Circuit breaker

A circuit breaker and circuit board technology, which is applied to circuit breaker components, circuits, and protection switch components, etc., can solve the problems of large overall space size, unreliable position detection, and inappropriate transmission, etc., so as to facilitate the overall design and layout, the internal layout design is reasonable, and the effect of reducing the overall specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

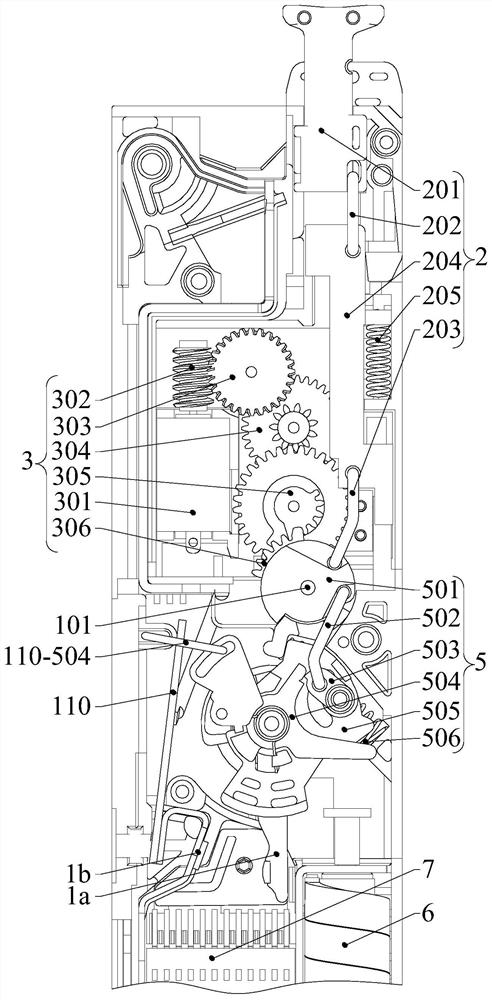

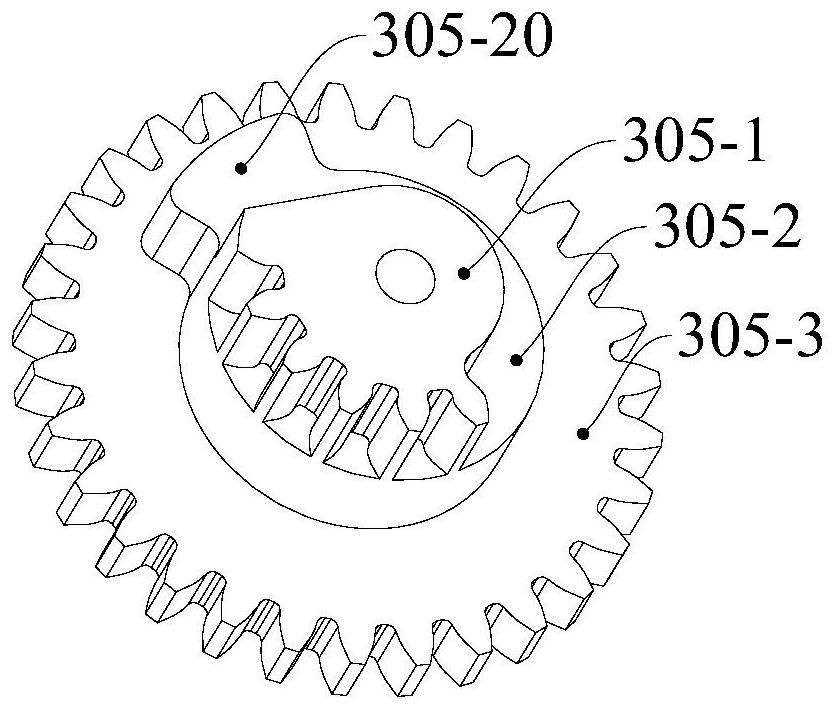

[0057] Such as Figure 1-20 Shown is the first embodiment of the circuit breaker of the present invention, which is the first embodiment of the first type of circuit breaker.

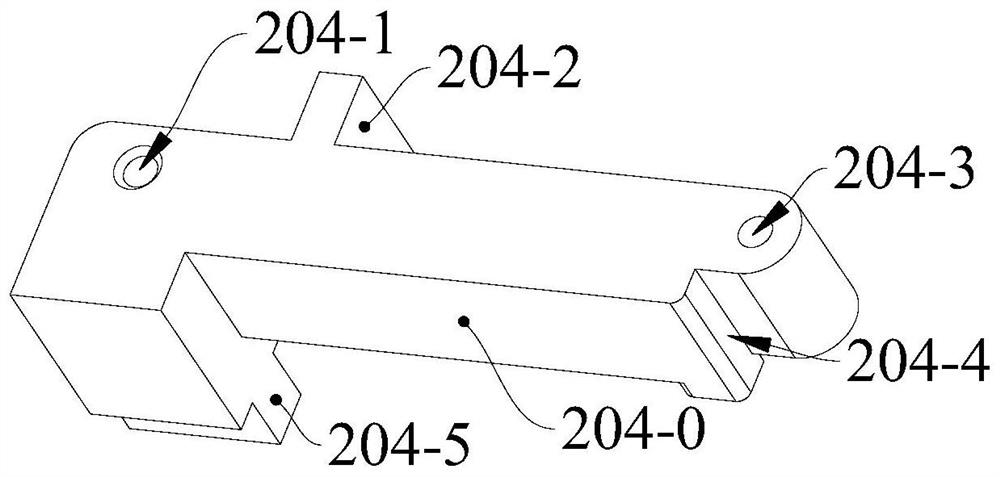

[0058] Such as figure 1 , 9 As shown in -12, the circuit breaker of the present invention includes a circuit breaker casing 1 and a button mechanism 2, an electric mechanism 3 and an operating mechanism 5 arranged in the circuit breaker casing 1. Drive the circuit breaker to close / open to realize manual opening and closing; the electric mechanism 3 cooperates with the button mechanism 2 and or the operating mechanism 5 to drive the circuit breaker to close / open through the operating mechanism 5 to realize automatic opening and closing.

[0059] preferred, such as figure 1 As shown, the electric mechanism 3 drives and cooperates with the transmission part 501 of the operating mechanism 5 to realize closing of the circuit breaker, and drives and cooperates with the button mechanism 2 to realize opening o...

no. 3 example

[0088] preferred, such as Figure 14-16 Shown is the third embodiment of the circuit breaker of the present invention, which is the third embodiment of the first circuit breaker.

[0089] Such as Figure 14-16 As shown, the difference between this embodiment and the circuit breaker of the first embodiment is that the circuit breaker also includes a manual-automatic switching device arranged in the circuit breaker casing 1 . The circuit breaker is a plug-in circuit breaker, and the circuit breaker housing 1 is basically a parallelepiped structure, including a circuit breaker operation interface 1i arranged at one end thereof, a button assembly hole and an outlet terminal 881 arranged on the circuit breaker operation interface 1i , one end of the button mechanism 2 is inserted in the button assembly hole, and the other end of the circuit breaker housing 1 is provided with an incoming line terminal 880; the circuit breaker also includes a manual-automatic switching device arranged...

no. 4 example

[0107] preferred, such as figure 1 , 17 -20 shows the fourth embodiment of the circuit breaker of the present invention, which is the fourth embodiment of the first circuit breaker.

[0108] preferred, such as figure 1 , 17As shown in and 18, the circuit breaker includes a circuit breaker case 1, and a button mechanism 2, an electric mechanism 3, an operating mechanism 5, a protection mechanism, an arc extinguishing system 7, a current sampling device 112, and an incoming line terminal arranged in the circuit breaker case 1 880 and outlet terminal 881; the button mechanism 2 drives the circuit breaker to close / open through the operating mechanism 5; the electric mechanism 3 drives the circuit breaker to close / open through the button mechanism 2 and or the operating mechanism 5; the protection The mechanism cooperates with the operating mechanism 5 to trigger the tripping of the circuit breaker; the incoming terminal 880 and the outgoing terminal 881 are respectively arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com