High-capacity high-stability silicon-carbon composite nano material for lithium battery electrodes

A composite nanomaterial, high stability technology, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc. characteristics, improved lithium storage performance, optimal capacity and stable cycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

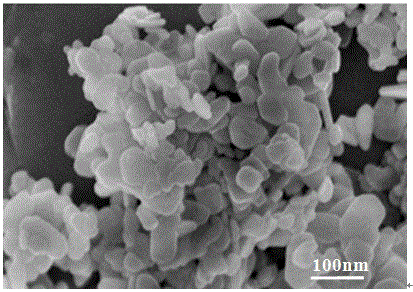

Image

Examples

Embodiment 1

[0026] A method for preparing a high-capacity lithium battery electrode silicon-carbon composite nanomaterial, comprising the following steps

[0027] step:

[0028] (1) Preparation of porous silicon matrix: Mix ethanol and ethyl orthosilicate at a molar ratio of 10:1 at room temperature, add 0.6mol / L hydrochloric acid aqueous solution dropwise under stirring, hydrochloric acid and ethyl orthosilicate The molar ratio is 0.2:1. After the dropwise addition, the mixed solution A is obtained by constant temperature reaction. The reaction temperature is 40°C and the reaction time is 1.5 hours; Take sodium silicate and make it into an aqueous solution of sodium silicate. Add ammonia aqueous solution dropwise to the aqueous sodium silicate solution under stirring. The molar ratio of ammonia water to sodium silicate is 0.05:1. After the addition, keep the temperature at 50°C for 2 Mixed solution B was obtained after 1 hour; then the mixed solution A and mixed solution B were aged for...

Embodiment 2

[0032] A method for preparing a high-capacity lithium battery electrode silicon-carbon composite nanomaterial, comprising the steps of:

[0033] (1) Preparation of porous silicon matrix: Mix ethanol and methyl orthosilicate at a molar ratio of 20:1 at room temperature, add 0.25mol / L sulfuric acid aqueous solution dropwise under stirring, sulfuric acid and methyl orthosilicate The molar ratio of the solution is 0.05:1. After the dropwise addition, the mixed solution A is obtained by constant temperature reaction. The reaction temperature is 60°C and the reaction time is 1 hour; the molar ratio of potassium silicate to methyl orthosilicate is 3:1. Take potassium silicate and prepare potassium silicate aqueous solution. Add ammonia aqueous solution dropwise to potassium silicate aqueous solution under stirring. The molar ratio of ammonia water to potassium silicate is 0.05:1. Mixed solution B was obtained in 1 hour; then the mixed solution A and mixed solution B were aged for 20 ho...

Embodiment 3

[0037] A method for preparing a high-capacity lithium battery electrode silicon-carbon composite nanomaterial, comprising the steps of:

[0038] (1) Preparation of porous silicon matrix: Mix ethanol and polysiloxane at a molar ratio of 30:1 at room temperature, add 0.3mol / L nitric acid aqueous solution dropwise under stirring, nitric acid and polysiloxane The molar ratio is 0.06:1, after the dropwise addition is completed, the constant temperature reaction obtains the mixed solution A, the reaction temperature is 70°C, and the reaction time is 2 hours; the molar ratio of metasilicon tetrachloride to polysiloxane is 3: 1 Weigh the partial tetrachloride silicon, and prepare the partial tetrachloride aqueous solution, drop the sodium hydroxide aqueous solution in the partial tetrachloride aqueous solution under stirring state, the molar ratio of sodium hydroxide and partial tetrachloride The ratio is 0.06:1, and after the addition is completed, the temperature is kept at 50°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com