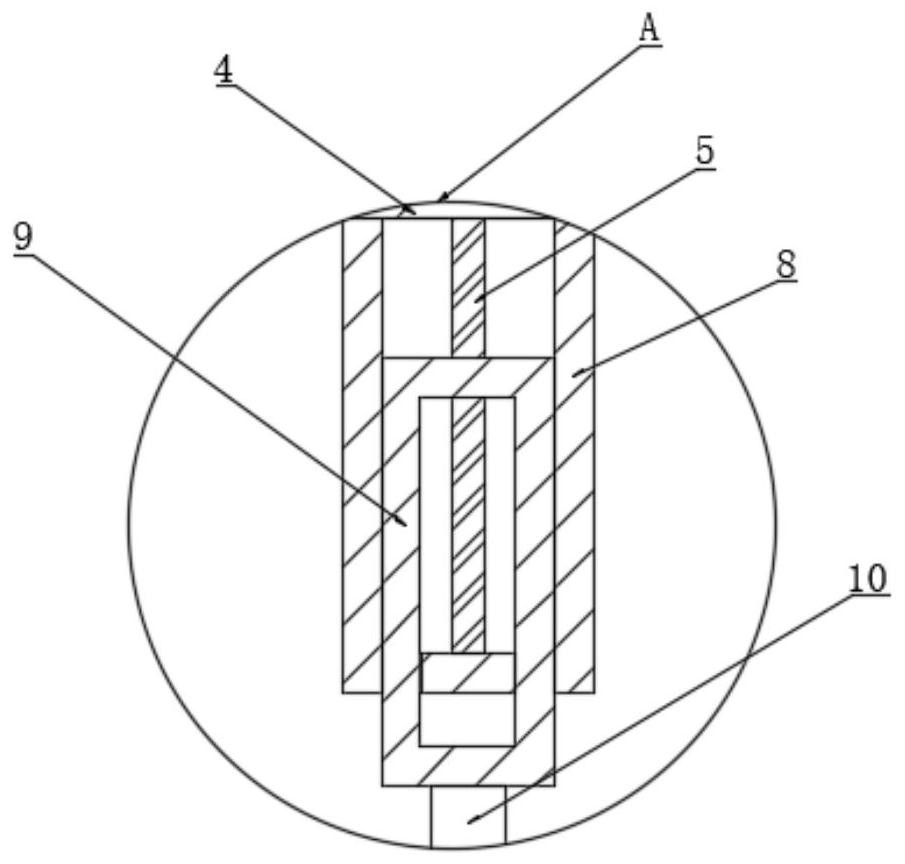

[0026] see figure 1 , figure 2 and Figure 4 , a non-woven fabric dyeing device for production, comprising a non-woven fabric 1, the non-woven fabric 1 is passed through the inside of a dyeing box 4, the dyeing box 4 is provided with a dyeing solution for dyeing, and the dyeing box 4 is provided with several first rollers 3, the non-woven fabric 1 is slidably connected to the first rollers 3, the top of the dyeing box 4 is fixedly connected with a lifting assembly, and the bottom of the lifting assembly is fixedly connected There is a first rotating roller 3, and the lifting assembly includes a first rotating shaft 5, and the first rotating shaft 5 runs through the top of the dyeing box 4 and is connected with a first motor 7 through a synchronous belt 6.

[0027]Further, the outer side of the non-woven fabric 1 is fixedly connected with the first rotating roller 3 through the first supporting seat 2, and the dyeing box 4 is provided with a feeding port for the non-woven fa...

Embodiment 2

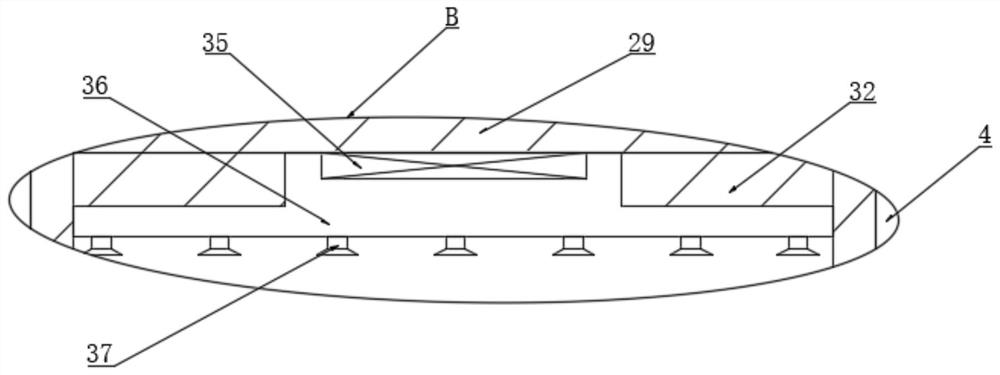

[0032] see figure 1 and Figure 4 , a non-woven fabric dyeing device for production, comprising a non-woven fabric 1, and a dyeing box 4, the bottom of the dyeing box 4 is provided with a stirring heating assembly, and the stirring heating assembly includes a stirring blade 20 and a heating rod 21 A filter screen 16 is provided above the stirring blade 20 , and cleaning components are provided on both sides of the filter screen 16 .

[0033] Further, the stirring blade 20 and the heating rod 21 are fixedly connected to the second rotating shaft 18, the stirring blade 20 is provided with a plurality of small holes, the two sides and the bottom of the stirring blade 20 are fixedly connected with a brush 14, One end of the second rotating shaft 18 is fixedly connected to the output shaft of the third motor 19, the third motor 19 is fixedly connected to the outer bottom of the dyeing box 4, and the other end of the second rotating shaft 18 is connected to a shunt through the rota...

Embodiment 3

[0040] see figure 1 and Figure 4 , a non-woven fabric dyeing device for production, comprising a non-woven fabric 1, and a dyeing box 4, the dyeing box 4 communicates with the inside of the cooling box 23, and the first rotating roller 3 is arranged in the cooling box 23 One side of the cooling box 23 is fixedly connected to a filter box 33, and a filter assembly is arranged in the filter box 33.

[0041] Further, the first roller 3 in the cooling box 23 is connected to the inside of the cooling box 23 through a rotating shaft, the top of the cooling box 23 is fixedly connected with a cooling fan 24, and the connection between the cooling box 23 and the filter box 33 An exhaust fan 25 is fixedly connected at the place, and the exhaust fan 25 is provided with an exhaust duct 26 facing the side of the filter box 33, and the exhaust duct 26 is fixedly connected to the inside of the filter box 33, and the filter box 33 is provided with a useful For the odor-purifying aqueous so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com