Software robot, preparation method thereof, passive robot communication network, and application

A communication network and robot technology, applied in the field of soft robot communication, can solve the problems that soft robots are difficult to communicate, and achieve the effect of simple structure, high adaptability and great development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The embodiment of the present invention also provides a method for preparing the above-mentioned soft robot. The method for preparing the soft robot includes the following steps:

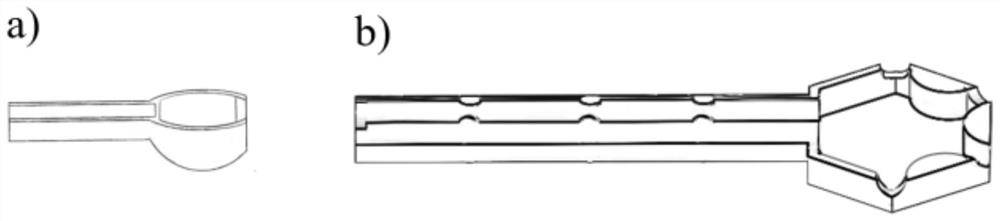

[0052] 1) The conductive copper wire is made into a conductive coil by physical winding, and then the conductive coil is placed in the first packaging mold, and the liquid silicone resin Ecoflex (that is, the aliphatic aromatic random copolyester manufactured by BASF Company of Germany) Ecoflex) or liquid dimethyl siloxane to fix the conductive coil, solidify, and release the mold to obtain the synapse 1;

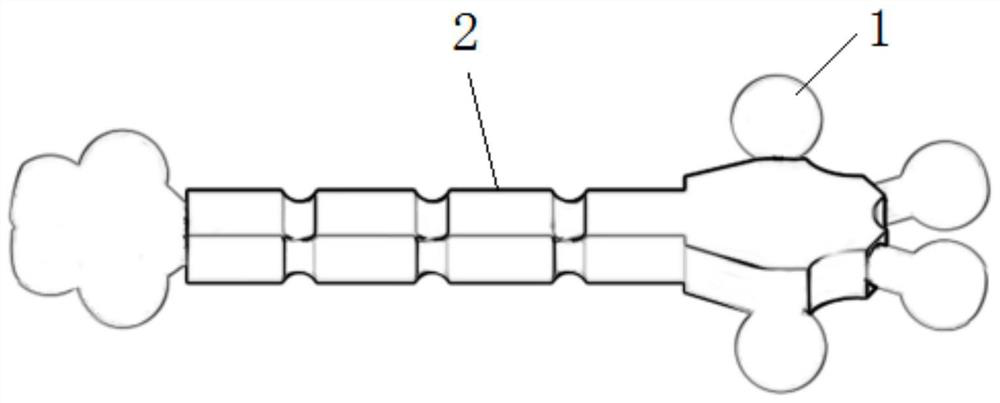

[0053] 2) Place the prepared 2n (wherein n is a natural number) synapse 1 pairwise into the second packaging mold, which will contain Nd 2 Fe 14 The mixture of B (NdFeB) magnetic powder is injected into the second encapsulation mould, solidified, and demoulded to obtain a semi-finished product;

[0054] 3) Folding the main body 2 of the semi-finished product into multiple sections, placi...

Embodiment 1

[0071] (1) The conductive copper wire was made into a conductive coil with a radius of 3 mm by physical winding, and then the conductive coil was placed in the 3D printed packaging mold I and fixed with liquid silicone resin Ecoflex (T605#A&B), 80 Curing at ℃ for 1 h; after demoulding, synapses were obtained.

[0072] (2) After connecting the eight synapses in pairs, place them in the 3D printed encapsulation mold II. Nd with an average size of 5 μm 2 Fe 14B The magnetic powder and the viscous Ecoflex liquid are mixed according to the mass ratio of 1:1, and after stirring evenly, inject it into the packaging mold II. Curing at 70°C for 2 hours, and after demoulding, a soft robot is obtained.

[0073] (3) The prepared soft robot is folded into three sections, and placed in a magnetizer for vertical magnetization. At high voltage (500V), Nd 2 Fe 14 B particles are instantly magnetized to saturation within 3s. After magnetization, there are opposite magnetic poles inside t...

Embodiment 2

[0076] (1) The conductive copper wire is made into a conductive coil with a radius of 4.5mm by physical winding, and then the conductive coil is placed in the 3D printed packaging mold I and fixed with a liquid dimethyl siloxane precursor, Curing at 60°C for 3 hours; after demoulding, synapses were obtained.

[0077] (2) After connecting the eight synapses in pairs, place them in the 3D printed encapsulation mold II. Nd with an average size of 50 μm 2 Fe 14 B The magnetic powder and the viscous Ecoflex liquid are mixed according to the mass ratio of 9:1, stirred evenly, and injected into the packaging mold II. Curing at 50°C for 3 hours, after demoulding, a soft robot is obtained.

[0078] (3) The prepared soft robot is folded into three sections, and placed in a magnetizer for vertical magnetization. At high voltage (1000V), Nd 2 Fe 14 B particles are instantly magnetized to saturation within 2s. After magnetization, there are opposite magnetic poles inside the robot, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com