Self-compacting concrete and preparation method thereof

A self-compacting concrete and gravel technology, applied in the field of concrete, can solve the problems of concrete cracks, affecting the strength of dense concrete, and prone to fracture, etc., and achieve the effect of reducing cracks, reducing concrete cracking, and increasing pumping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

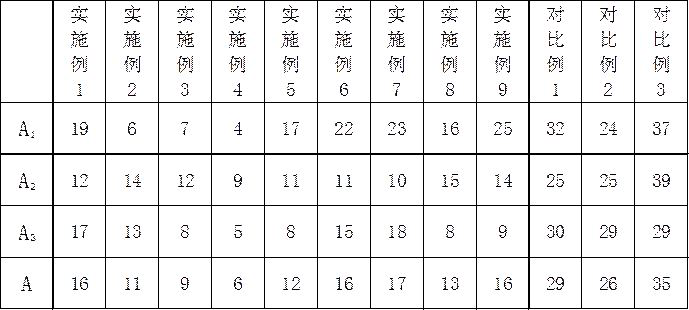

Examples

Embodiment 1

[0039] S1. Weigh 760kg of crushed stone, 820kg of sand and 300kg of P.Ⅱ42.5 cement into the mixer, stir for 15min at a speed of 60r / min, to prepare a primary mixture;

[0040] S2. Weigh 50kg of fly ash, 60kg of slag powder, 15kg of silica fume, 9kg of sodium polyacrylate, 20kg of sodium laurate and add it to the primary mixture in S1, stir at a speed of 60r / min for 20min to prepare a secondary mixture ;

[0041] S3. Add 6kg of SPR-1 pumping agent and 160kg of drinking water into the secondary mixture in S2, and stir at a speed of 60r / min for 30min to prepare self-compacting concrete.

Embodiment 2

[0043] S1. Weigh 830kg of crushed stone, 910kg of sand and 300kg of P.Ⅱ42.5 cement into the mixer and stir for 15min at a speed of 60r / min to prepare a primary mixture;

[0044] S2. Weigh 50kg fly ash, 60kg slag powder, 15kg silica fume, 9kg sodium polyacrylate, 20kg sodium laurate into the primary mixture in S1, stir at 60r / min for 20min to prepare the secondary mixture ;

[0045] S3. Add 9kg of SPR-1 pumping agent and 180kg of drinking water into the secondary mixture in S2, and stir at a speed of 60r / min for 30min to prepare self-compacting concrete.

Embodiment 3

[0047] S1. Weigh 830kg of crushed stone, 910kg of sand and 300kg of P.Ⅱ42.5 cement into the mixer and stir for 15min at a speed of 60r / min to prepare a primary mixture;

[0048] S2. Weigh 55kg fly ash, 65kg slag powder, 30kg silica fume, 9kg sodium polyacrylate, 30kg sodium laurate into the primary mixture in S1, stir at 60r / min for 20min to prepare the secondary mixture ;

[0049] S3. Add 9kg of SPR-1 pumping agent and 180kg of drinking water into the secondary mixture in S2, and stir at a speed of 60r / min for 30min to prepare self-compacting concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com