Dual-phase-state wiping type stainless steel rust removal friction plate

A dual-phase wiping type and friction plate technology, which is applied to the types of brakes, mechanical equipment, brake parts, etc., can solve the problems of thick pickling in the rusted area and insufficient, so as to reduce excessive waste, reduce the possibility, The effect of improving the wiping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

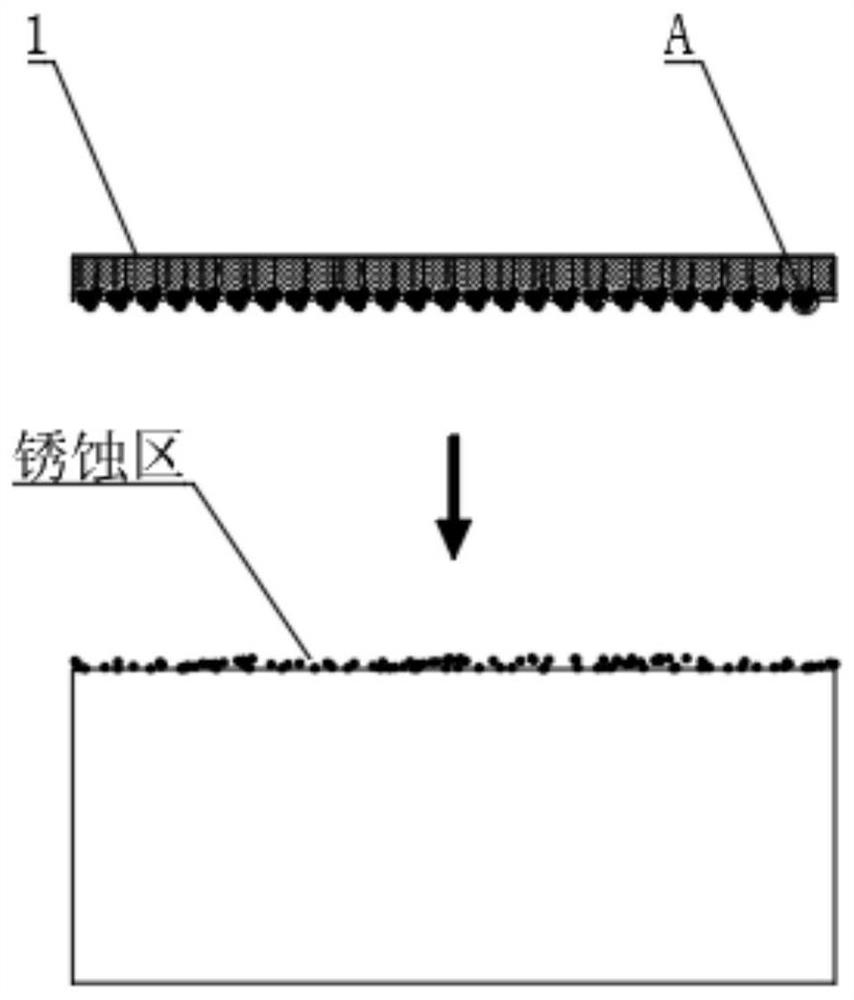

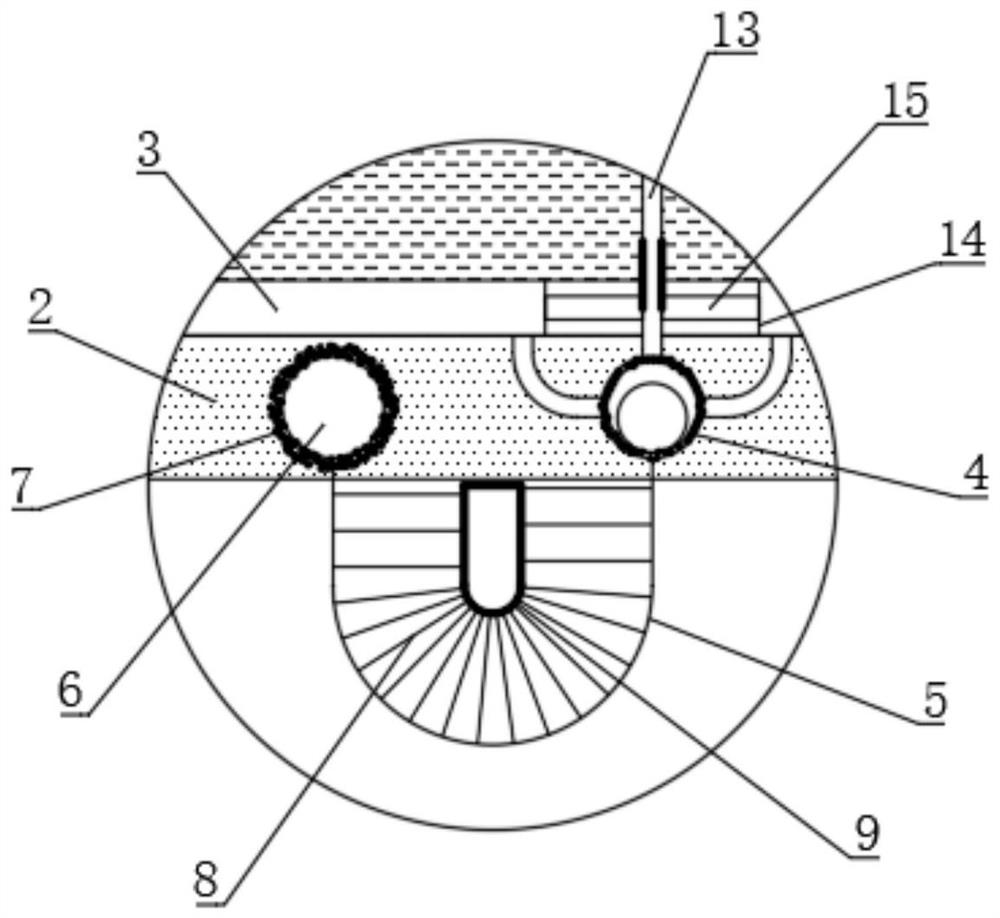

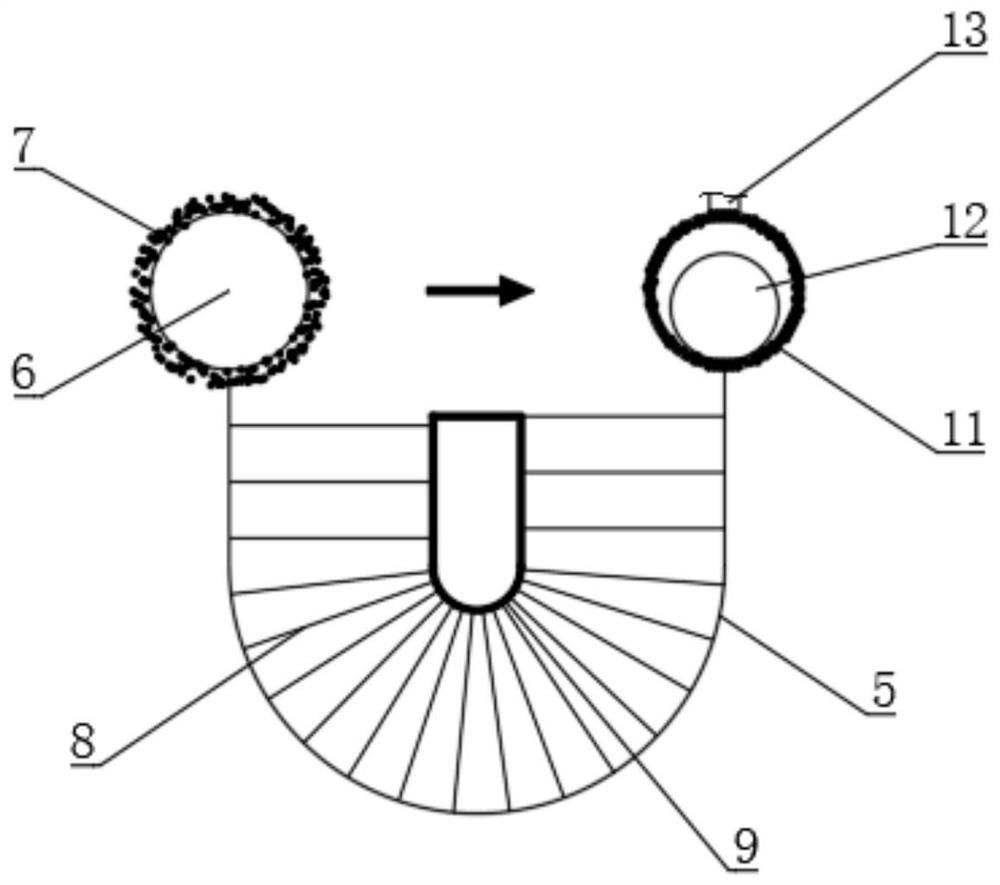

[0044] see Figure 1-4 , a dual-phase wiping type stainless steel rust removal friction plate, comprising a pickling friction plate 1, the pickling friction plate 1 includes a pre-protection layer 2, the upper end of the pre-protection layer 2 is fixedly connected with an upper storage bag frame 3, and the upper storage The bottom end of the package frame 3 is fixedly connected with a plurality of evenly distributed magnetic variable balls 4 embedded in the pre-protection layer 2. The bottom end of the fixed magnetic variable balls 4 is fixedly connected with a U-shaped elastic rope 5, and the U-shaped elastic rope 5 is away from the One end of the fixed magnetic variable ball 4 is fixedly connected to the dynamic traction ball 6 embedded in the pre-protection layer 2, the outer end of the dynamic traction ball 6 is fixedly connected with a plurality of evenly distributed reaction powder layers 7, and the outer end of the U-shaped elastic rope 5 A plurality of uniformly distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com