Vacuum tube solar water heater achieving convection heat exchange and control method of vacuum tube solar water heater

A technology for solar water heaters and convective heat transfer, applied to solar collector controllers, solar collectors using working fluids, solar collectors, etc., can solve the problems of small water flow space, shaking, and low average temperature of water tanks problems, to achieve the effect of improving convective heat transfer efficiency, improving connection stability, and accelerating heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

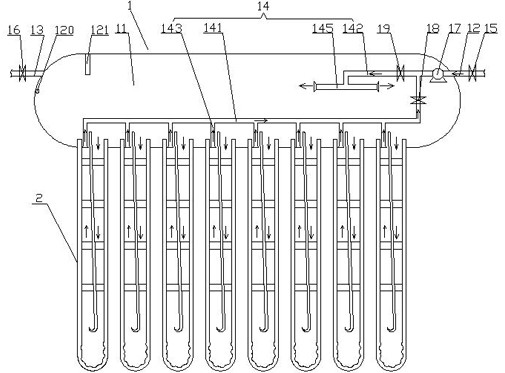

[0035] like figure 1 An embodiment of a convective heat exchange vacuum tube solar water heater of the present invention is shown, including a water tank 1 and a plurality of vacuum tubes 2 communicated with the water tank 1, and the plurality of vacuum tubes 2 are arranged in parallel and correspondingly;

[0036] The water tank 1 includes a box body 11, a water inlet pipe 12 placed on one side of the box body 11, and a water outlet pipe 13 placed on the other side of the box body 11. One end of the water inlet pipe 12 is connected with a circulation assembly 14, and the circulation assembly 14 includes a water inlet pipe. 12 communicated first pipeline 141, second pipeline 142; on the first pipeline 141, branch pipe 143 is extended to the open end of the hot water tank 26 of a plurality of vacuum tubes 2 respectively; A first water outlet pipe 144 extends vertically on one side and a second water outlet pipe 145 extends vertically to the other side;

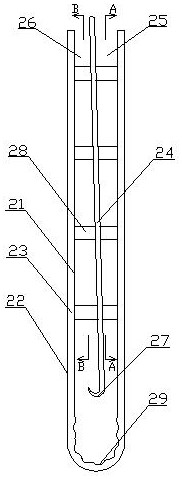

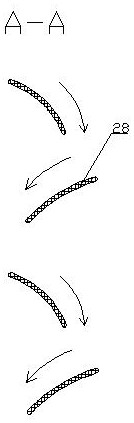

[0037] like figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com