Anode catalyst of direct borohydride fuel cell and preparation method thereof

A borohydride and fuel cell technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor catalytic activity and high price of hydrogen storage alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

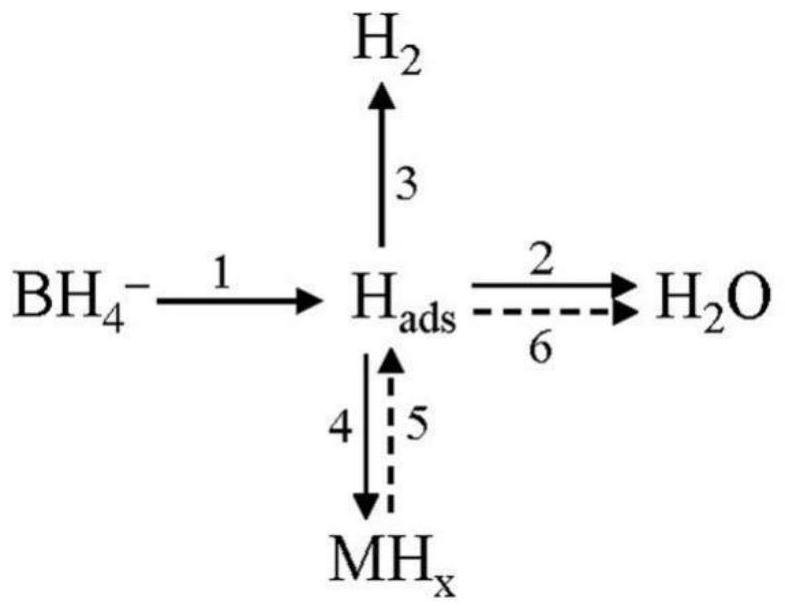

[0025] Reaction Mechanism of Hydrogen Storage Alloy as DBFC Anode Catalyst

[0026] like figure 1 Shown, BH 4 - During oxidation, BH 4 - The hydrogen is oxidized from negative valence to positive valence in two processes: first, BH 4 - The B-H bond is broken, and the negative one-valent hydrogen is oxidized to zero to generate surface-adsorbed hydrogen atoms H ads (Process 1), and then the surface adsorbs hydrogen atoms H ads Continue to be oxidized to positive monovalent (process 2), namely BH 4 - Direct oxidation process, corresponding to the reaction equation (Process 5)

[0027] BH 4 - +xOH - →BO 2 - +(x-2)H 2 O+(4-x)H 2 +xe - (process 5)

[0028] In the formula, x represents each BH in the actual reaction process 4 - The number of electrons released.

[0029] Second, the surface adsorbed hydrogen atoms H ads It is also possible to combine into H 2 Escape (process 3), this is BH4 - The side reaction (hydrolysis reaction) of the oxidation process co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com