Method for judging number of layers of graphene oxide based on thermal enhanced optical contrast

An optical contrast and graphene technology, which is used in material analysis, scientific instruments, color/spectral property measurement and other directions by optical means, can solve problems such as inapplicability, and achieve the effect of low detection cost and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

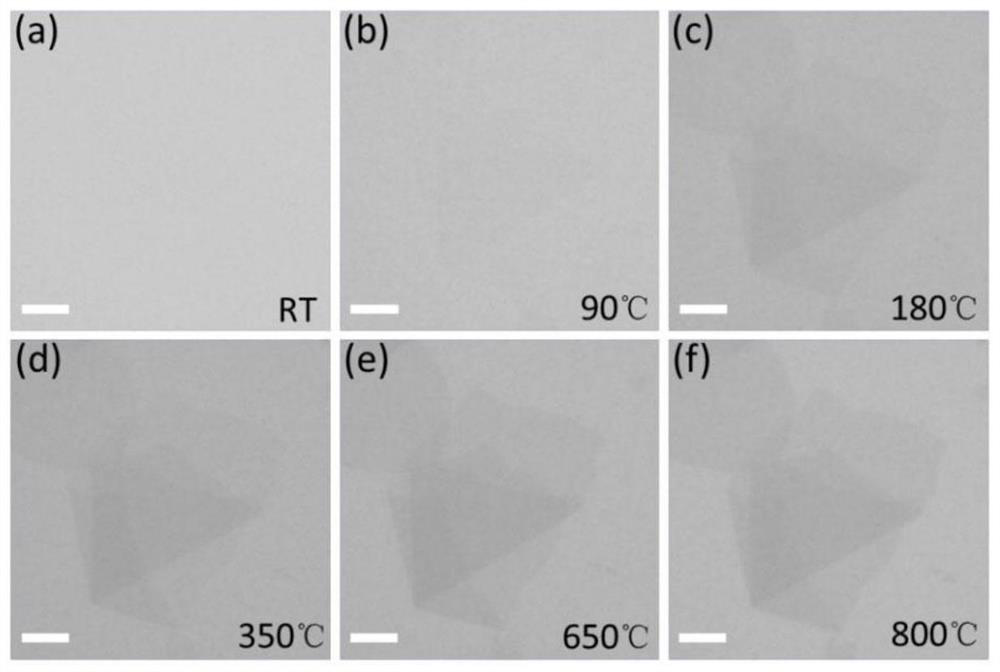

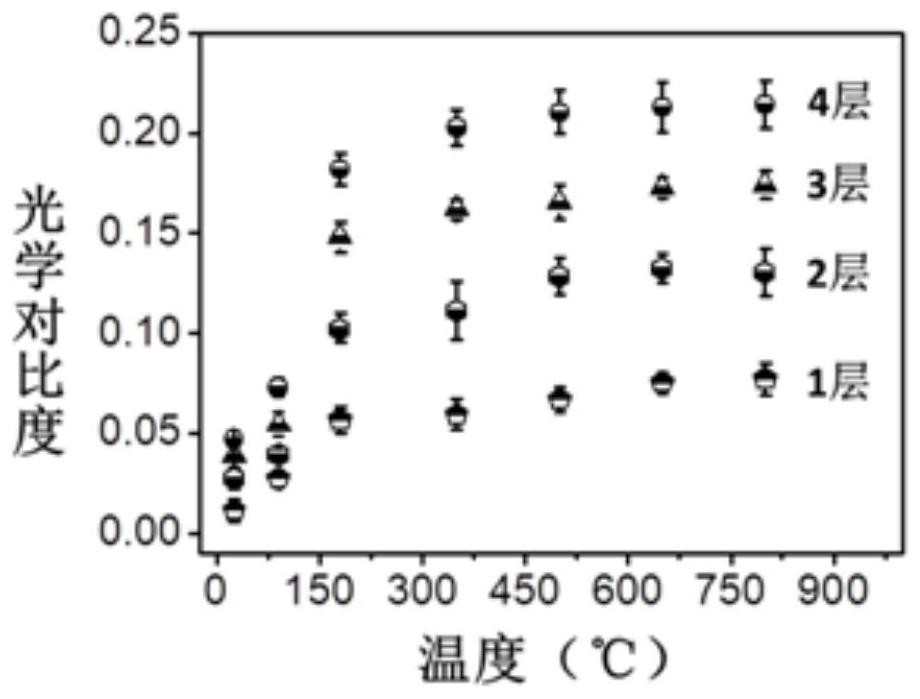

[0023] A method for determining the number of graphene oxide layers based on thermally enhanced optical contrast, the specific steps are as follows:

[0024] 1) Prepare the graphene oxide aqueous solution (2mg mL) required for sampling by the modified Hummers method -1 ), and then spin-coat the graphene oxide aqueous solution onto the pre-cleaned 285nm SiO 2 / Si substrate surface, SiO 2 / Si substrate is placed on the homogenizer, the speed of the homogenizer is set to 1000rpm, and the time is kept for 1min, so that the graphene oxide film dispersed in the graphene oxide aqueous solution is randomly adsorbed on the SiO 2 / Si substrate surface, dry naturally, obtain sample;

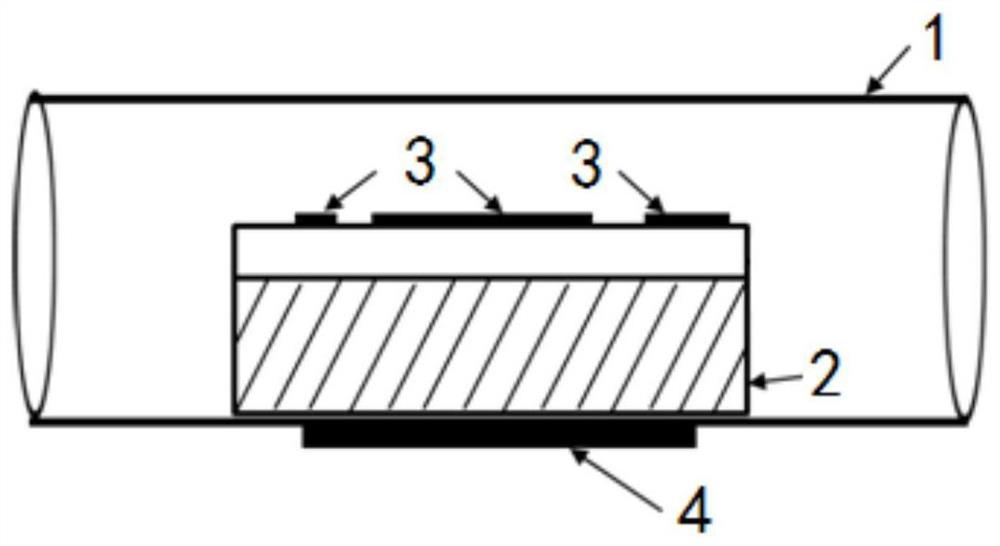

[0025] 2) Put the sample obtained in step 1) into a tube furnace (OTF-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com