High-yield amantadine preparation method

A high-yield technology for amantadine, applied in the field of high-yield amantadine preparation, can solve the problems of many by-products, waste of raw materials, low yield, etc., and achieve the effect of mild reaction and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

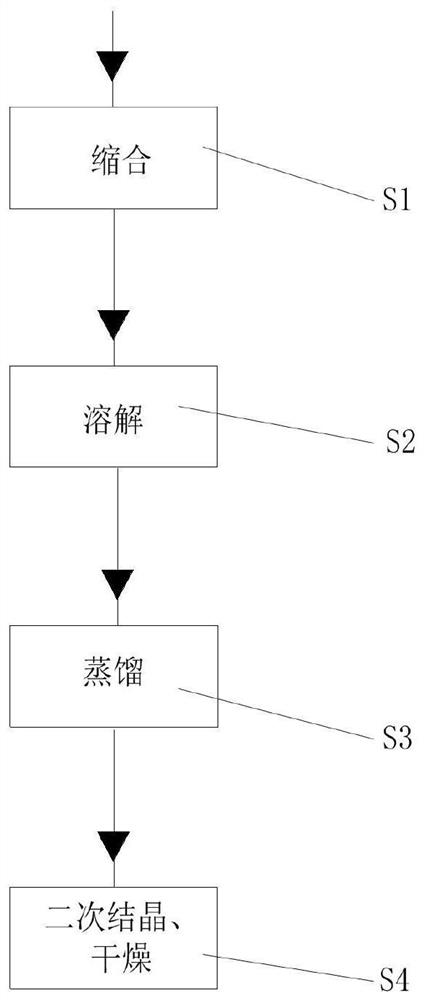

[0021] like figure 1 As shown, a method for preparing amantadine with high yield is as follows: condensation, bromination, urea and DMF are mixed and heated, and the solid is separated out and then kept warm; The solid was kept for 3 hours, and the mixed solution of water and DMF was continuously azeotropically distilled; distilled, an aqueous sodium hydroxide solution was prepared, added to the reactor in stages, and amantadine and water were azeotropically distilled; secondary crystallization, drying, Enter the plate and frame filter press to filter the finished product, and the yield of the finished product is 97.3%.

[0022] Specifically, in the S1 condensation step, after the materials are mixed and heated to 160-165°C, solids are precipitated, and the temperature is kept at 160-170°C for 1 hour;

[0023] Specifically, in the S2 dissolving step, the temperature is kept at 99-102° C. for 3 hours.

[0024] Specifically, the concentration of the sodium hydroxide aqueous so...

Embodiment 2

[0027] like figure 1 As shown, a method for preparing amantadine with high yield is as follows: condensation, bromination, urea and DMF are mixed and heated, and the solid is separated out and then kept warm; The solid was kept for 3 hours, and the mixed solution of water and DMF was continuously azeotropically distilled; distilled, an aqueous sodium hydroxide solution was prepared, added to the reactor in stages, and amantadine and water were azeotropically distilled; secondary crystallization, drying, Enter the plate and frame filter press to filter the finished product, and the yield of the finished product is 97.3%.

[0028] Specifically, in the S1 condensation step, after the materials are mixed and heated to 160-165°C, solids are precipitated, and the temperature is kept at 160-170°C for 1 hour;

[0029] Specifically, in the S2 dissolving step, the temperature is kept at 99-102° C. for 3 hours.

[0030] Specifically, the concentration of the sodium hydroxide aqueous so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com