Method for preparing electrochemical nano dot array electrode by using ultra-long nanowire

A nano-dot array and nano-wire array technology, applied in the direction of material electrochemical variables, nanotechnology for sensing, nanotechnology, etc., can solve the problems of high cost of processing equipment, poor size controllability, complicated process, etc. Achieve the effects of low processing cost, controllable size and shape, and simple instrument operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

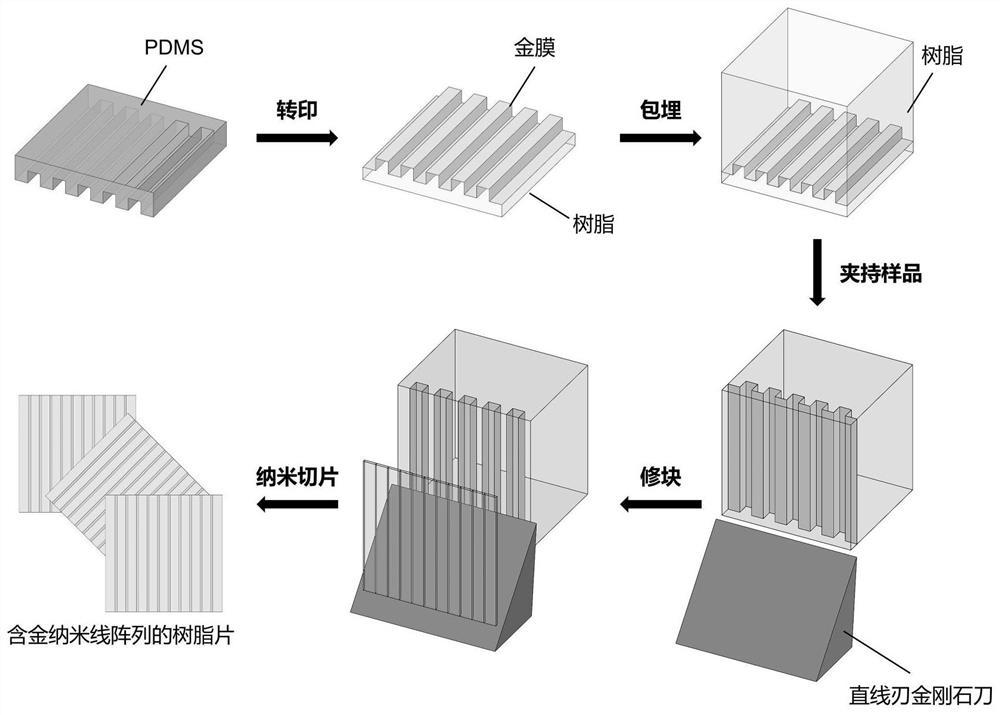

[0024] Specific implementation mode 1: This implementation mode records a method for preparing an electrochemical nano-dot array electrode by using ultra-long nanowires, and the steps of the method are:

[0025] Step 1: Pouring PDMS on a commercial silicon template containing micron groove arrays;

[0026] Step 2: pouring resin on the cured PDMS mold to obtain a resin block with a micron groove array;

[0027] Step 3: Deposit a layer of metal film on the resin block to obtain a metal-resin composite structure;

[0028] Step 4: Embedding the composite structure obtained in Step 3 with resin to obtain a resin-metal-resin embedding block;

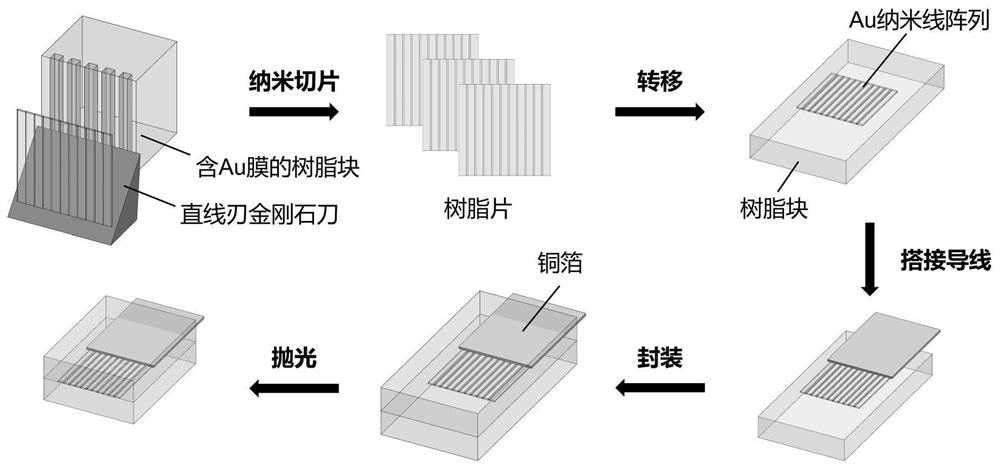

[0029] Step 5: Nano-slicing the embedding block obtained in Step 4 to obtain a resin sheet containing a nanowire array;

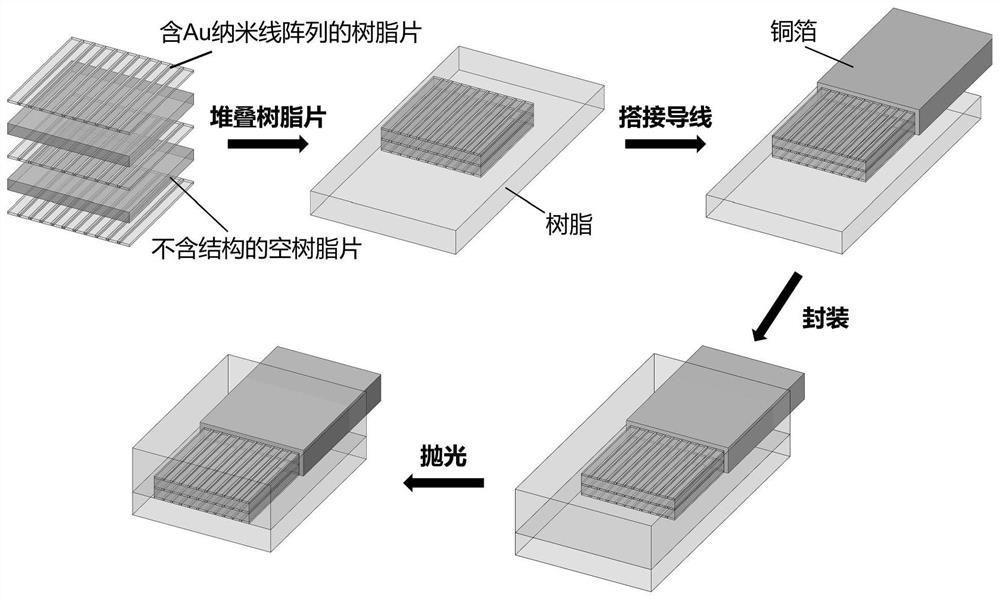

[0030] Step 6: transferring the single resin sheet containing nanowire arrays obtained in step 5 or multiple resin sheets containing nanowire arrays alternately stacked with empty resin sheets to a substrate to obtain a n...

specific Embodiment approach 2

[0033] Embodiment 2: In Embodiment 1, a method for preparing electrochemical nano-dot array electrodes by using ultra-long nanowires, in step 1, the metal thin film has a thickness of 2 nm to 1 μm.

specific Embodiment approach 3

[0034] Embodiment 3: In Embodiment 1 or 2, a method for preparing electrochemical nano-dot array electrodes by using ultra-long nanowires, in step 1, the metal is one of gold, platinum or silver.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com