Method for preparing corn juice by multistage cell disruption

A corn juice and cell technology, which is applied in the field of corn juice, can solve the problems such as difficulty in obtaining corn juice, and achieve the effects of being easy for human body to absorb, stable in color and luster, and preventing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The invention discloses a method for preparing corn juice by multistage cell wall breaking, which comprises the following steps:

[0047] Step one, beating;

[0048] Low-temperature ultrafine grinding of thawed and cleaned corn kernels;

[0049] Step 2. Ultrasonic wall breaking;

[0050] After mixing the crushed corn in step 1 according to the material-water ratio of 1:1-1:5 (g / mL), ultrasonic crushing for a certain period of time;

[0051] Step 3, enzymatic hydrolysis;

[0052] Firstly, α-amylase is added to the mixed solution in step 2 for enzymolysis, and α-amylase is enzymatically hydrolyzed alone for a period of time;

[0053] The β-glucanase is added to the mixed liquid hydrolyzed by the α-amylase, and the α-amylase and the β-glucanase cooperate to enzymatically hydrolyze for a period of time.

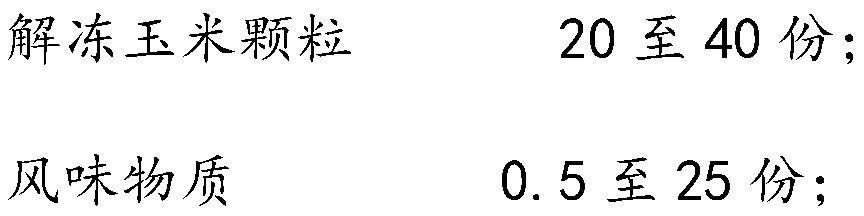

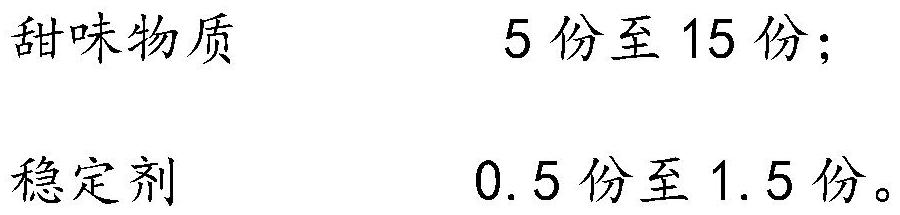

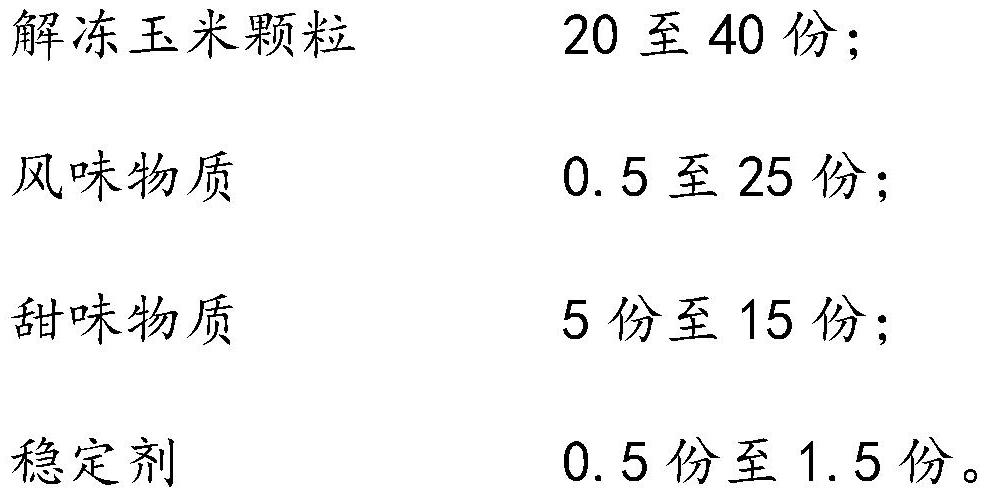

[0054] Step 4, mixing flavoring substances, sweeteners and stabilizers to obtain a mixed solution;

[0055]Step five, mixing and homogenizing;

[0056] Mix the mater...

Embodiment 2

[0068] The main difference between this embodiment and embodiment 1 is shown in table 1 and table 2;

[0069] The performance test parameters of the corn juice prepared in this embodiment are shown in Table 3.

Embodiment 3

[0071] The main difference between this embodiment and embodiment 1 is shown in table 1 and table 2;

[0072] The performance test parameters of the corn juice prepared in this embodiment are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com