Preparation method of novel lithium ion battery negative electrode material niobium-based oxide

A lithium-ion battery and negative electrode material technology, applied in the direction of niobium compounds, battery electrodes, chemical instruments and methods, etc., can solve the problems of complex process, high synthesis temperature, high equipment requirements, etc., to improve electrochemical performance, increase electrical conductivity, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

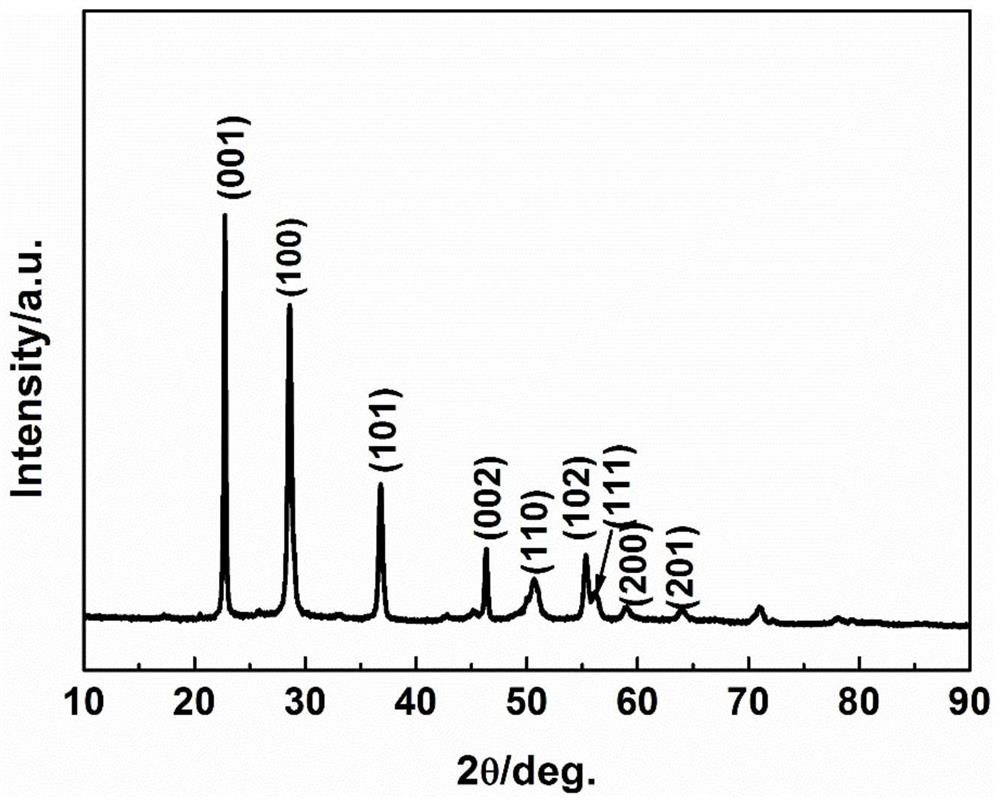

[0021] Example 1: Weigh niobium powder, selenium powder, copper powder and tungsten powder according to the stoichiometric ratio, the excess selenium is 6%, and the molar ratio of tungsten and niobium is 1:23.6. Add a certain amount of absolute ethanol, the solid-to-liquid ratio is 0.3:1. The material was heated in a water bath at 35° C. for 4 hours under electromagnetic stirring, and ultrasonically dispersed for 30 minutes. After completion, the material was dried in a blast drying oven. Subsequently, the material was wet-milled for 7 hours, and the ball milling speed was n=350r / min. After the ball milling and dispersion were completed, the ball mill jar was placed in an oven for drying. Then placed in an argon atmosphere and sintered at 700 °C for 5 h to obtain the precursor Cu 2 W 0.05 Nb 0.78 Se 4 material, the heating rate is 10°C / min. Precursor Cu 2 W 0.05 Nb 0.78 Se 4 The material is placed in a glass tube in the air state and calcined at 600 ° C for 6 hours to...

Embodiment 2

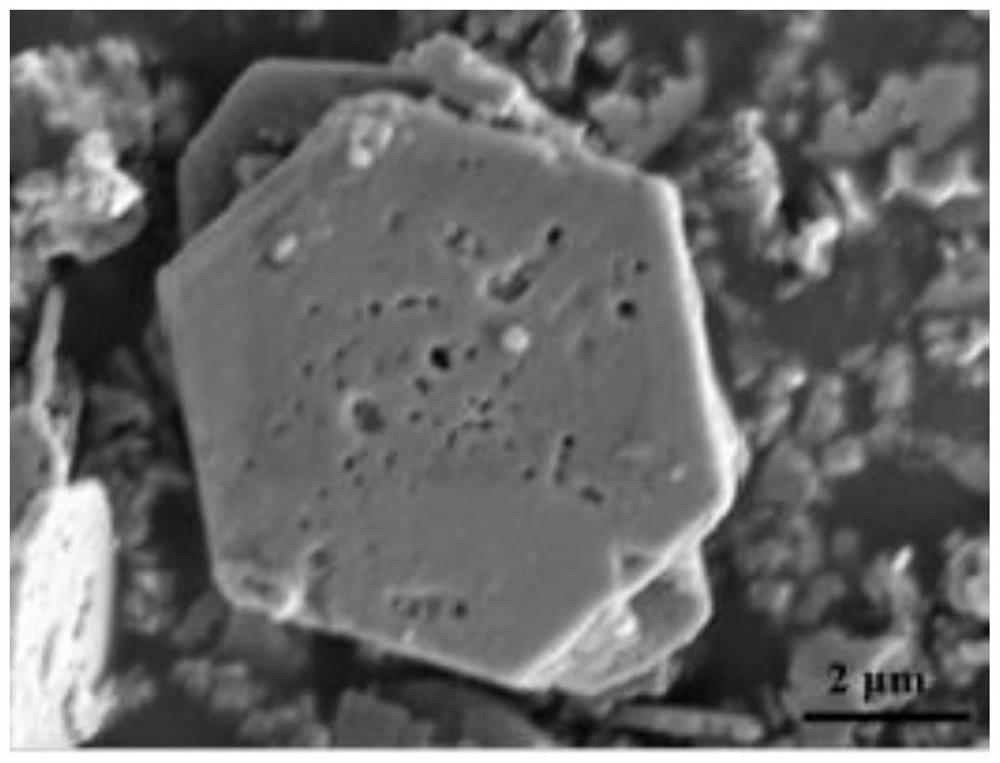

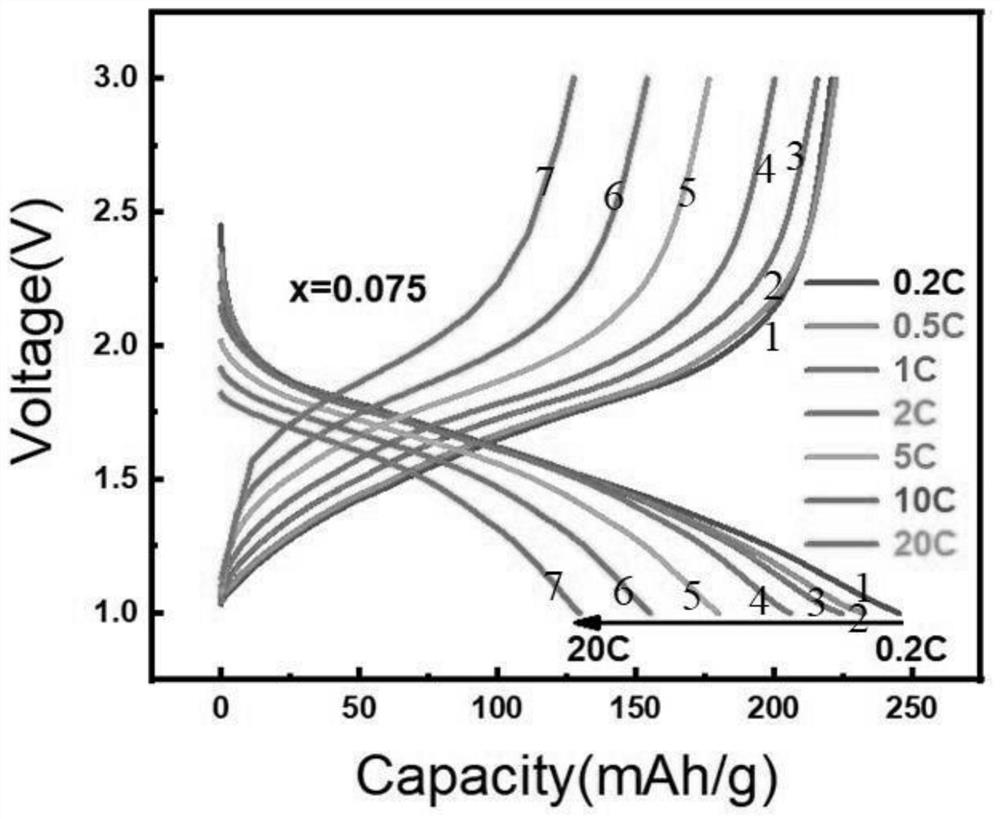

[0022] Example 2: Weigh niobium powder, selenium powder, copper powder and molybdenum powder according to the stoichiometric ratio, the selenium excess is 4%, and the molar ratio of molybdenum and niobium is 1:15.6. Add a certain amount of absolute ethanol, and the solid-to-liquid ratio is 0.4:1. The material was heated in a water bath at 35°C for 3 hours under electromagnetic stirring, and ultrasonically dispersed for 35 minutes. After completion, the material was dried in a blast drying oven. Subsequently, the material was wet-milled for 8 hours, and the ball milling speed was n=400r / min. After the ball milling and dispersion were completed, the ball mill jar was placed in an oven for drying. Then placed in an argon atmosphere and sintered at 600 °C for 6 h to obtain the precursor Cu 2 Mo 0.075 Nb 0.77 Se 4 material, the heating rate is 15°C / min. Precursor Cu 2 Mo 0.075 Nb 0.77 Se 4 The material is placed in a glass tube in the air state and calcined at 700 ° C for ...

Embodiment 3

[0023] Example 3: Niobium powder, selenium powder, copper powder and titanyl sulfate were weighed according to the stoichiometric ratio, the excess of selenium was 3%, and the molar ratio of titanium and niobium was 1:7.6. Add a certain amount of absolute ethanol, the solid-to-liquid ratio is 0.3:1. The material was heated in a water bath at 35°C for 5 hours under electromagnetic stirring, and ultrasonically dispersed for 40 minutes. After completion, the material was dried in a blast drying oven. Subsequently, the material was wet-milled for 6 hours, and the ball milling speed was n=500r / min. After the ball milling and dispersion were completed, the ball mill jar was placed in an oven for drying. Then placed in an argon atmosphere and sintered at 800 °C for 4 h to obtain the precursor Cu 2 Ti 0.15 Nb 0.74 Se 4 material, the heating rate is 12°C / min. Will Cu2 Ti 0.15 Nb 0.74 Se 4 The material is placed in a glass tube in the air state and calcined at 500 ° C for 7 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com