Construction process of pile-first-method sleeving type jacket of offshore wind power booster station

A technology of offshore wind power and construction technology, applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve the problems affecting the verticality and relative accuracy of piles, long welding time, high requirements for verticality and relative accuracy, etc., and achieve saving The effect of shortening the construction period, improving construction efficiency, and reducing construction risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

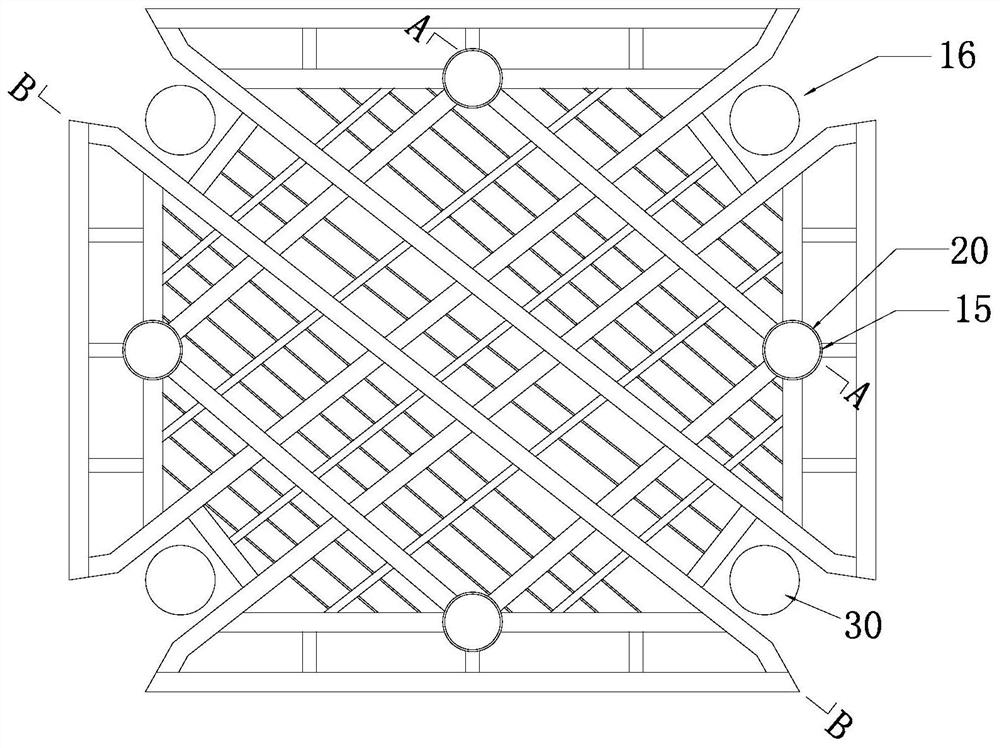

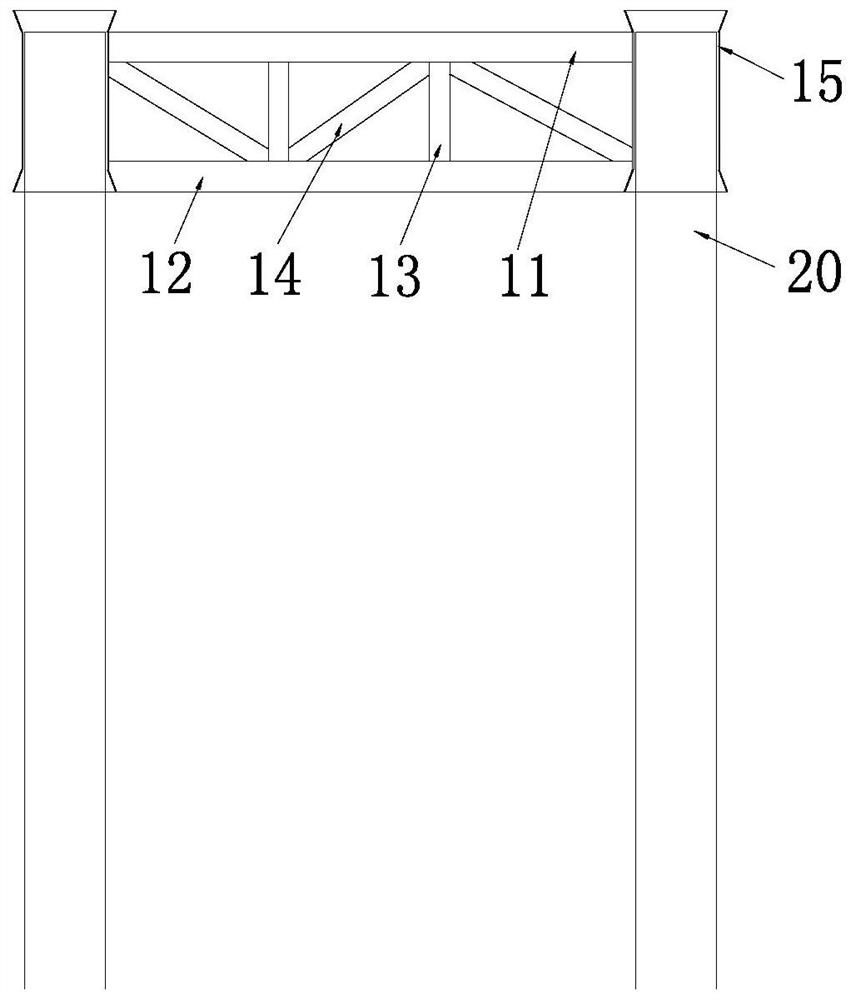

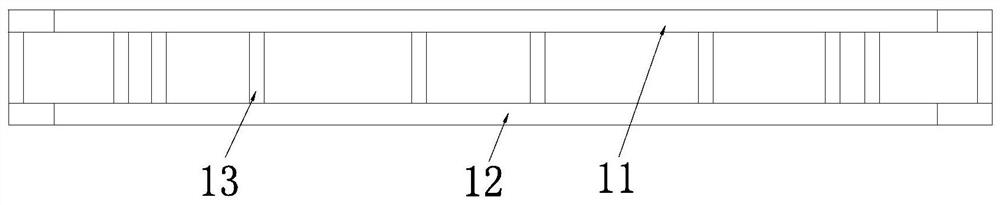

[0035] The present invention will be further described below in conjunction with accompanying drawing.

[0036] see Figure 1 to Figure 6 , the construction technology of the offshore wind power booster station of the present invention is the pile-first method of jacket type jacket, comprising the following steps: positioning of the construction platform for stabilizing piles, insertion and driving of auxiliary piles, fixing of construction platforms for stabilizing piles, sinking steel pipe piles, and steel pipe piles Rock-socketed construction, demolition of pile stabilization platform, jacket installation, jacket grouting, foundation anti-scouring protection and connection of booster station platform and jacket.

[0037] When performing the positioning step of the pile-stabilizing construction platform, the pile-stabilizing construction platform, auxiliary piles and steel pipe piles are manufactured in the factory, and then the construction platform, auxiliary piles and ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com