Efficient garden machine cleaning equipment and using method thereof

A technology for mechanical cleaning and gardening, which can be applied in the direction of cleaning methods using liquids, cleaning methods using tools, cleaning methods and utensils, etc., which can solve the problems of increased labor costs, large device size, and wide area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

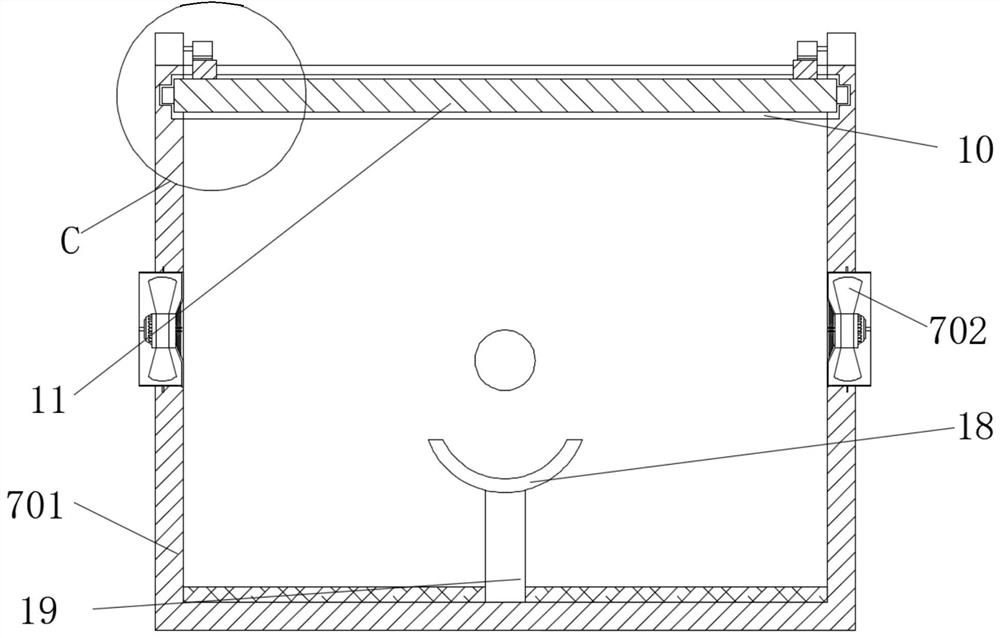

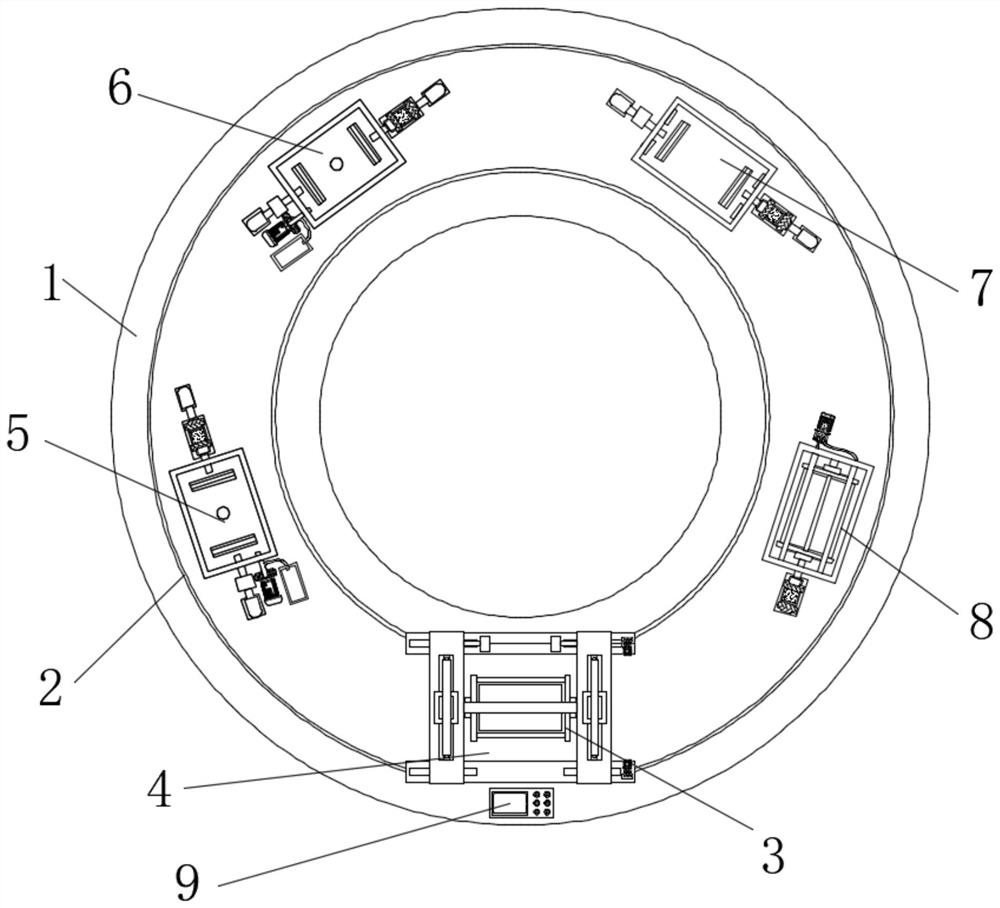

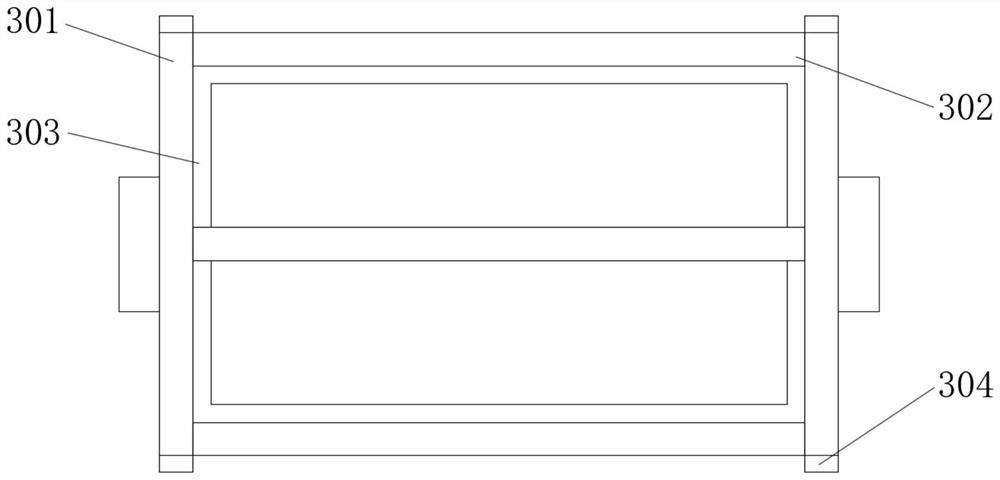

[0056] Embodiment one: if Figure 1-25 As shown, a high-efficiency garden machine cleaning equipment includes a workbench 1, and the top of the workbench 1 is equidistantly arranged in a clockwise direction with a moving device 4, a washing device 5, a flushing device 6, a drying device 7, and oiling and maintenance Device 8, washing device 5, rinsing device 6, drying device 7, oiling maintenance device 8 respectively comprise washing box 501, rinsing box 601, drying box 701, oiling box 801, washing box 501, rinsing box 601, drying The both sides inwalls of box 701, oiling tank 801 are all provided with chute 15, the side inwall of washing box 501, flushing box 601, drying box 701, oiling tank 801 are all provided with groove 10, the bottom inner wall of chute 15 The cover plate 11 is slidably connected, and the inner wall of the side where the two chute 15 are far away from each other is provided with a slide groove 16, and a plurality of equidistant rollers 17 are fixedly in...

Embodiment 2

[0070] Embodiment two: if Figure 26-27As shown, a high-efficiency garden machine cleaning equipment, the difference between this embodiment and the first embodiment is that: the center of the side of the two circular plates 809 close to each other is fixedly connected with the same stirring rod 813, and the two stirring rods 813 The ends respectively pass through the inner walls on both sides of the second circular metal frame 815 and are fixedly connected with the second circular metal frame 815. On the outer wall of the stirring rod 813, a plurality of equidistantly arranged hair brushes 814 are fixedly installed, and the hair brushes 814 are located at In the second circular metal frame 815, the stepper motor 817 drives the circular plate 809 and the second circular metal frame 815 to rotate, and the stirring rod 813 and the hair brush 814 rotate accordingly, and the hair brush 814 can efficiently and evenly clean the parts. Oil maintenance.

[0071] Working principle: op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com