Photo-thermal evaporation and waste heat recovery integrated device and application thereof

A waste heat recovery and evaporating body technology, which is applied in general water supply conservation, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of difficult collection of condensed water, loss of steam waste heat, blocking incident light, etc. Light blocking problem, guaranteed stability, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

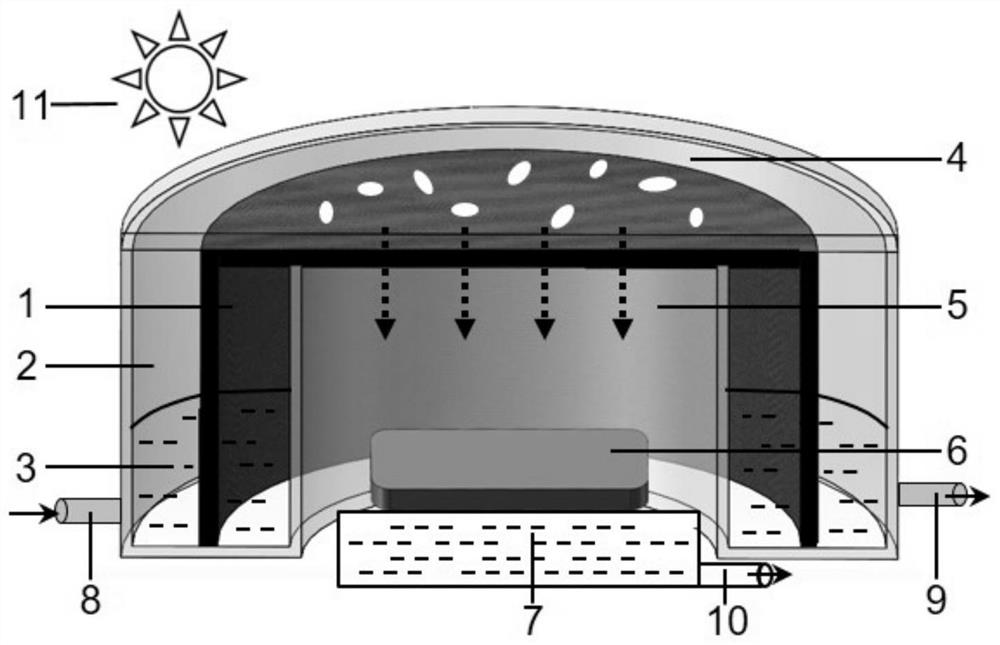

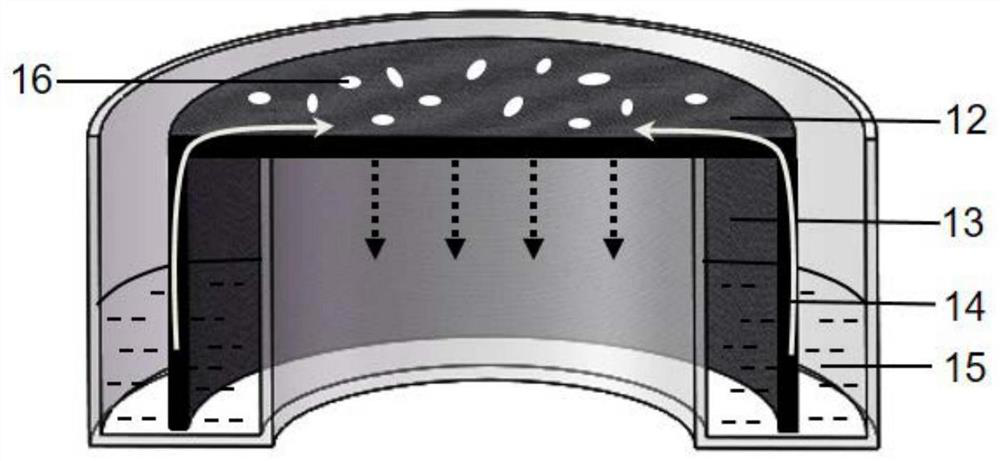

[0034] Such as figure 1 , figure 2As shown, the photothermal evaporation and waste heat recovery integrated device provided by the present invention includes: photothermal evaporation body 1, evaporation chamber 2, water supply pool 3, light-transmitting plate 4, condensation heat storage chamber 5, thermoelectric power generation element 6, condensation Pool 7, feed water inlet 8, feed water outlet 9, condensed water outlet 10, sunlight 11. Wherein, the photothermal evaporating body is carbonized bamboo tube, the light absorbing body 12 and the heat insulator 13 form the photothermal evaporating body 1, the light absorbing body 12 is a carbonized bamboo node, and the heat insulating body 13 is a carbonized bamboo wall.

[0035] Such as figure 1 , figure 2 , the feed water is injected into the water supply pool 3 through the feed water inlet 8; the photothermal evaporator 1 is placed in the evaporation chamber 2; the evaporation chamber 2 surrounds the condensation heat s...

Embodiment 2

[0047] The photothermal evaporation and waste heat recovery integrated device used in this embodiment is as described in Embodiment 1, wherein the Seebeck coefficient of the thermoelectric power generation element 6 is 10 mV K -1 The height of the condensation heat storage chamber 5 is 6cm; the preparation method of the photothermal evaporator 1 is as follows:

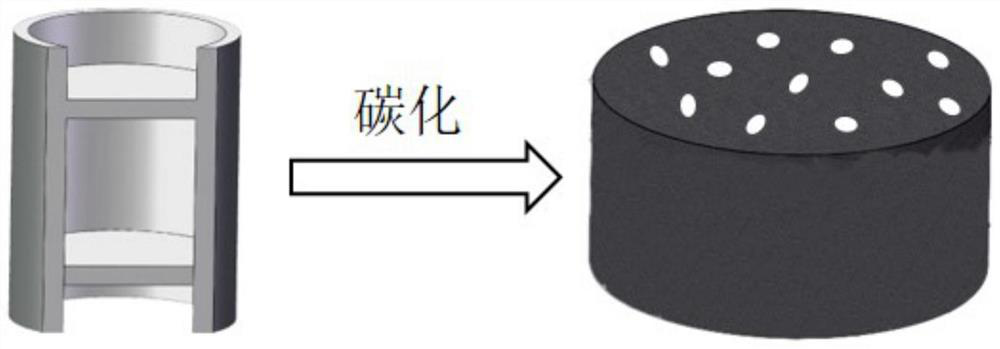

[0048] 1. Take the bamboo joints as the incision, cut the bamboo into small bamboo tubes, and keep the bamboo joints and a certain length of bamboo wall;

[0049] 2. Remove the bamboo skin on the surface of the bamboo tube, wash it with deionized water, and then dry it at 100°C for 10 hours under the protection of nitrogen;

[0050] 3. Put the dried bamboo tube into a tube furnace, and under the protection of nitrogen, carbonize at 500°C for 20 minutes to obtain carbonized bamboo tube.

[0051] The performance test results of this embodiment are shown in Table 1.

Embodiment 3

[0053] The photothermal evaporation and waste heat recovery integrated device used in this embodiment is as described in Embodiment 1, wherein the Seebeck coefficient of the thermoelectric power generation element 6 is 7 mV K -1 The height of the condensation heat storage chamber 5 is 4cm; the preparation method of the photothermal evaporator 1 is as follows:

[0054] 1. Take the bamboo joints as the incision, cut the bamboo into small bamboo tubes, and keep the bamboo joints and a certain length of bamboo wall;

[0055] 2. Remove the bamboo skin on the surface of the bamboo tube, wash it with deionized water, and then dry it at 93°C for 7 hours under the protection of nitrogen;

[0056] 3. Put the dried bamboo tube into a tube furnace, under the protection of nitrogen, carbonize at 430°C for 17 minutes to obtain carbonized bamboo tube

[0057] The performance test results of this embodiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com