Reversible proton ceramic battery electrode material and preparation method and application thereof

An electrode material, air electrode technology, applied in battery electrodes, electrodes, fuel cells, etc., to achieve the effects of excellent performance, optimized ion and electron transport paths, excellent proton transport and ion phase diffusion capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

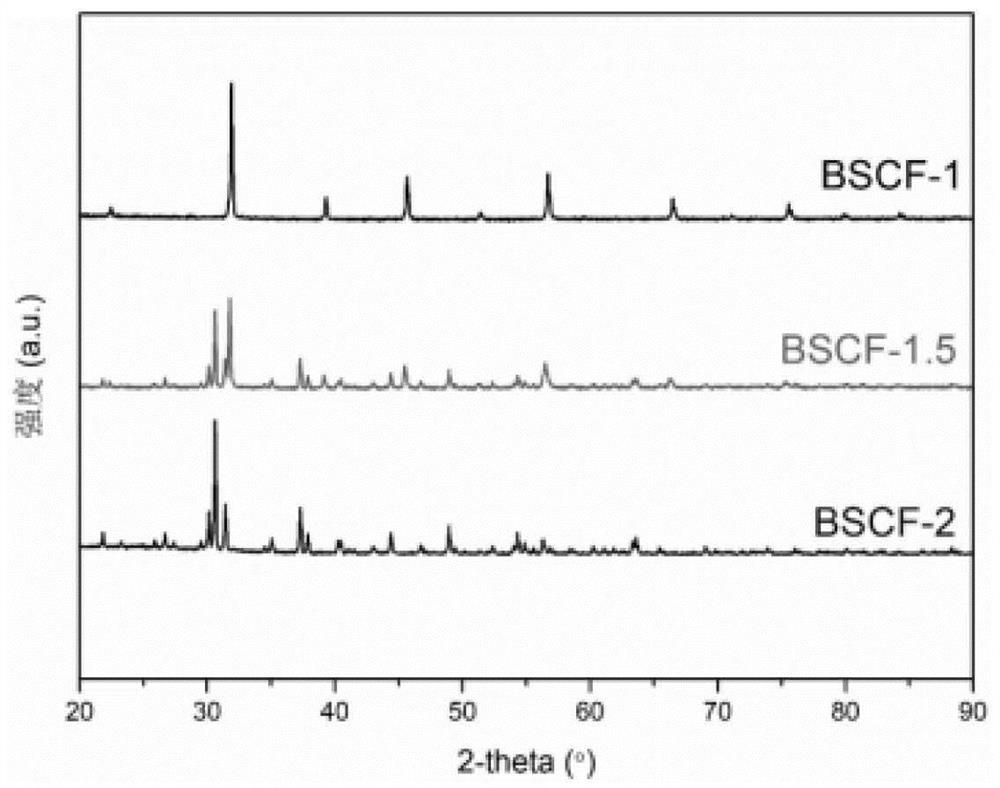

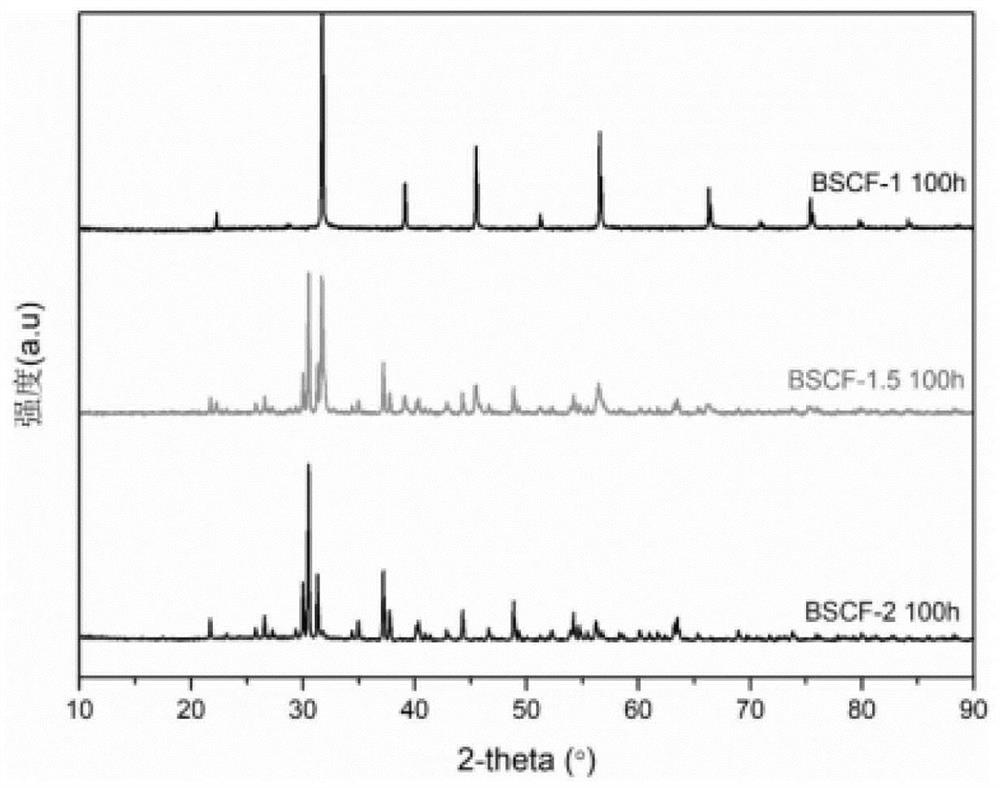

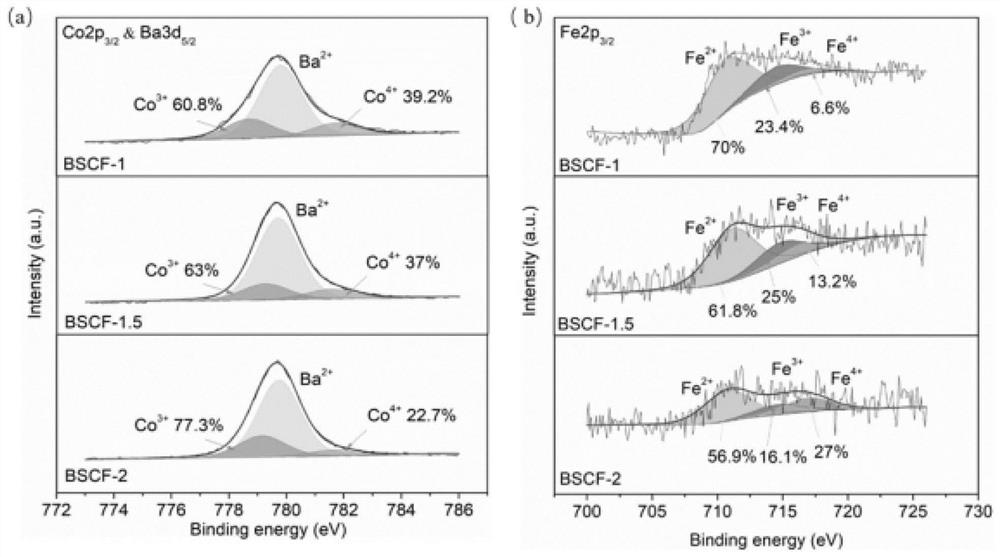

[0062] The invention provides a high-performance air electrode material Ba of a proton conductor fuel cell / electrolyzer 0.75 Sr 0.75 co 0.8 Fe 0.2 o 4-δ (BSCF-1.5) and its preparation method and application, wherein δ represents the content of oxygen vacancies, belonging to the technical field of reversible solid oxide batteries. One-step synthesis of biphasic electrode BSCF-1.5 by sol-gel method, in which the composition of the two phases is Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ (BSCF-1) and BaSrCo 0.8 Fe 0.2 o 4-δ (BSCF-2). Among them, BSCF-1 provides high electronic conductivity, and the high content of Co can better maintain the proton conductivity of the parent material double perovskite structure, and make the material have excellent conductivity and catalytic activity; while Fe Elements can also improve the electrical conductivity and catalytic activity of the host material, and on the other hand, further improve the structure and electrochemical stability of th...

Embodiment 1

[0064] Low temperature proton ceramic fuel cell / electrolyzer air electrode material Ba in embodiment 1 0.75 Sr 0.75 co 0.8 Fe 0.2 o 4-δ preparation of

[0065] (1) Weigh 9.8007g of barium nitrate, 7.9362g of strontium nitrate, 11.6412g of cobalt nitrate, 4.04g of iron nitrate, add a small amount of deionized water to dissolve. Weigh 11.7 g of EDTA and 16.8 g of citric acid hydrate as a complexing agent and dissolve them in deionized water at a molar ratio of EDTA: citric acid monohydrate: total metal ions of 1:2:1.

[0066] (2) After adding the solution containing complexing agent to the solution containing metal ions, add an appropriate amount of ammonia water dropwise to make the pH of the solution reach between 7 and 8, and then stir under the condition of magnetic stirring to completely evaporate the water to obtain a gel substance.

[0067] (3) The gel-like substance was placed in an oven and calcined at 250° C. for 5 hours to obtain the desired foamy precursor.

...

Embodiment 2

[0069] Embodiment 2 Preparation of symmetrical battery

[0070] (1) Take by weighing the cathode powder Ba obtained in 1g embodiment 1 0.75 Sr 0.75 co 0.8 Fe 0.2 o 4-δ , 10ml of isopropanol, 2ml of ethylene glycol, and 0.8ml of glycerin are poured into the high-energy ball mill, and after ball milling for 30min under the condition of 400r / min, the required cathode slurry is obtained after being transferred to the strain bottle with a straw .

[0071] (2) Place the prepared BZCYYb electrolyte on a heating table to preheat at 200°C, use a spray gun to spray the prepared cathode slurry evenly on both sides of the electrolyte under the push of an inert gas, and wait until the liquid is completely volatilized, The sprayed electrolyte was placed in a high-temperature muffle furnace and calcined at 1000°C for 2 hours to prepare the required symmetrical battery, which was used for the test of the polarization resistance of the cathode material in the temperature range of 500-700°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| open-circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com