High-capacity and long-cycle nickel-cobalt-manganese ternary positive electrode material and preparation method thereof

A positive electrode material and long-cycle technology, applied in electrical components, battery electrodes, electrochemical generators, etc., can solve the problem that the ternary nickel-cobalt-manganese positive electrode material cannot take into account the best capacity and cycle performance at the same time, and achieve good cycle performance , Improve crystallinity, increase the effect of material capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

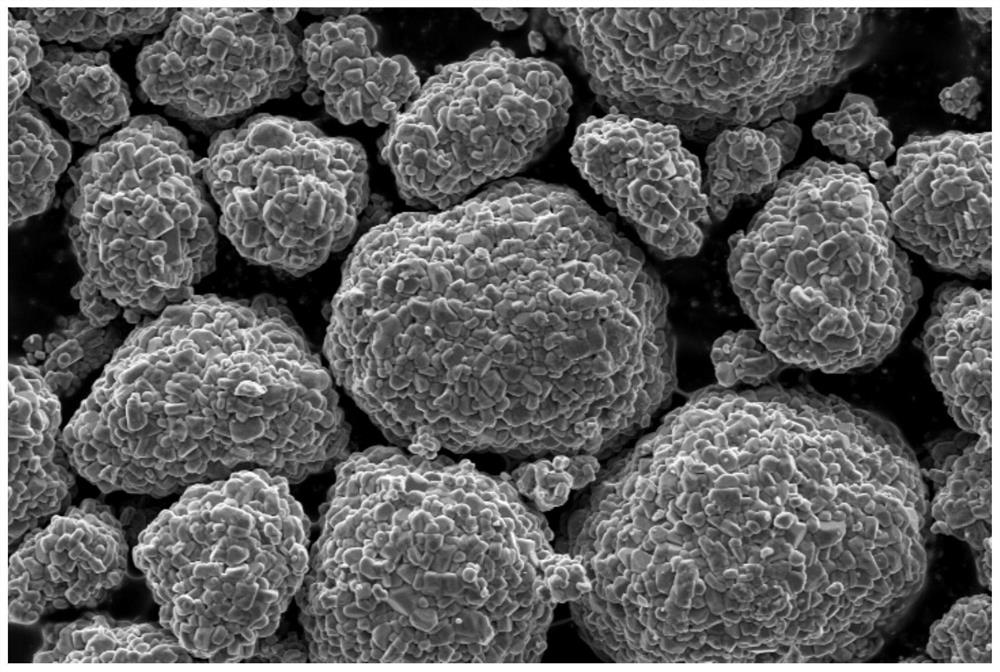

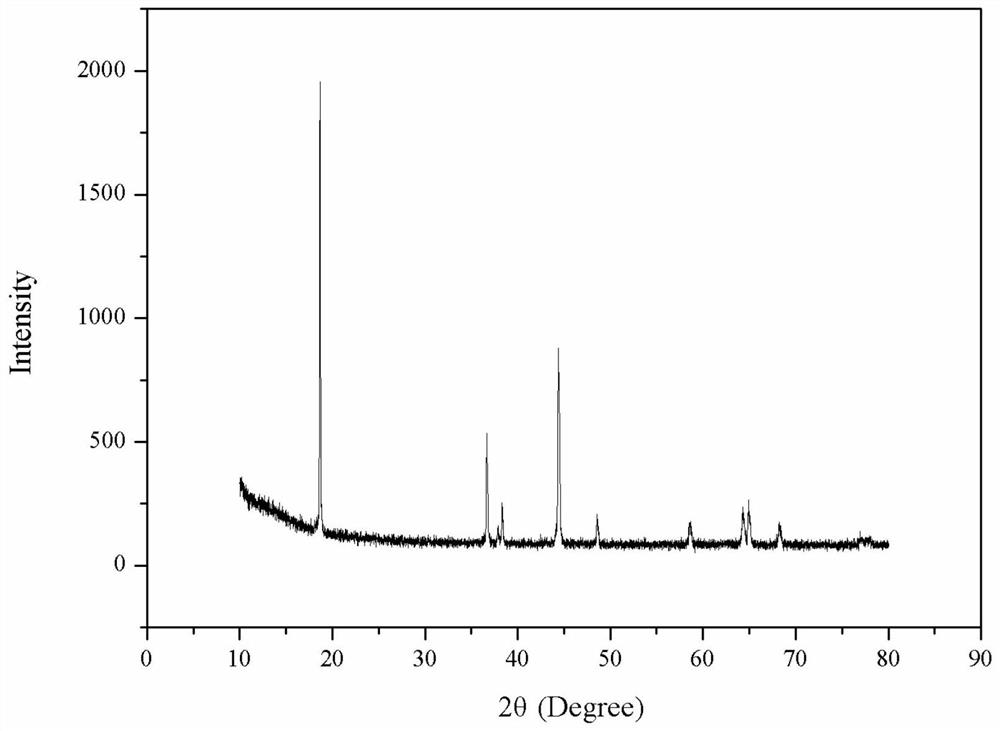

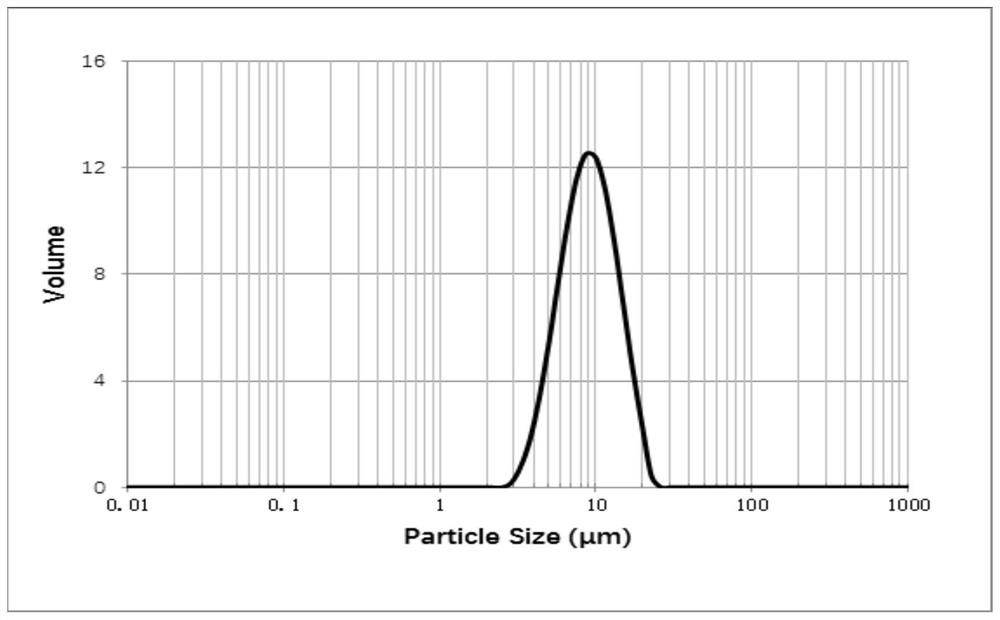

[0035] A kind of high capacity of the present invention, long cycle nickel-cobalt-manganese ternary cathode material (LiNi 0.52 co 0.20 mn 0.28 o 2 ), the grain size is 255.1nm, the residual stress is 0.220 after X-ray diffraction test and refinement, and the D50 of the ternary cathode material is 9.4μm.

[0036] The preparation method of the high-capacity, long-cycle ternary nickel-cobalt-manganese cathode material of this embodiment is as follows:

[0037] (1) According to the ratio of nickel-cobalt-manganese precursor (D50 is 9.5μm) and lithium metal in lithium carbonate as 1:1.04, weigh 4.8kg of ternary precursor Ni 0.52 co 0.20 mn 0.28 (OH) 2 With 2.2kg lithium carbonate;

[0038] (2) Add the material weighed in step (1) into a small-scale high-speed mixer, first mix the materials at a speed of 500 rpm for 5 minutes, and then mix the materials at a speed of 1000 rpm for 15 minutes;

[0039] (3) Carry out insulation and high-temperature sintering with the mixture o...

Embodiment 2

[0042]A kind of high capacity of the present invention, long cycle ternary cathode material (LiNi 0.52 co 0.20 mn 0.28 o 2 ), the grain size of the ternary cathode material is 282nm, the residual stress after X-ray diffraction test and refinement is 0.229, and the D50 of the ternary cathode material is 9.6μm.

[0043] The preparation method of this example is basically the same as Example 1, the only difference is that the high-temperature sintering temperature of the second stage of step (3) is different. The sintering procedure of step (3) of this example is: room temperature→500°C / 4h→ 700°C / 2h→890°C / 6h→880°C / 8h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com