Production method and application of lemon enzyme

A technology of lemon enzyme and lemon fruit, applied in the fields of application, function of food ingredients, food science, etc., can solve problems such as susceptibility to microorganisms, decreased enzyme activity, loss of enzyme activity, etc., to overcome activity decrease, low oxygen content, improve The effect of lemon fermentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

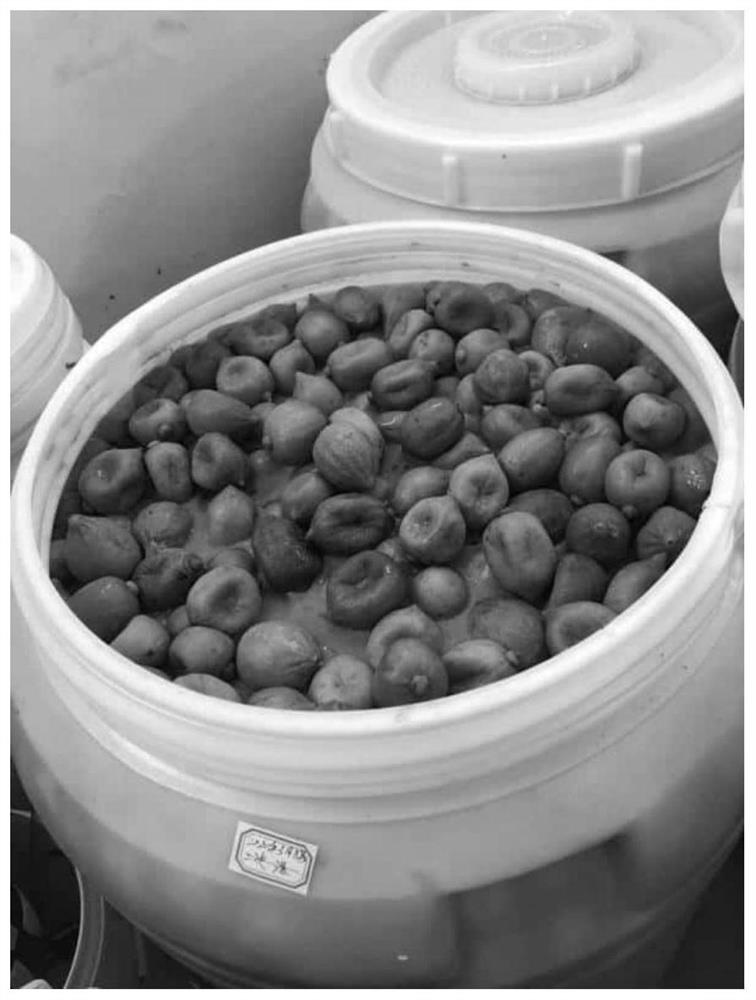

Image

Examples

Embodiment 1

[0028] A preparation method of lemon ferment, comprising the following steps:

[0029] (1) Take by weight 25 parts of fresh green lemon fruit with peel, 8 parts of white granulated sugar or rock sugar, and 90 parts of water and put them into a fermentation container at a temperature of 60°C for 30-50 minutes. Fermentation was carried out for 90 days to obtain lemon enzyme fermented liquid;

[0030] (2) Pasteurize the lemon enzyme fermented liquid prepared in step (1) at a temperature of 60° C. for 30 minutes, and then carry out precipitation for 80 days. During the precipitation period, pasteurize once every 40 days. Pasteurization conditions The temperature is 60°C, and the time is 40 minutes; after the precipitation is completed, a total of 2 pasteurizations are carried out.

[0031] (3) the lemon ferment fermented liquid after step (2) precipitation is clear and transparent yellow liquid, and pH value is 3.0-4.0, is 12000-13000mg / kg through detection lactic acid content, i...

Embodiment 2

[0034] A preparation method of lemon ferment, comprising the following steps:

[0035] (1) Weigh 30 parts by weight of fresh green lemon fruit with skin and 100 parts of water into a fermentation container at a temperature of 60°C for 1 pasteurization for 30-50 minutes, cool to room temperature naturally, and then transfer to the fermentation container Put 10 parts of white granulated sugar or rock sugar into the container, stir evenly, and ferment at room temperature for 90 days to obtain lemon enzyme fermented liquid;

[0036] (2) Pasteurize the lemon enzyme fermented liquid prepared in step (1) at a temperature of 60° C. for 40 minutes, and then carry out precipitation for 90 days. During the precipitation period, after every 30 days, pasteurization is carried out once. Pasteurization conditions The temperature is 60°C, and the time is 40 minutes; after the precipitation is completed, a total of 3 times of pasteurization are carried out.

[0037] (3) With embodiment 1 step...

Embodiment 3

[0039] A preparation method of lemon ferment, comprising the following steps:

[0040] (1) Take by weight 35 parts of fresh green lemon fruit with peel, 12 parts of white granulated sugar or rock sugar, and 110 parts of water and put them into a fermentation container at a temperature of 60°C for 30-50 minutes. Fermentation was carried out for 90 days to obtain lemon enzyme fermented liquid;

[0041] (2) Pasteurize the lemon enzyme fermented liquid prepared in step (1) at a temperature of 60° C. for 40 minutes, and then precipitate for 100 days. During the precipitation, pasteurize once every 20 days. Pasteurization conditions The temperature is 60°C, and the time is 40 minutes; after the precipitation is completed, a total of 5 times of pasteurization are carried out.

[0042] (3) With embodiment 1 step (3). The test results of the prepared finished products are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com