Mining self-pressurization intelligent wireless anchor cable dynamometer and using method thereof

A wireless anchor and dynamometer technology, applied in the direction of hydraulic/pneumatic measurement, etc., can solve the problems of inaccurate test results, inconvenient use, no impact resistance function, etc., to increase the dustproof and waterproof effect, convenient and stable transmission, The effect of improving service life and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

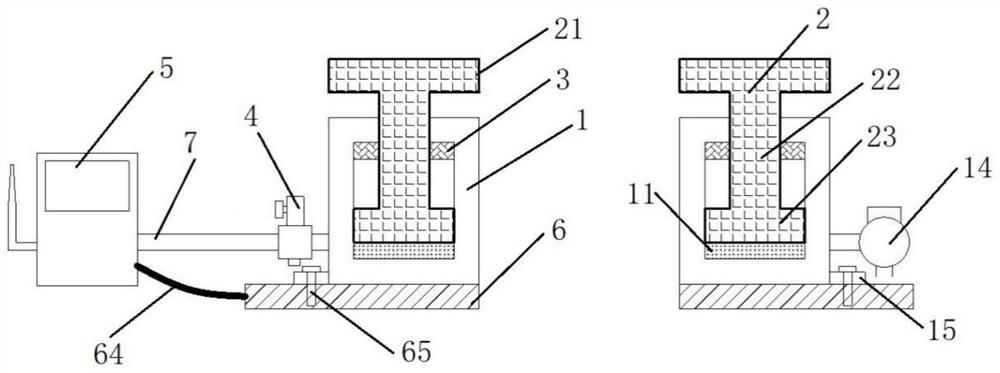

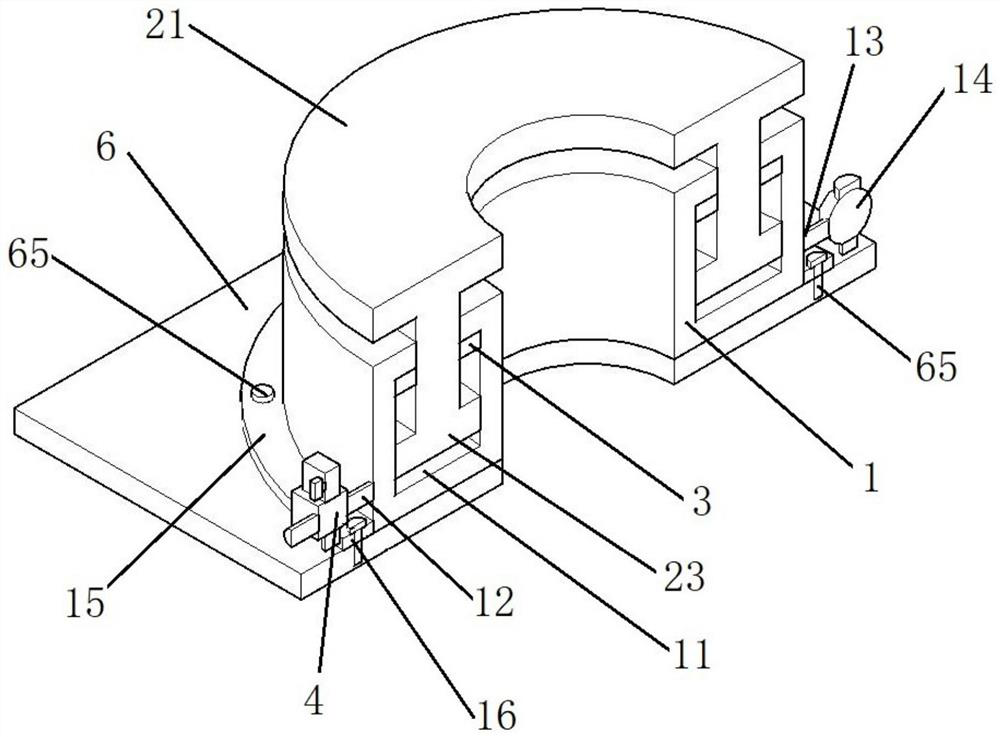

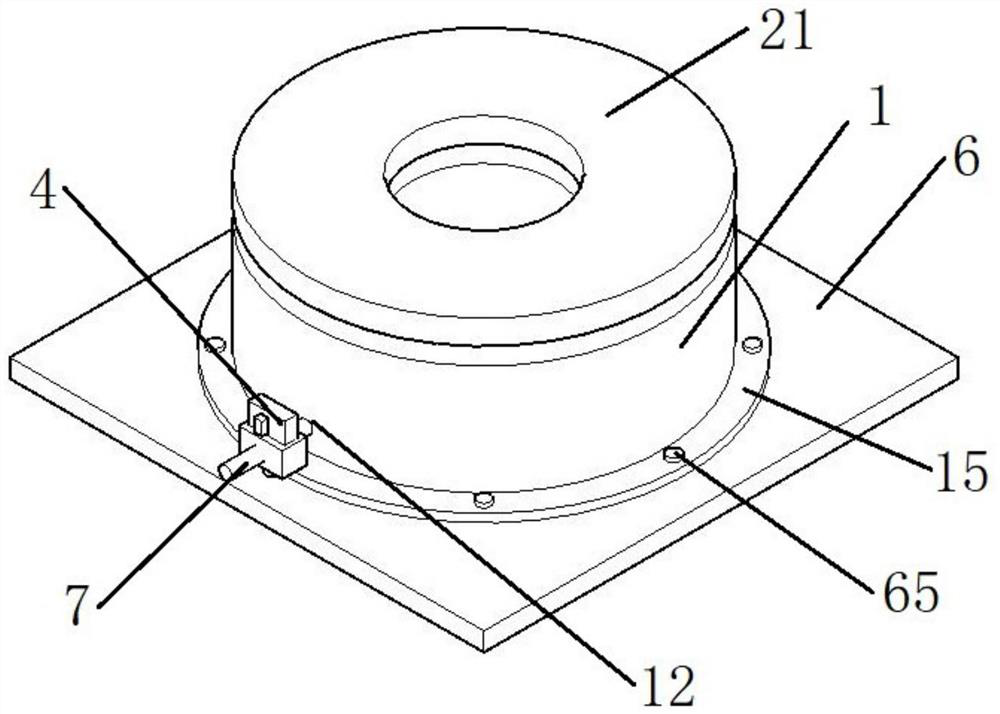

[0036] A mining self-pressurization intelligent wireless anchor cable dynamometer, comprising an oil cylinder outer body 1, a telescopic body 2, a first sealing ring 3, a tee joint 4, a meter head 5, an intelligent tray 6 and a high-pressure oil pipe 7, the The outer body 1 of the oil cylinder is installed on the intelligent tray 6, the telescopic body 2 is installed inside the outer body 1 of the oil cylinder and sealed with the first sealing ring 3, the outer body 1 of the oil cylinder is connected with the meter head 5 through the high-pressure oil pipe 7, and the tee joint 4 is installed On the high-pressure oil pipe 7, this product can resist impact, have stable test results, convenient data recording and transmission, and convenient pressurization or tensioning. Force analysis and monitoring to better guide the support construction, evaluate and test the support effect.

[0037] For ease of use, the oil cylinder outer body 1 includes an oil storage chamber 11, an oil cyl...

Embodiment 2

[0048] A mining self-pressurization intelligent wireless anchor cable dynamometer, comprising an oil cylinder outer body 1, a telescopic body 2, a first sealing ring 3, a tee joint 4, a meter head 5, an intelligent tray 6 and a high-pressure oil pipe 7, the The outer body 1 of the oil cylinder is installed on the intelligent tray 6, the telescopic body 2 is installed inside the outer body 1 of the oil cylinder and sealed with the first sealing ring 3, the outer body 1 of the oil cylinder is connected with the meter head 5 through the high-pressure oil pipe 7, and the tee joint 4 is installed The high-pressure oil pipe 7 solves the problems of cumbersome force measurement and transmission records of anchor cables used in coal mines, lack of impact resistance, and troublesome tension and fastening. It also has the advantages of convenient pressurization, automatic collection and recording, and efficient and convenient transmission.

[0049] In order to ensure the use effect, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com