Low-cost batch preparation method and application of noble metal electrode array

An electrode array, precious metal technology, applied in the direction of electrochemical variables of materials, etc., to achieve the effects of controllable thickness, wide application prospects and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

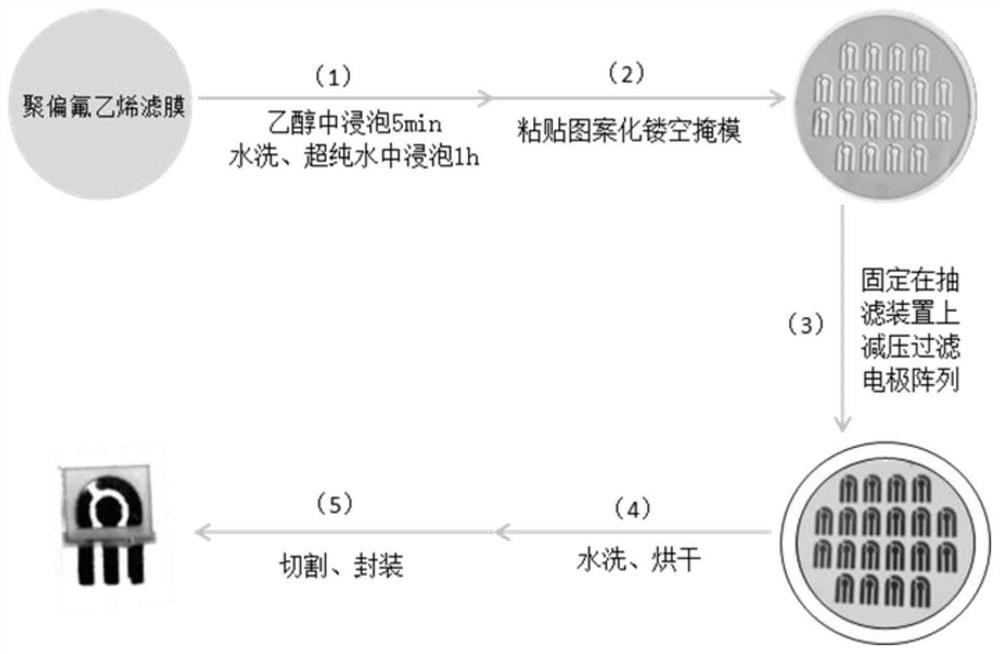

Method used

Image

Examples

Embodiment 1

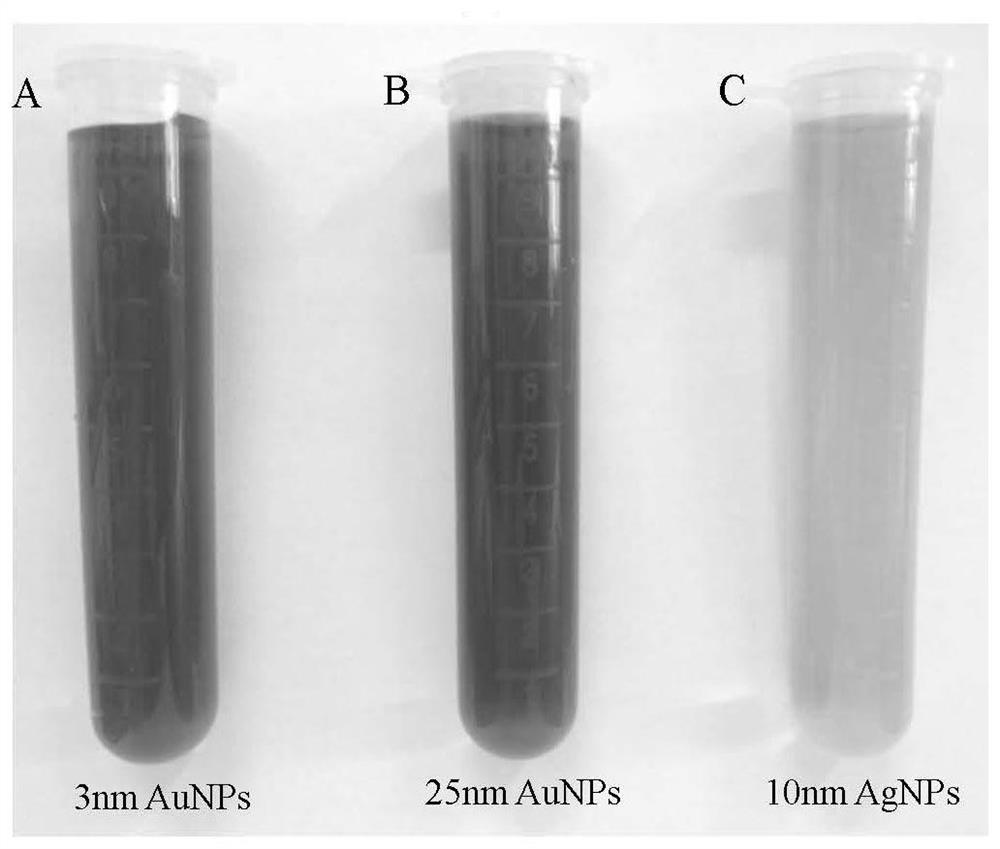

[0030] Use NaBH 4 Preparation of 3nm AuNPs solution by reduction method, including the following steps:

[0031] Add 5.5mL of 1wt% chloroauric acid solution into 495mL of ultrapure water and stir for 5min at room temperature; then add 11mL of 38.8mmol / L sodium citrate solution and stir for 3min at room temperature; finally add 5.5 mL of 0.075wt% NaBH prepared with 38.8mmol / L sodium citrate solution 4 solution, stirred at room temperature for 20min to prepare a 3nm AuNPs solution (such as figure 2 shown in A).

Embodiment 2

[0033] A 25nm AuNPs solution was prepared by a hydrothermal method, including the following steps:

[0034] With vigorous stirring, 4 mL of sodium citrate solution (1 wt%) was added to 100 mL of boiling HAuCl 4 In the aqueous solution (0.01wt%), the solution changed from colorless to dark purple; after that, continued to boil for 15min, and then stirred the solution until it was cooled to room temperature, that is, a 25nm AuNPs solution (such as figure 2 shown in B).

Embodiment 3

[0036] by NaBH 4 Preparation of 10nm AgNPs solution by reduction method includes the following steps:

[0037] To contain 0.01mol / L NaBH 4 and 140mL aqueous solution of 0.28mmol / L sodium citrate, add 40mL1.0mmol / L AgNO dropwise 3 solution, after a few drops, the colorless solution immediately turned into light yellow; after that, the prepared solution was continued to react for 48h at ambient temperature to obtain a 10nm AgNPs solution (such as figure 2 C shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com